Coaxial reverse cable tunnel drilling device

A drilling device and reverse technology, applied in tunnels, earth-moving mining, mining equipment, etc., can solve the problems of limited laying distance, damage to surface vegetation, complicated construction, etc., to reduce friction, improve driving speed, increase The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

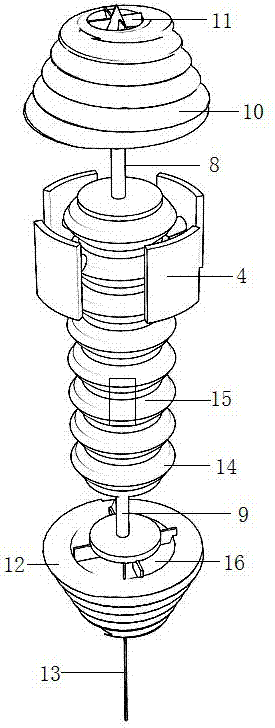

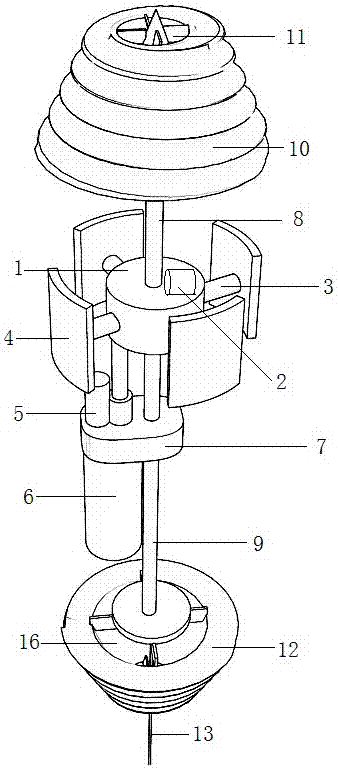

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] like figure 1 As shown, the coaxial reverse cable tunnel drilling device includes a positioning device located in the middle, a drilling device located in the upper part, and a balance clearing device located in the lower part; the positioning device includes a chuck 1 and a step for driving the chuck 1 Enter the motor 2; the side wall of the chuck 1 has at least three claws 3 evenly distributed in the circumferential direction; an arc-shaped top plate 4 is installed at the end of each claw 3; the lower end of the chuck 1 is connected with an electric push rod The output end of 5 is connected; the lower end of the electric push rod 5 is equipped with a drive motor 6; the output end of the drive motor 6 is connected with a coaxial reverse gearbox 7; the forward output end at the top of the coaxial reverse gearbox 7 A transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com