Auxiliary refrigerating device for oil press

A technology for auxiliary refrigeration and hydraulic presses, applied in the directions of fluid pressure actuation devices, mechanical equipment, fluid pressure actuation system components, etc. efficiency and other issues, to achieve the effect of improving product production efficiency, saving raw materials, and enhancing the strength of tubing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

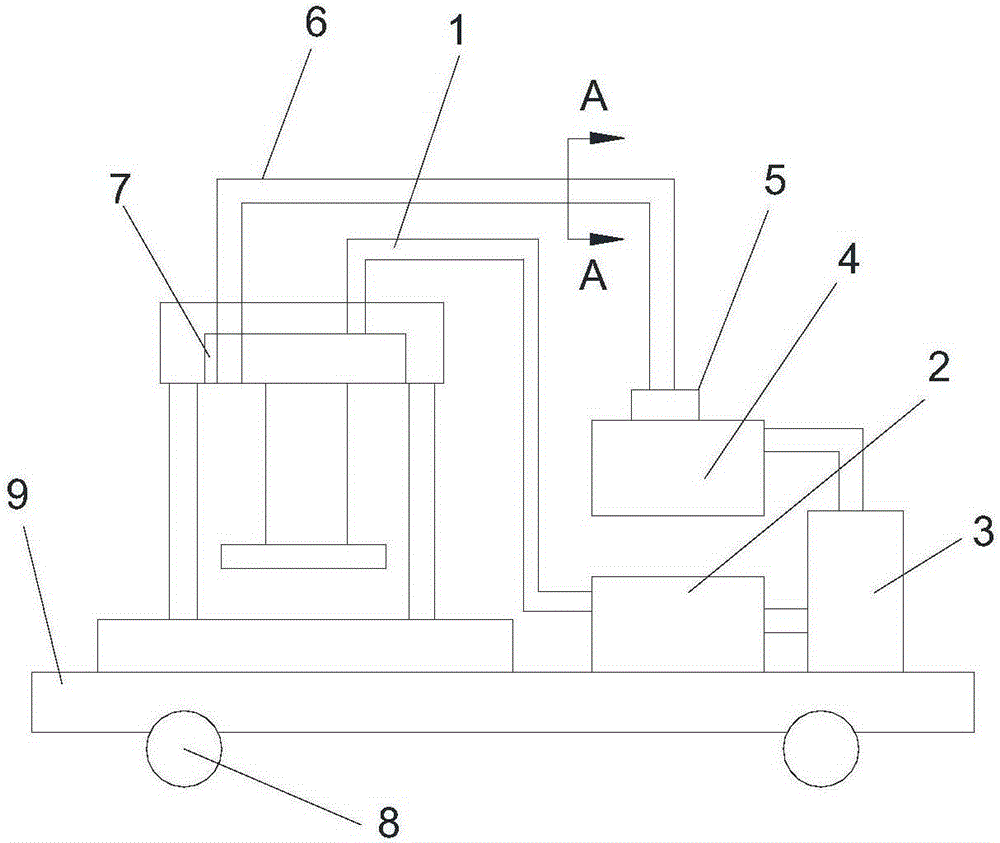

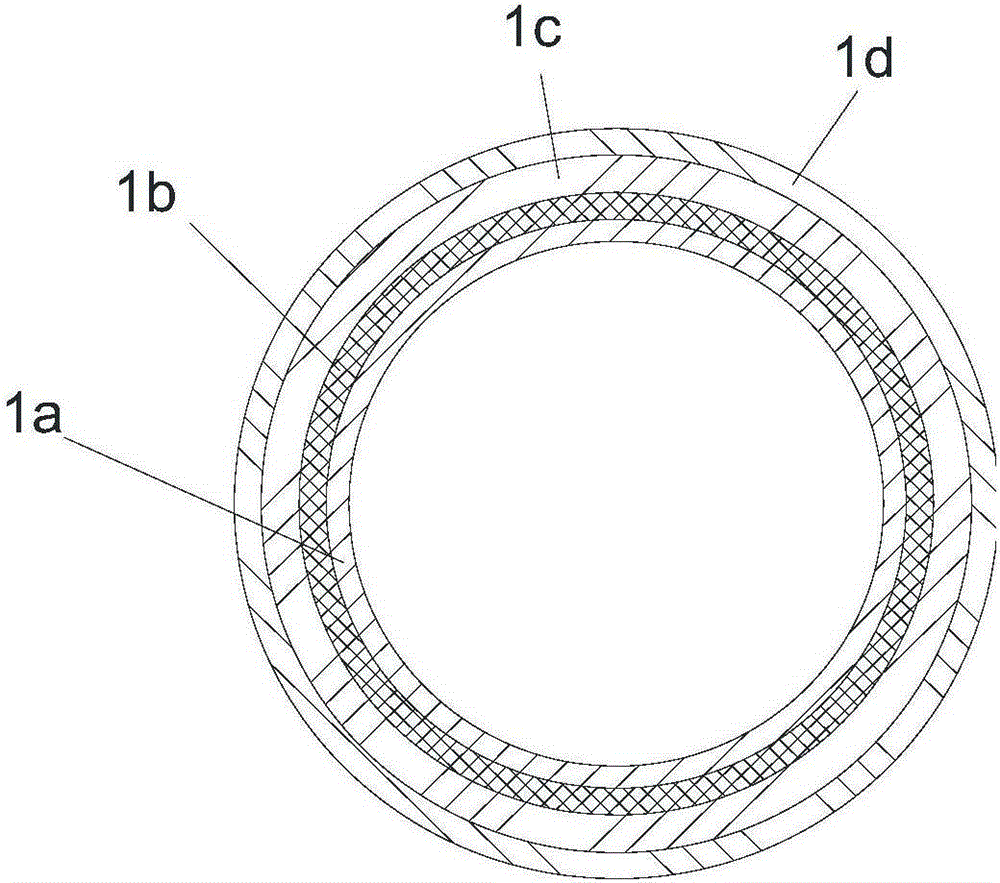

[0016] Such as figure 1 with figure 2 As shown, the hydraulic auxiliary refrigeration device of the present embodiment includes a base 9 and a hot oil pipe 1, a hot oil tank 2, a refrigerator 3, a cold oil tank 4, an oil pump 5, a cold oil pipe 6 and a hydraulic oil tank 7 arranged on the base 9. One end of the oil pipe 1 is connected with the hydraulic oil tank 7, and the other end leads to the hot oil tank 2, and one end of the hot oil tank 2 is provided with a refrigerator 3, and the other end of the refrigerator 3 is provided with a cold oil tank 4, and the upper end of the cold oil tank 4 is provided with an oil pump 5, an oil pump 5 The cold oil pipe 6 leads to the hydraulic oil tank 7; the bottom of the base 9 is provided with a moving roller 8; the hot oil pipe 1 and the cold oil pipe 6 both include an inner rubber layer 1a and a reinforcement layer 1b arranged in sequence from the inside to the outside and the outer rubber layer 1c, the reinforcement layer 1b is a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com