Construction method of cast-in-place pile with combination of full-sleeve and mud protecting wall

A technology of mud wall protection and construction method, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as slow speed, and achieve the effects of ensuring pile quality, improving construction efficiency, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

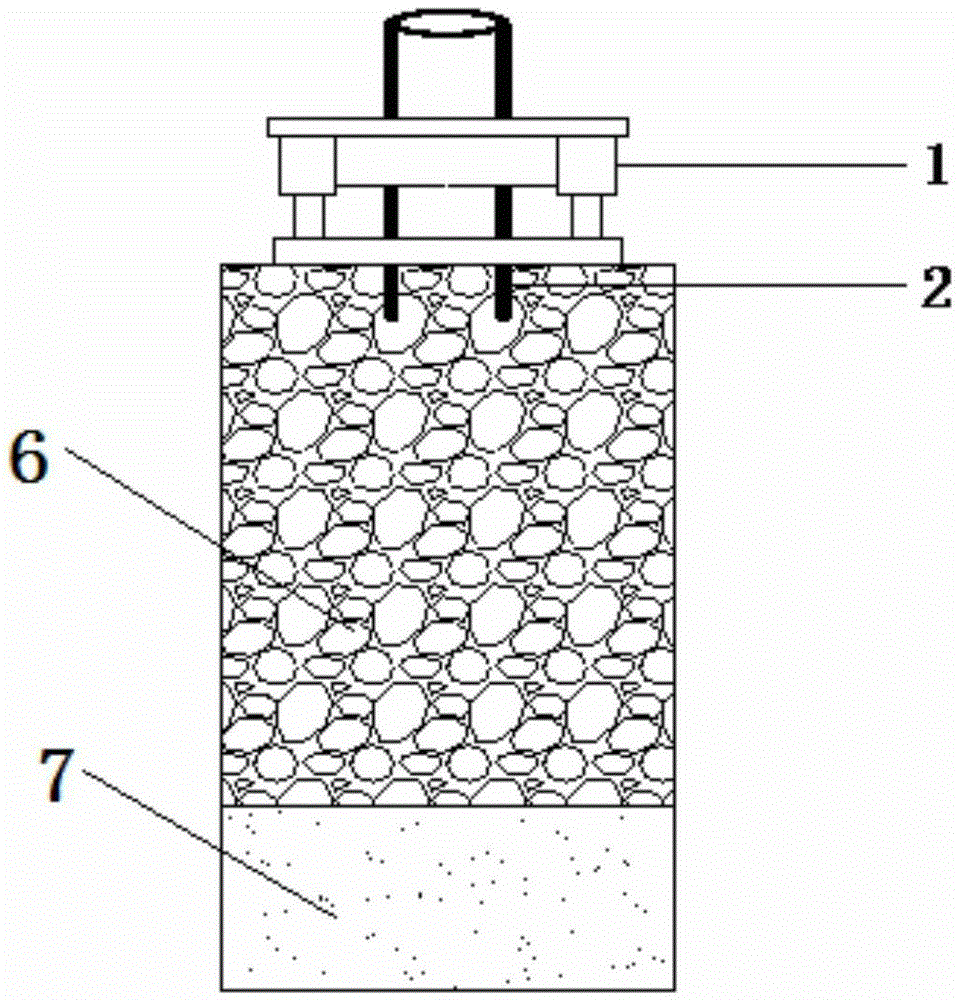

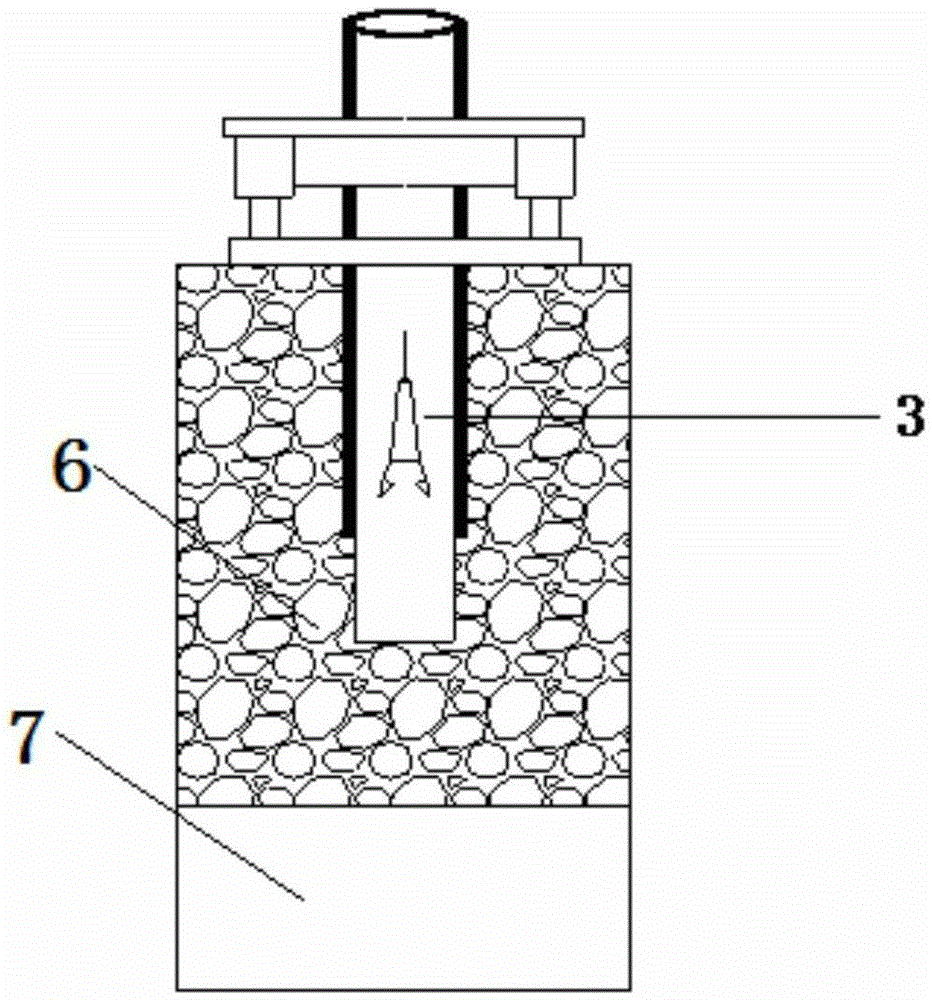

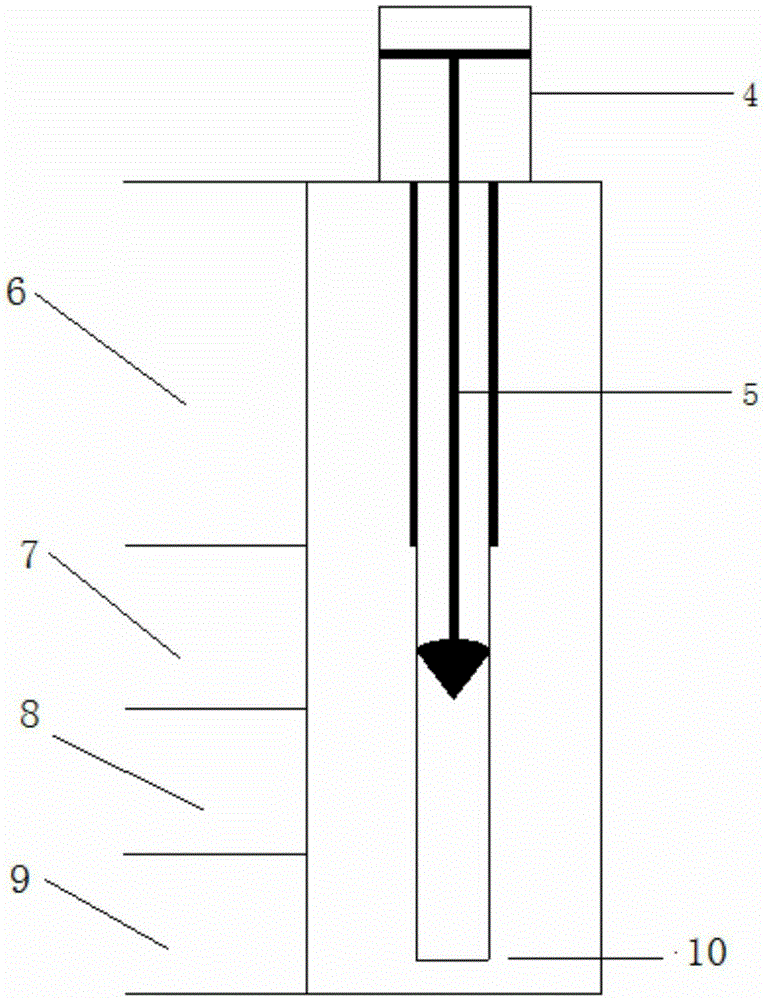

[0033] Such as Figure 1~3 As shown, in a pile foundation project, the designed pile length of the cast-in-situ pile is 65m, and the pile diameter is 1000mm. The geological conditions within the scope of the pile length are, from top to bottom, the obstacle layer containing masonry stones, clay layer, silt layer, and pebble layer. Before the construction of cast-in-situ piles, the underground obstacles should be cleaned up. During the construction of this project, the construction method of cast-in-situ piles with full casing combined with mud wall protection is adopted, which not only ensures the quality of the piles, but also improves the construction efficiency and effectively reduces the construction cost.

[0034] The cast-in-situ pile construction method adopting the combined mud wall of the full casing mainly includes the following steps:

[0035] Step 1. Investigate the underground obstacles at the required piling site, and find out the type, size and buried depth of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com