Cloth guide device of loom

The technology of a cloth guide device and a loom is applied in the directions of transportation and packaging, winding strips, and thin material processing, which can solve the problems of poor cloth conveying effect, low work efficiency, inconvenient disassembly and assembly, etc. Simple structure and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

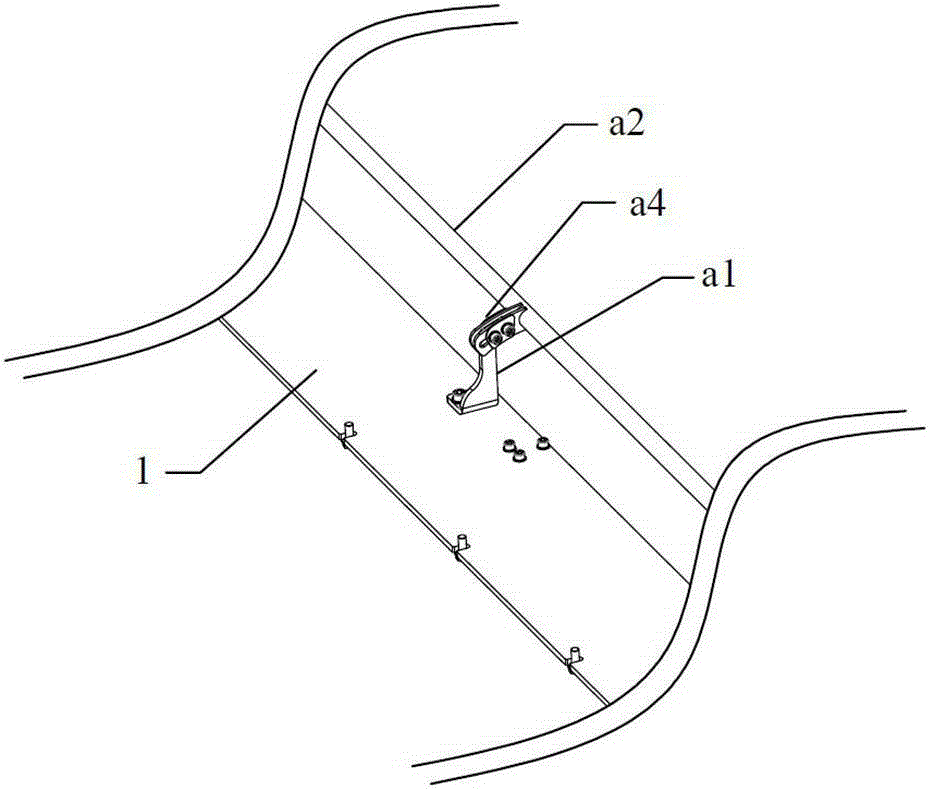

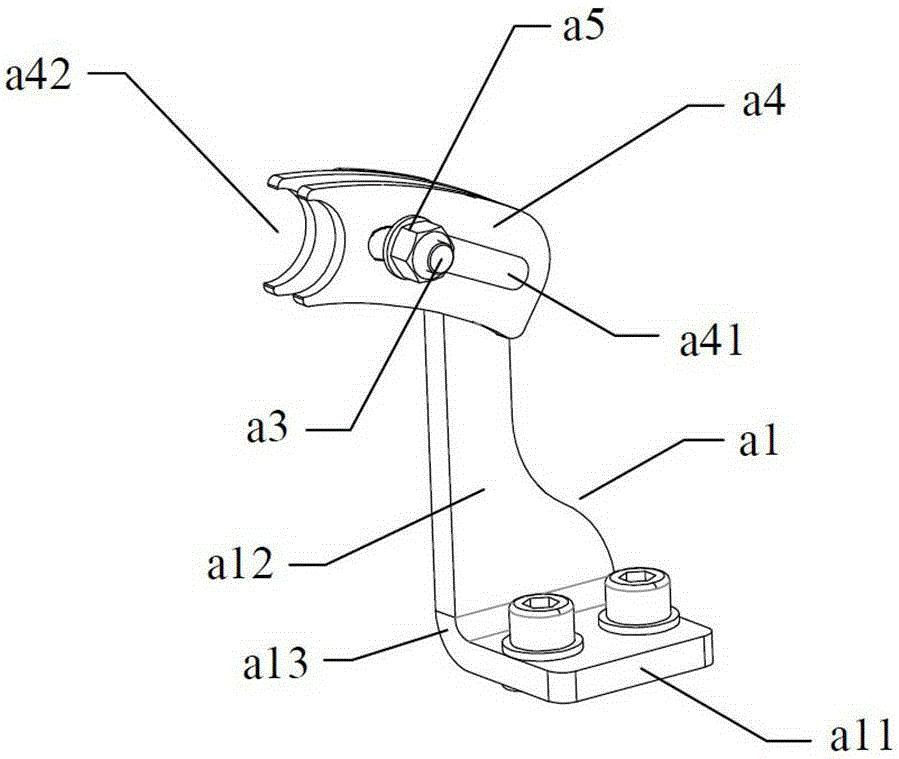

[0017] Example 1: See figure 1 , figure 2 , A cloth guiding device of a loom, comprising a bottom plate 1, a mounting seat a1 provided on the bottom plate 1, an adjusting mechanism provided on the mounting seat a1, and a cloth guide roller a2 provided on the adjusting mechanism. The mounting seat a1 is provided with Mounting hole a14, the adjusting mechanism includes a supporting rod a3 connected to the mounting hole a14 and an adjusting piece a4 movably connected to the supporting rod a3, and a cloth guide roller a2 is provided on the adjusting piece a4. The adjusting piece a4 is provided with a front end nip roller space a42 for installing the cloth guide roller a2.

