A furniture board sander

A technology for sanding machines and plates, applied in the field of sanding machines, can solve problems such as waste of human resources, unfavorable workpiece grinding, and inability to improve efficiency, and achieve reasonable structural design, small occupied space, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

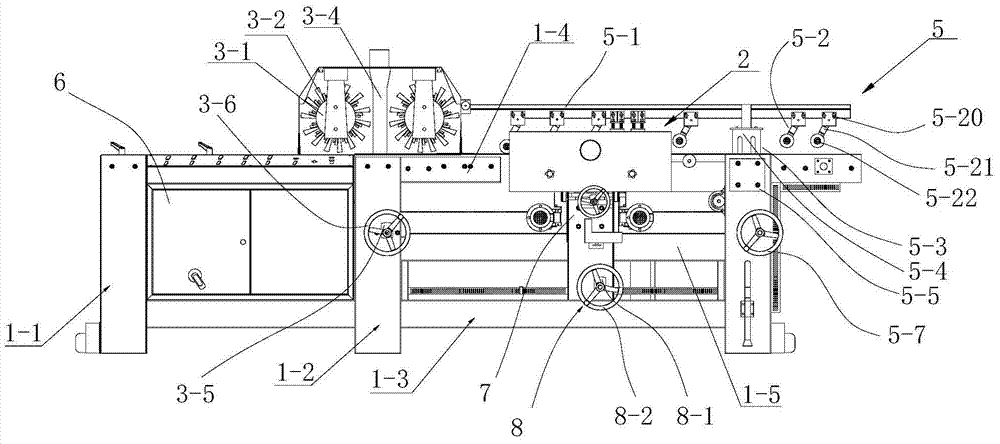

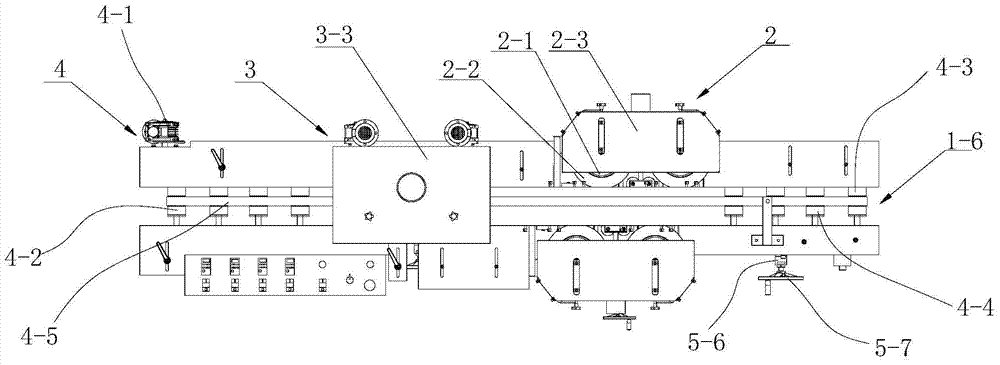

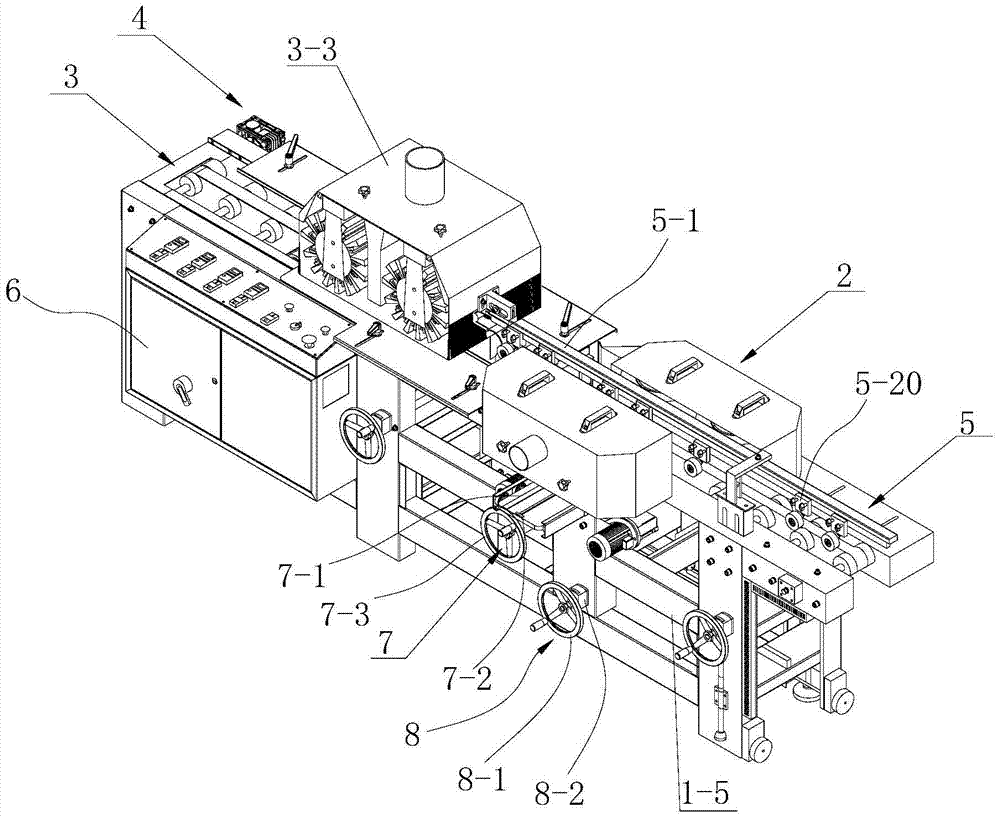

[0021] see Figure 1 to Figure 3 , A furniture board sanding machine, including a frame 1, a side sanding mechanism 2, an upper surface sanding mechanism 3, a board conveying mechanism 4, a board upper limit mechanism 5, and a control box 6.

[0022] Among them, the frame adopts a frame structure, including vertical beams 1-1 at both ends, several middle vertical beams 1-2, and lower beams 1-3 connecting the adjacent middle vertical beams, which are installed on the two end vertical beams and the middle vertical beam. The two upper beams 1-4 at the upper end and the end beams 1-5 connecting the vertical beams on the same side, the plate conveying channel 1-6 is formed between the above two upper beams, and the plate conveying mechanism 4 is arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com