Waterproof structure of fine stone concrete dividing joint

A technology of fine stone concrete and grid joints, applied in the direction of roof insulation materials, etc., can solve the problems of grid joint leakage and insufficient waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

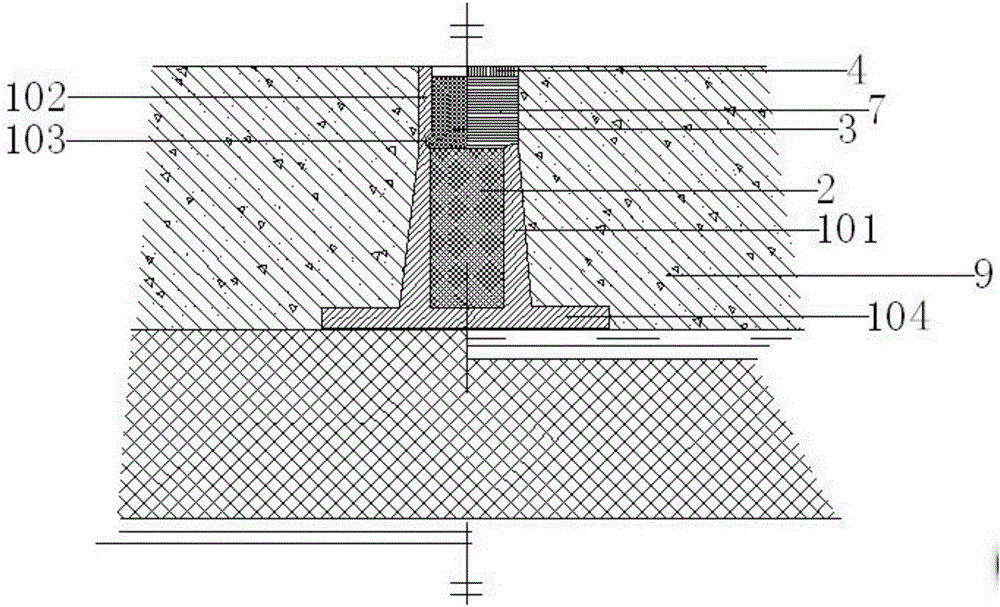

[0019] The specific implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] A fine stone concrete grid joint waterproof structure, comprising a pre-installed mold strip 1, the skeleton of the pre-installed mold strip 1 is made of weather-resistant PVC, and the horizontal part 104 of the pre-installed mold strip is arranged on the fine stone concrete protective layer 9, the vertical part extends upwards, and after the pre-installed mold strip 1 is poured into the fine stone concrete 9 and hardened, the upper section 102 of the pre-installed mold strip 1 is removed.

[0021] Specifically, as figure 1 As shown, the pre-installed mold strip 1 is in an inverted T shape and is integrally injection molded. Contains the mold bar horizontal section 104, the vertical mold bar upper section 102, and the mold bar lower section 102, and the mold bar upper section 102 and the mold bar lower section 101 are co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com