Cleaning device for cooling water coil pipe of coal milling speed reducer of thermal power plant

A technology for cooling water coils and cleaning devices, applied in the direction of using liquid cleaning methods, cleaning hollow objects, cleaning methods and appliances, etc., can solve problems such as corrosion, scaling and blockage, and achieve low cleaning costs, safe and simple cleaning operations, The effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

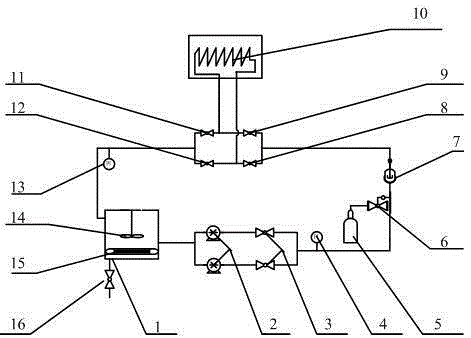

[0014] See accompanying drawing, a kind of cooling water coil cleaning device of coal grinding reducer of the present invention includes cleaning barrel 1, compressed carbon dioxide bottle 5, ultrasonic disturbance device 7, agitator 14, electric heater 15 and two cleaning pumps 2. Among them, the cleaning barrel 1 has a diameter of 600mm and a height of 800mm, and is made of PVC material; the material of the compressed carbon dioxide bottle 5 is stainless steel material for general industrial use; Sweeping type agitator; electric heater 15 adopts the O-type tube insertion electric heater with the power of 10KW designed and produced by Xi'an Minghua Technology Co., Ltd. which is commercially available, and the electric heater 15 is located at the bottom of the cleaning bucket 1; The cleaning pumps 2 are commercially available fluoroplastic magnetic acid-resistant cleaning pumps with a power of 4KW. The input ends of the two cleaning pumps 2 are connected in parallel to the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com