Plugging machine

A technology for plugging machines and racks, which is applied in the directions of closing plugs, fixing plugs, and sealing with plugs. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

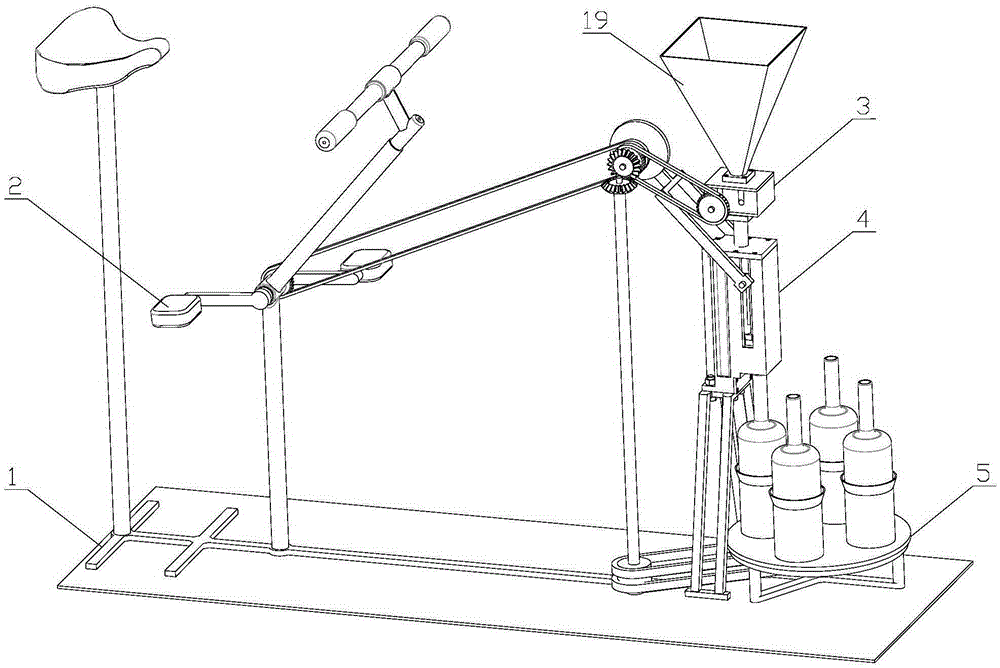

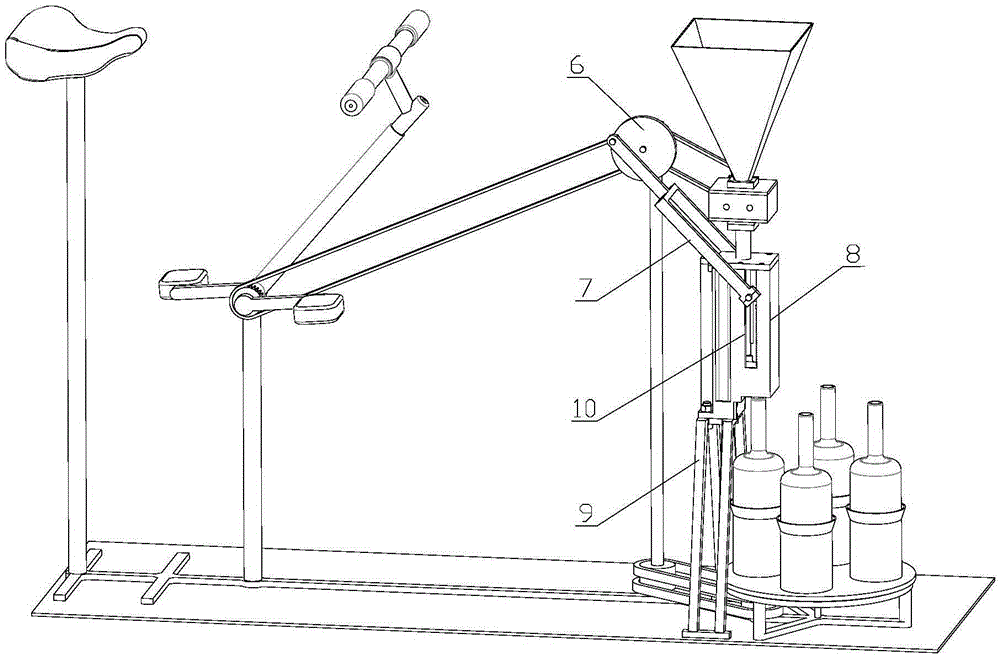

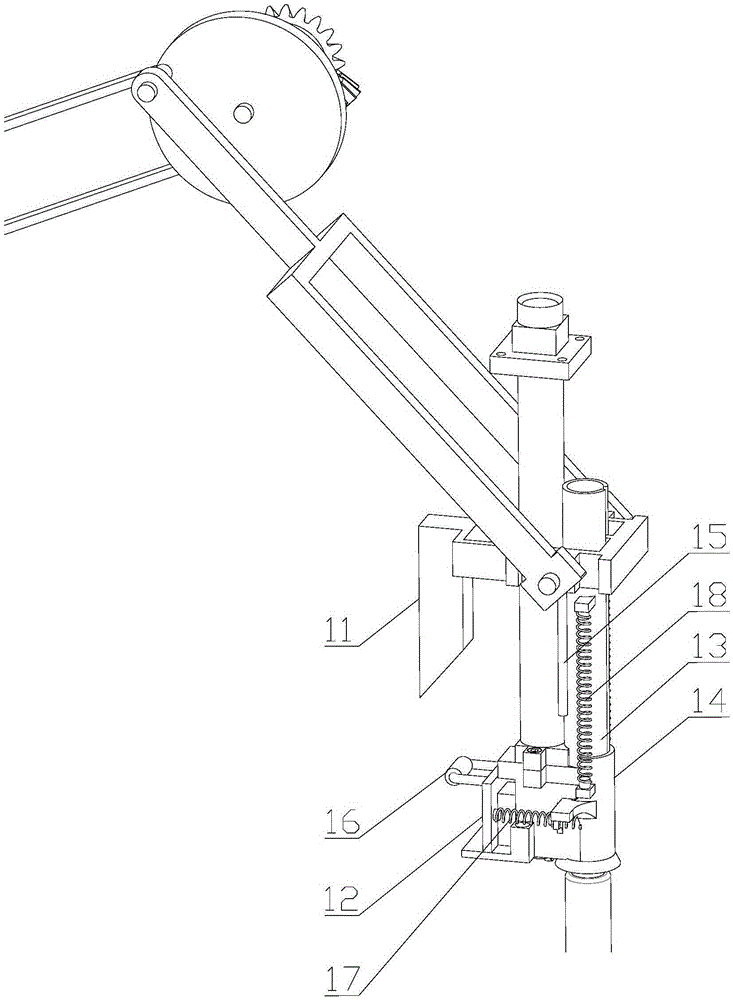

[0019] Embodiment 1 of the present invention: a corking machine, comprising a frame 1, a pedal 2, a plug unscrambling device 3, a corking device 4 and an intermittent indexing device 5, the pedal 2 is arranged on the frame 1, The intermittent indexing device 5 is arranged on the frame 1, the corking device 4 is arranged above the intermittent indexing device 5, the corking device 3 is arranged above the corking device 4, and the corking device 4 includes a runner 6, a connecting rod 7, The corking assembly 8 and the bracket 9, the runner 6 is eccentrically connected to one end of the connecting rod 7, the other end of the connecting rod 7 is hinged on the corking assembly 8, the corking assembly 8 is arranged on the bracket 9, and the bracket 9 is arranged on the frame 1, runner 6 is connected with pedal 2 by sprocket. The running wheel 6 is eccentrically connected to one end of the connecting rod 7 , which means that the position of the connecting shaft between the running wh...

Embodiment 2

[0025] Embodiment 2 of the present invention: a corking machine, comprising a frame 1, a pedal 2, a plug unscrambling device 3, a corking device 4 and an intermittent indexing device 5, the pedal 2 is arranged on the frame 1, The intermittent indexing device 5 is arranged on the frame 1, the corking device 4 is arranged above the intermittent indexing device 5, the corking device 3 is arranged above the corking device 4, and the corking device 4 includes a runner 6, a connecting rod 7, The corking assembly 8 and the bracket 9, the runner 6 is eccentrically connected to one end of the connecting rod 7, the other end of the connecting rod 7 is hinged on the corking assembly 8, the corking assembly 8 is arranged on the bracket 9, and the bracket 9 is arranged on the frame 1, runner 6 is connected with pedal 2 by sprocket. The running wheel 6 is eccentrically connected to one end of the connecting rod 7 , which means that the position of the connecting shaft between the running wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com