A kind of gan device and its manufacturing method

A device and nucleation layer technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as large stress, sensor fabrication, cracks, etc., achieve early warning of excessive local electric field, ensure normal operation, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] By providing a GaN device and a manufacturing method thereof, the present invention can effectively manufacture electrodes in the GaN layer, thereby achieving the technical effect of not affecting the working state of the GaN device.

[0028] In order to solve the above-mentioned technical problems, the above-mentioned technical solutions will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

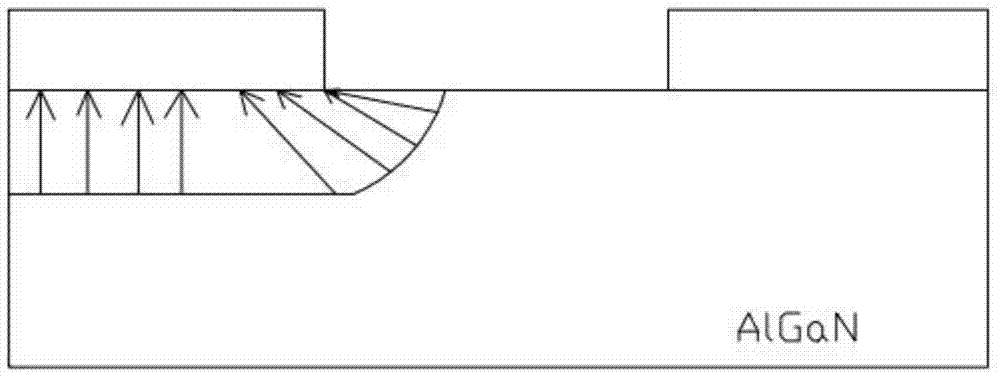

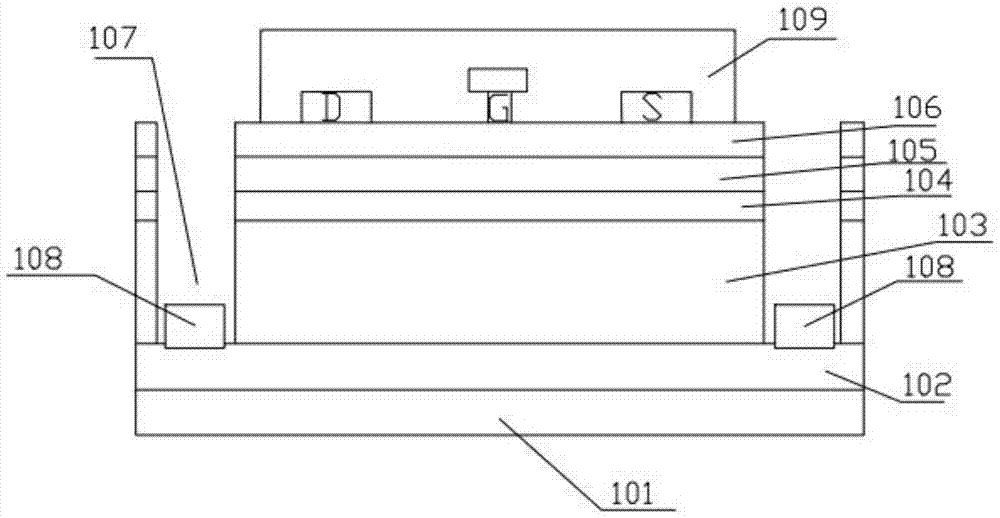

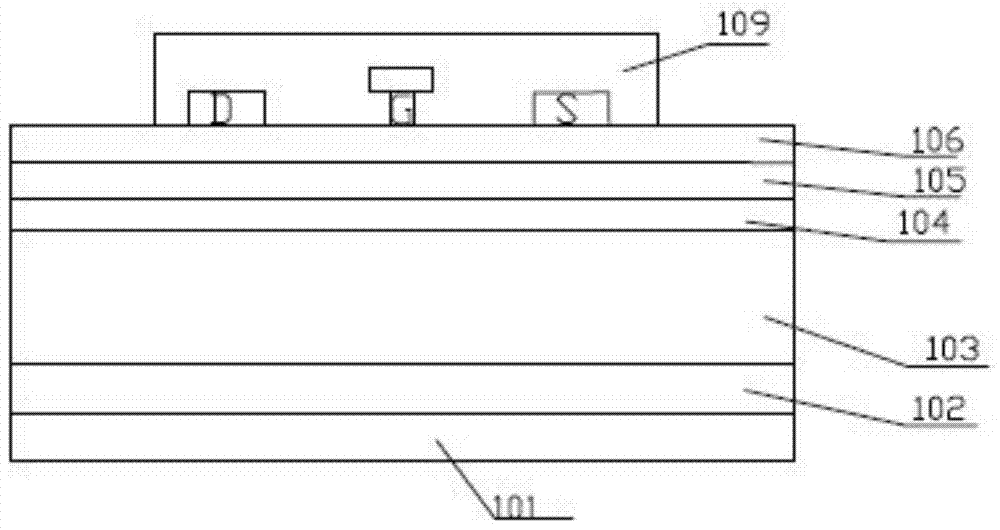

[0029] An embodiment of the present invention provides a GaN device, such as figure 2 As shown, it includes a substrate 101, an AlN nucleation layer 102, a GaN transition layer 103, an AlN isolation layer 104, an AlGaN barrier layer 105, and a GaN cap layer 106 arranged in sequence from bottom to top, and the device on the GaN cap layer 106 The gate G, the source S and the drain D are arranged in a region, and a groove 107 is opened in the detection region on both sides of the device region, and the groove 107 is embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com