Alumite leapfrog driving traction roller of gilding press

A technology of anodized aluminum and hot stamping machine, which is applied in the field of parts and components, can solve the problems of easy clogging of adsorption holes by dust, labor and time consuming, and affecting production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

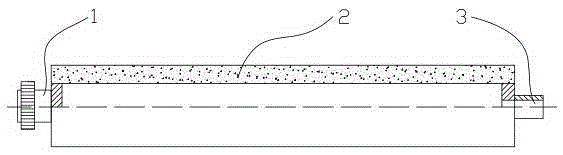

[0009] Such as figure 1 As shown, the anodized aluminum of the hot stamping machine jumps to drive the traction roller, which includes a roller 2 and a roller shaft 1 fixedly connected to both ends of the roller 2. One end of the roller 2 is closed, the other end is opened, and the roller 2 is opened. The end-connected roller shaft 1 is provided with an axial hole 3 connecting the inner cavity of the roller with the outside world, and the roller 2 is made of powder metallurgy porous material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com