One-component addition type liquid silicone rubber and preparation method thereof

A liquid silicone rubber, one-component technology, applied in the field of silicone gel, can solve the problem of high production cost, achieve the effects of low cost, save production cost, and improve storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

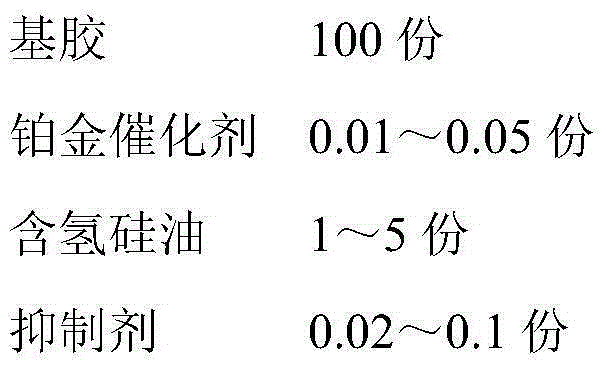

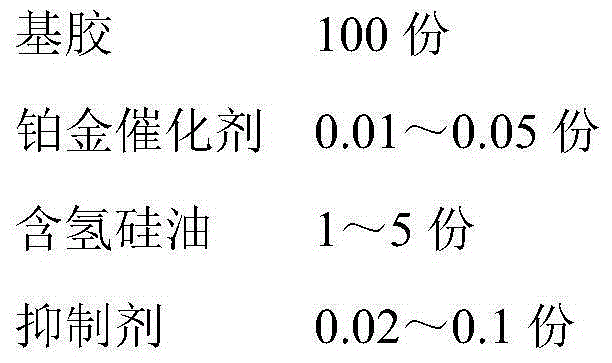

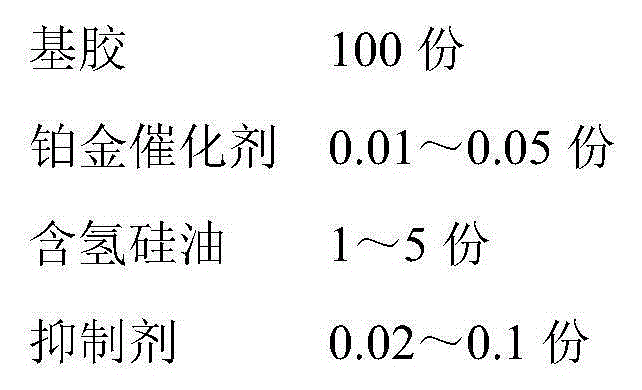

[0035] The preparation method of the above-mentioned one-component addition type liquid silicone rubber is:

[0036] (1) Preparation of base rubber: Add 100 parts by mass of vinyl silicone oil into the kneader and stir at room temperature for 0.5-1h, add MQ silicone resin with a formula amount of 25%-50% and stir for 0.5-1h, then add the remaining MQ silicone resin, and continue stirring 3 to 5 hours to obtain base rubber;

[0037] (2) Add 100 parts by mass of rubber base, 1 to 5 parts by mass of hydrogen-containing silicone oil, and 0.01 to 0.05 parts by mass of inhibitor into the stirring tank, and mix well;

[0038] (3) Add 0.01 to 0.05 parts by mass of platinum catalyst to step (2), and mix uniformly;

[0039] (4) The product is molded and vulcanized on a flat vulcanizer, the vulcanization temperature is 100-140° C., and the vulcanization time is 5-10 minutes to obtain the one-component liquid silicone rubber.

Embodiment 1

[0041] The vinyl silicone oil involved in this example is a vinyl-terminated polysiloxane with a viscosity of 1000mPa.s at 25°C and a vinyl mass content of 1.2%; MQ silicone oil has a viscosity of 200mPa.s at 25°C and a vinyl The mass content is 2.5% vinyl-containing MQ silicone resin; the platinum mass content of the platinum catalyst is 2000ppm; the hydrogen-containing silicone oil has a viscosity of 300mPa.s at 25°C and a hydrogen-containing polysiloxane with a hydrogen mass content of 1.0%; The inhibitor is compounded and modified by heptamethylcyclotetrasiloxane and ethynyl-1-cyclohexanol in a molar ratio of 1 to 2 under the action of chloroplatinic acid.

[0042] The preparation method of vinyl silicone oil is as follows: mix 100 parts by mass of octamethylcyclotetrasiloxane and 3 parts by mass of tetramethyldivinyldisiloxane, add 0.03 parts by mass of catalyst tetramethylhydrogenation under stirring ammonium, the temperature was raised to 120°C for 2 hours of polymeriza...

Embodiment 2

[0054] The vinyl silicone oil involved in this example is a vinyl-terminated polysiloxane with a viscosity of 500mPa.s at 25°C and a vinyl mass content of 1.6%; MQ silicone oil has a viscosity of 500mPa.s at 25°C and a vinyl The mass content is 2.0% vinyl-containing MQ silicone resin; the platinum mass content of the platinum catalyst is 3000ppm; the hydrogen-containing silicone oil is a hydrogen-containing polysiloxane with a viscosity of 60mPa.s at 25°C and a hydrogen mass content of 1.5%; The inhibitor is compounded and modified by heptamethylcyclotetrasiloxane and ethynyl-1-cyclohexanol in a molar ratio of 1 to 1 under the action of chloroplatinic acid.

[0055] The preparation method of vinyl silicone oil is as follows: 100 parts by mass of octamethylcyclotetrasiloxane and 0.1 part by mass of tetramethyldivinyldisiloxane are mixed, and 0.01 part by mass of catalyst tetramethylhydrogenation is added under stirring ammonium, heated to 100°C for 4 hours, then raised to 150°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com