[0018] The mounting base a1 includes a fixed bottom a11, a supporting part a12 and a bending connection part a13. The fixed bottom a11 is fixedly connected to the bottom plate 1, and the supporting part a12 and the fixed bottom a11 are connected to each other through the bending connection part a13. The fixed bot...

Embodiment 2

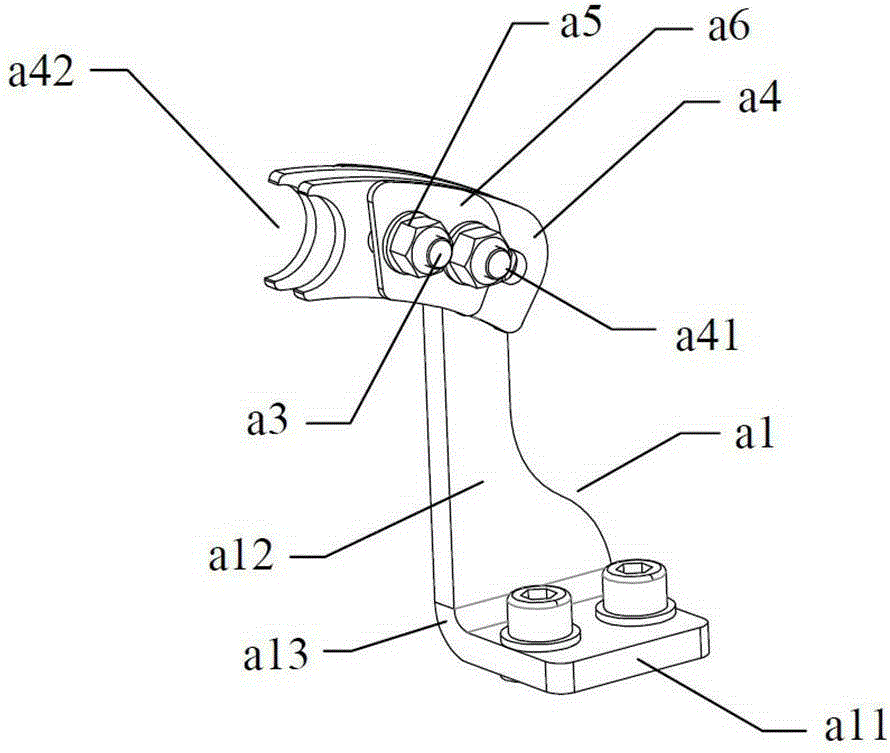

[0019] Example 2: See figure 2 The main difference between the first embodiment and the first embodiment is that the adjustment piece a4 is provided with a long hole section a41, the support rod a3 has two, the support rod a3 is covered with a clip a6, and the support rod a3 is provided with an end A screw thread and an adjusting nut a5 connected with the end of the screw thread for tightening or loosening the clip a6 and the adjusting piece a4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com