Low-cycle fatigue cracking equipment with multi-spindle driven by the end cam of the split connecting rod

A technology of end face cam and low cycle fatigue, which is applied in the field of connecting rod cracking processing, can solve the problems of affecting the loading speed of the cracking cylinder, low cracking efficiency, limited application, etc., and achieve the goal of reducing energy consumption, wide application range and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings.

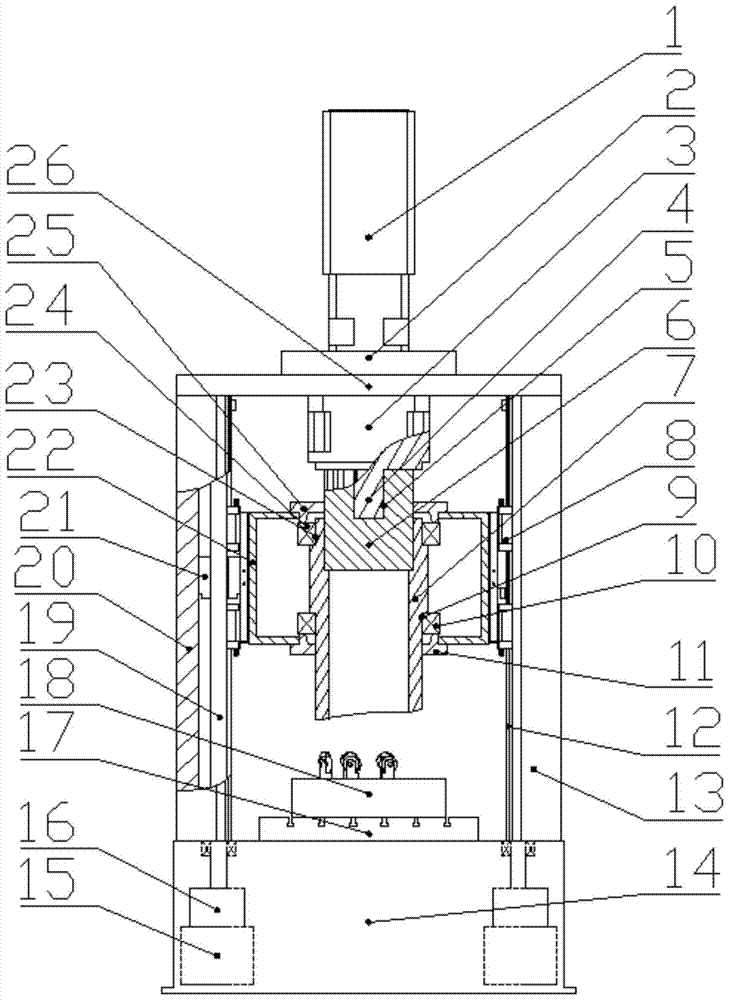

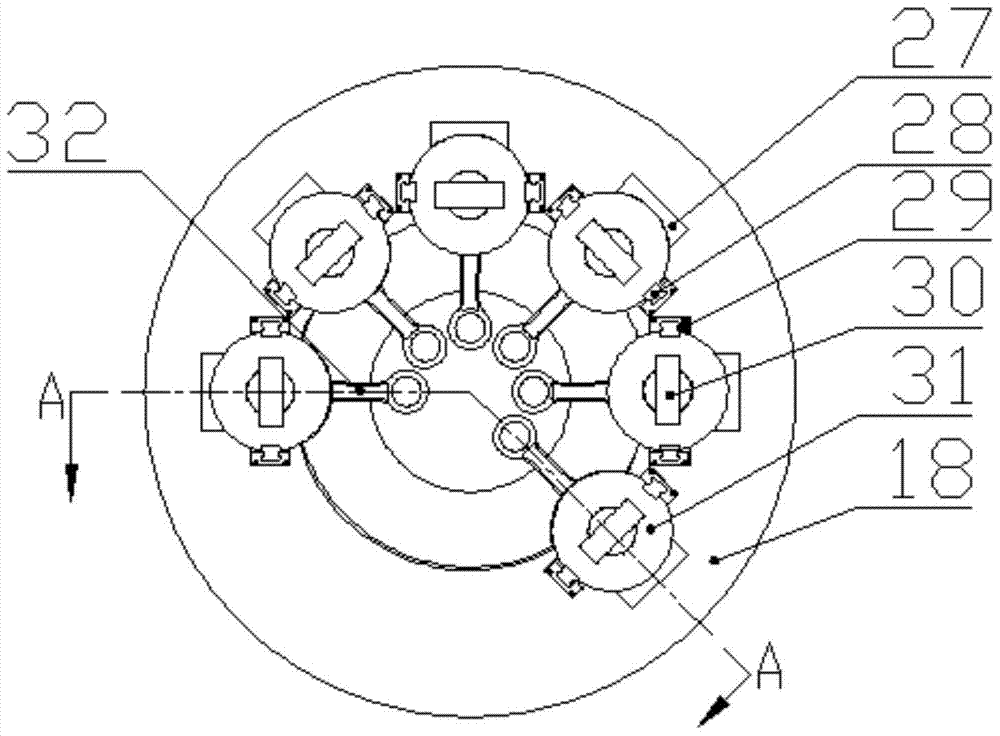

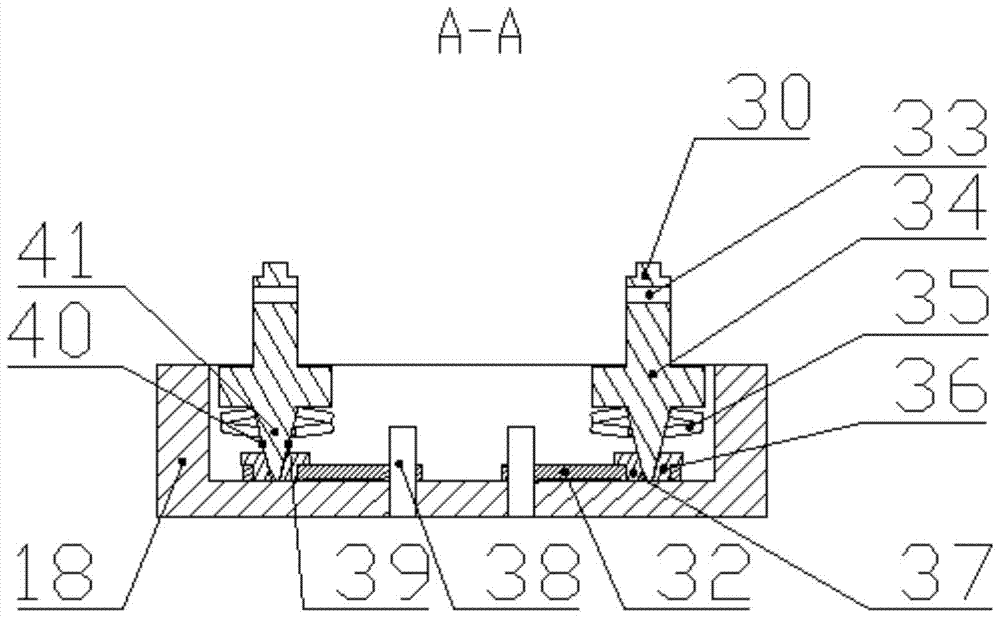

[0016] refer to figure 1 , figure 2 and image 3 , the low-cycle fatigue cracking equipment that the end face cam of the split connecting rod pushes the multi-spindle, including the base 14, the left and right sides of the base 14 are fixedly connected with the first column 20 and the second column 13, the first column 20, the second column The upper side of the two columns 13 is fixedly connected with a crossbeam 26, the motor deceleration power mechanism is connected on the crossbeam 26, the power output of the motor deceleration power mechanism is connected with the power input of the cam lifting mechanism, and the first slider 8 and the first slider 8 connected to the cam lifting mechanism both sides The inner side of the column 20 and the second column 13 is connected with the first guide rail 12 to cooperate. When working, the end face cam 7 of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com