Digital hologram-based high-precision spherical surface sub-aperture splicing fusion method

A digital hologram and aperture splicing technology, which is applied to measurement devices, instruments, and optical devices, etc., can solve problems such as measurement result errors, and achieve the effects of accurate phase value, simple calculation process, and improved accuracy and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

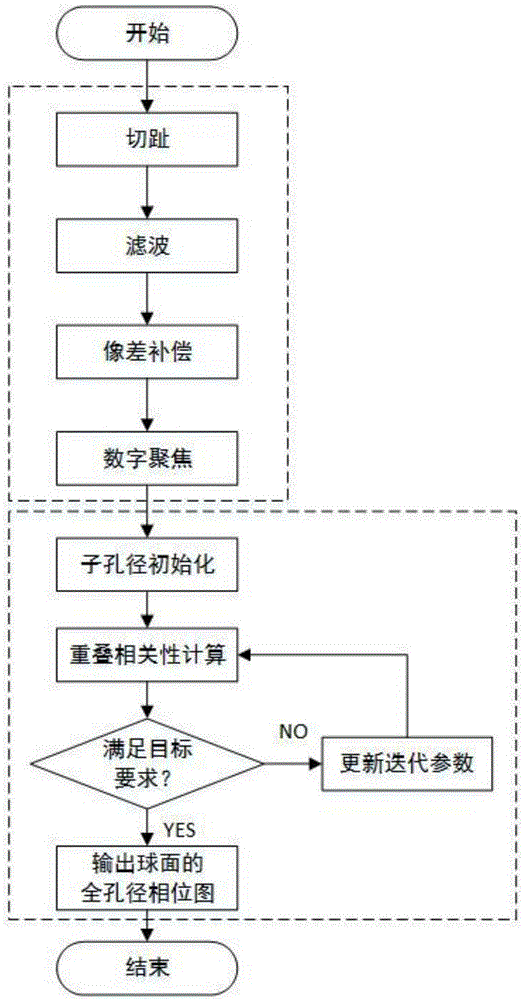

[0028] The present invention is a high-precision spherical sub-aperture splicing and fusion method based on digital holograms. Firstly, the digital reproduction calculation is performed on the sub-aperture holograms obtained based on the off-axis holographic optical path, and the mathematical model of the system optical path and positioning error is used to correct the positioning error due to positioning errors. The phase aberration introduced by the error is digitally corrected to obtain the phase map of each sub-aperture; then, the sub-aperture phase map is spliced and fused by using the sub-aperture stitching algorithm, and the relative position error of the sub-aperture is further corrected to obtain the phase map of the spherical full aperture , the process is as figure 1 shown, including the following steps:

[0029] The first step is to dig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com