Heat conduction pressing plate uniform in heat transfer and good in heat preservation effect

A heat equalization and platen technology, applied in the field of heat transfer platens, can solve the problems of uneven surface of the heat platen, unbalanced heat transfer, affecting the quality of the plate, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now in conjunction with accompanying drawing, the present invention is described in detail:

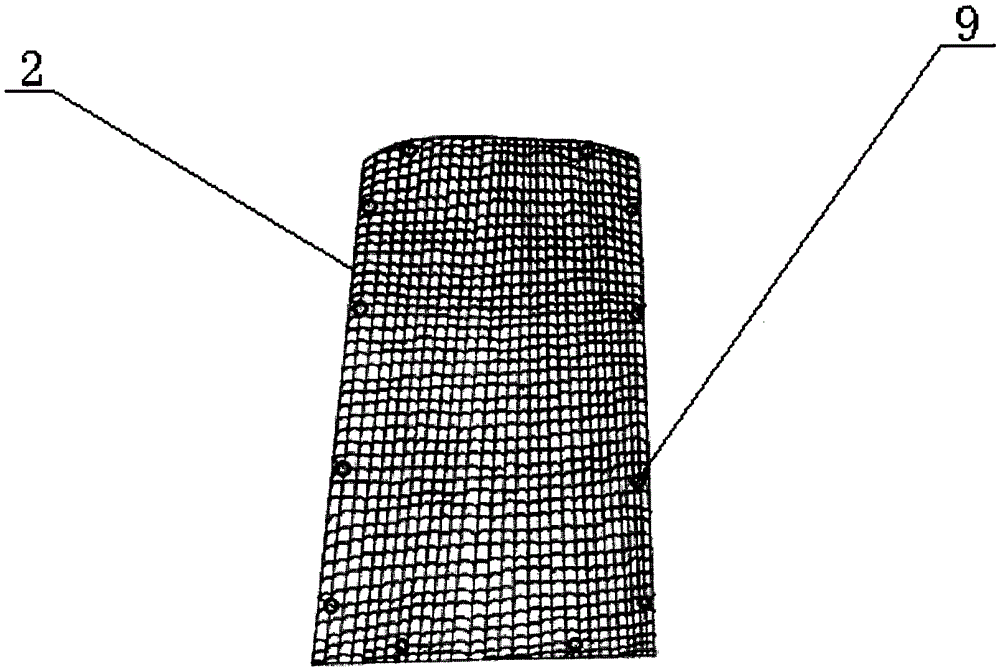

[0034] The present invention is made up of pressing bag frame (1), buffer pad one (2), stainless steel plate one (3), buffer pad two (4), stainless steel plate two (5), combined frame (6).

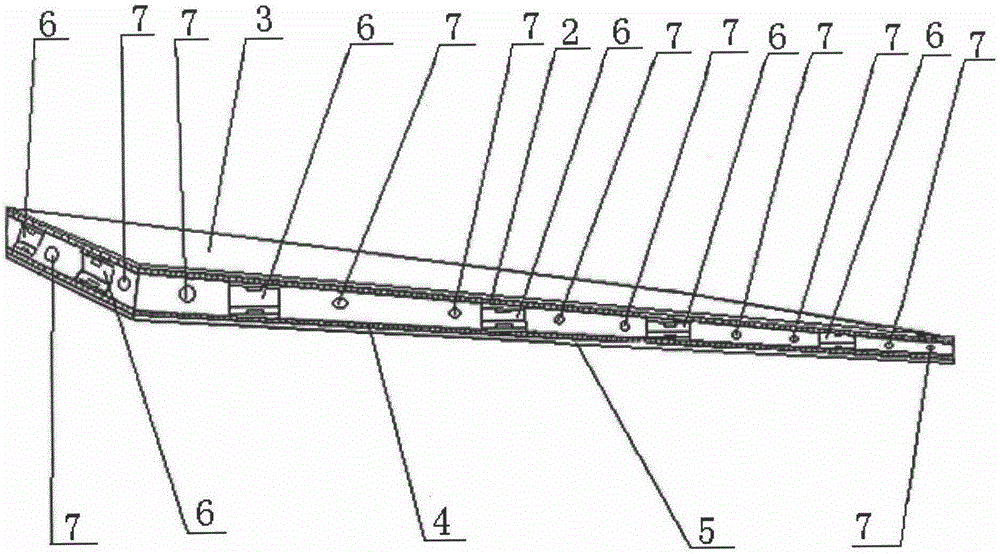

[0035] figure 1 Shown is the structural representation of the present invention. Among them, 2 is a cushion pad one (2), 3 is a stainless steel plate one (3), 4 is a cushion pad two (4), 5 is a stainless steel plate two (5), 6 is a combination frame (6), and 7 is a press Several heat circulation holes (7) that are provided with inside the bag frame.

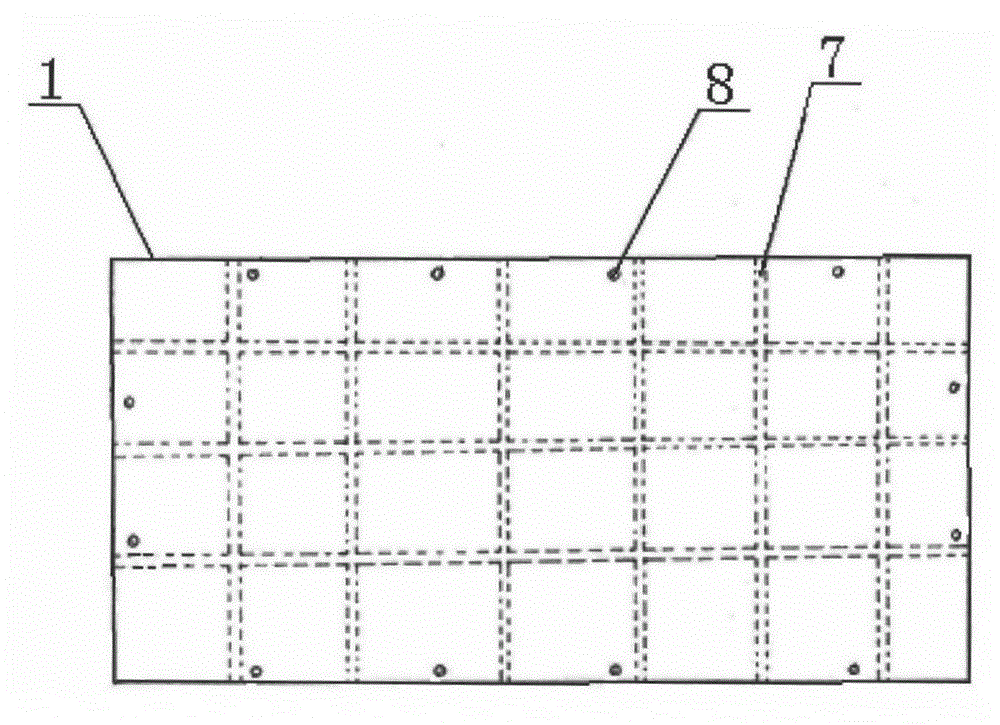

[0036] figure 2 Shown is a schematic structural view of the medium pressure bag frame (1) of the present invention. The bag holder (1) is a square plate, and several heat circulation holes (7) are arranged inside the bag holder (1), and twelve heat circulation holes (7) are respectively arranged along the upper and lower edges of the bag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com