A wharf concrete road structure and its construction method

A technology for concrete roads and wharves, applied to roads, roads, road signs, etc., can solve problems such as difficulty in ensuring safety and durability, large cumulative traffic volume, and heavy vehicles, so as to ensure safety and durability , the thickness of the whole board is uniform, and the effect of saving engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with drawings and embodiments.

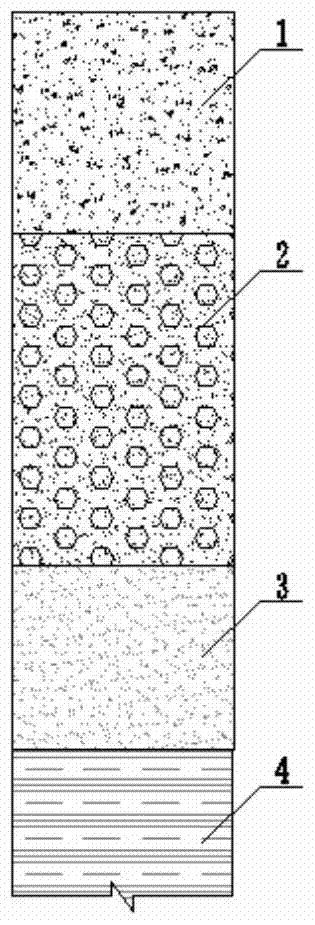

[0051] The present embodiment wharf concrete road structure, as figure 1As shown, above the roadbed 4, lay respectively 25cm thick cushion course 3,45cm thick base course 2 and 30cm thick surface course 1, the total width of road is 850cm.

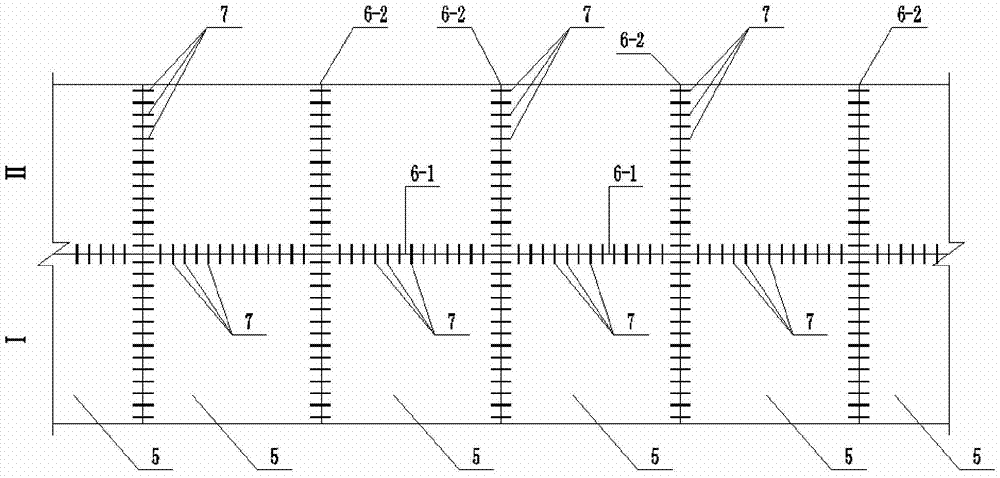

[0052] Such as figure 2 As shown, the concrete is divided into two lanes with a width of 425cm along the center line of the road, in which lane 1 is the incoming goods lane, and lane 2 II is the return lane. The surface layer 1 of the two lanes is divided into several pieces of concrete cast-in-place roadway slabs 5 according to the longitudinal length (the length along the longitudinal direction of the road) of 450cm and the transverse width (the length along the transverse direction of the road) of 425cm. -1 (gap along the longitudinal direction of the road) and transverse joint 6-2 (gap along the transverse direction of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com