Rubber strip production control device

A technology for production control and rubber strips, applied in the field of control systems, can solve the problems of waste products, asynchronous setting and adjustment of process parameters, restricting the improvement of production efficiency and product quality, etc. The effect of improving the stable running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

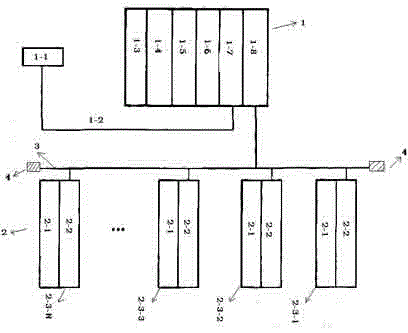

[0008] During the operation of the production line, the CPU 1-4 of the master station 1 executes the PLC control program, constantly refreshes the data received in the register, and provides the data in the register to the upper PC 1-1.

[0009] During data acquisition and monitoring, the analog parameters (temperature, current, rotational speed, pressure and speed, etc.) collected by the sensors of each device are converted by A / D, and the digital quantities are transferred to the register of FX2NPLC2-1, and the master station 1 CPU1-4 reads the corresponding parameters from the registers of FX2NPLC2-1 according to a certain frequency through the CC-Link bus 3 network. When setting the operating parameters of the equipment, Q02HCPU1-4 sends the parameters to be set to the corresponding registers of FX2NPLC2-1 of the corresponding equipment through the CC-Link bus 3 network. Convert, drive the actuator to complete the parameter setting.

[0010] The invention realizes real-ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com