Stainless steel submerged-arc welding strip with improved room temperature tensile strength

A tensile strength, stainless steel technology, applied in the direction of arc welding equipment, welding equipment, welding medium, etc., can solve the problems that cannot meet the product requirements, the tensile strength cannot meet the technical requirements, etc., and achieve the effect of improving the tensile strength at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

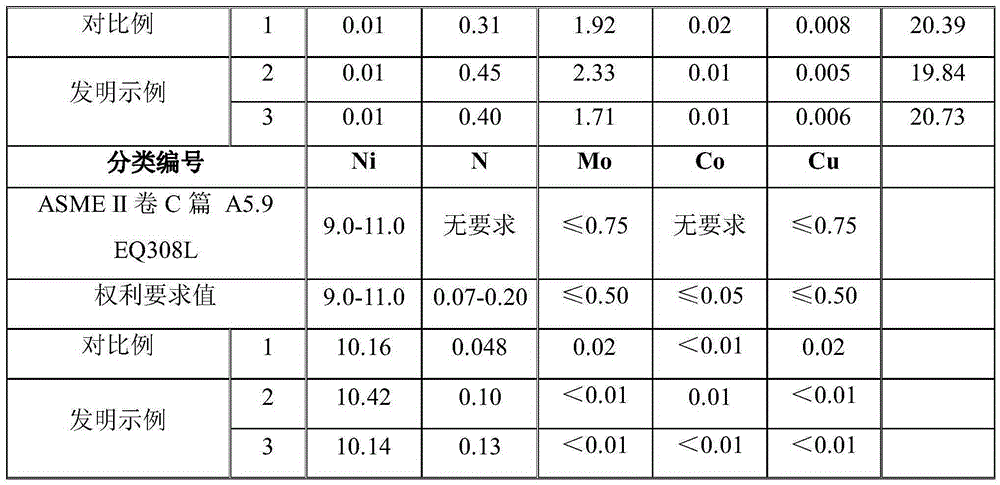

[0013] Example 1, the mass percent of stainless steel submerged arc welding strip is: C≤0.10, Si: 0.45, Mn: 2.23, S≤0.005, P≤0.01, Cr: 19.84, Ni: 10.42, Mo≤0.01, Cu≤ 0.01, Co≤0.01, N: 0.10, the rest is Fe.

Embodiment 2

[0014] Example 2, the mass percentage of stainless steel submerged arc welding strip is: C≤0.10, Si:0.40, Mn:1.71, S≤0.006, P≤0.01, Cr:20.73, Ni:10.14, Mo≤0.01 , Cu≤0.01, Co≤0.01, N: 0.13, and the rest is Fe.

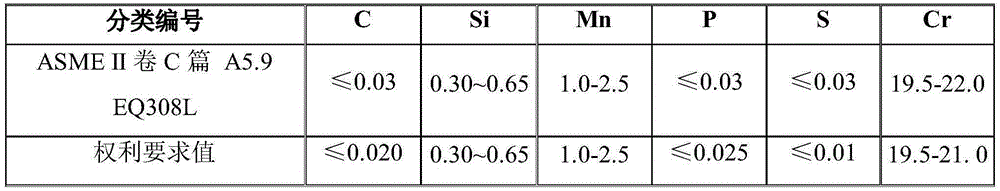

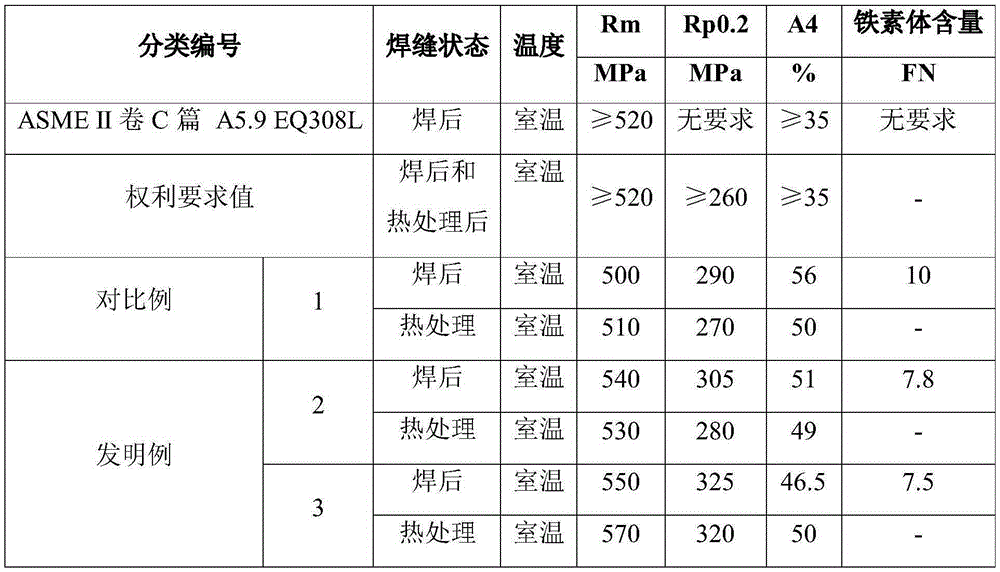

[0015] In order to determine the applicability of the present invention, 3 kinds of welding strips are selected for testing, and the comparative examples and invention examples are respectively explained. The chemical composition of the 3 kinds of welding strips meets the technical requirements of American Standard ASMEII volume C chapter A5.9-2007 at the same time, and the specific results See Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com