U-shaped plate combined assembled diversion pier structure

A combined assembly and diversion pier technology, which is applied in the direction of ship lifting devices, ship locks, buildings, etc., can solve the problems of affecting the use function, difficult to repair, and long construction period, so as to save project cost, ensure stability, and facilitate construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

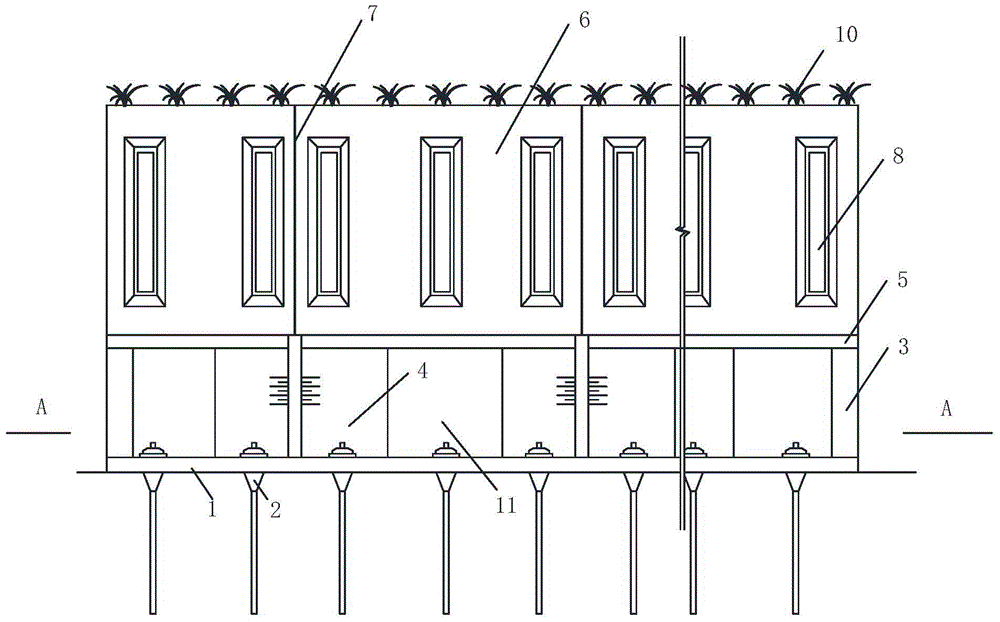

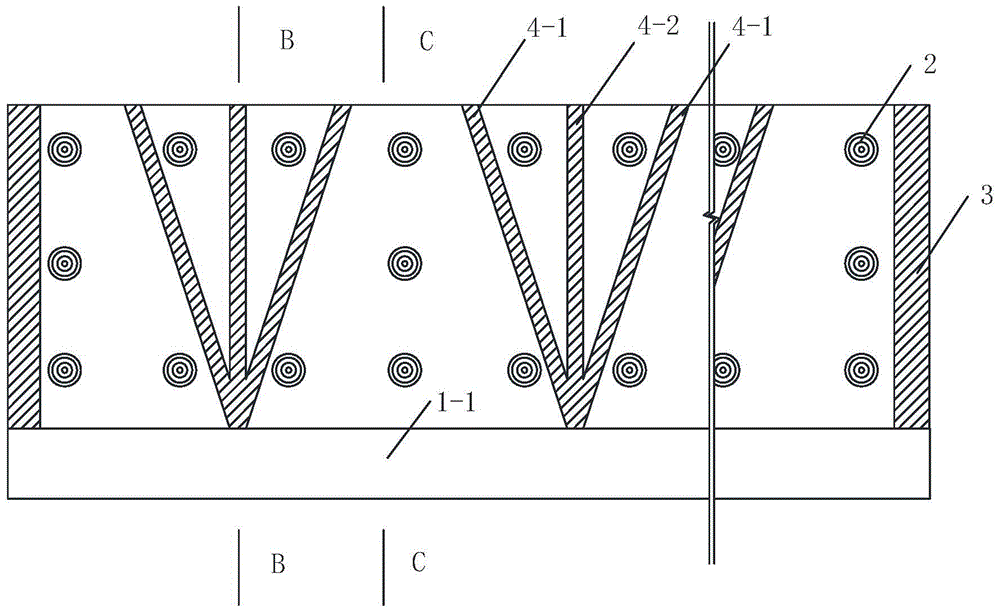

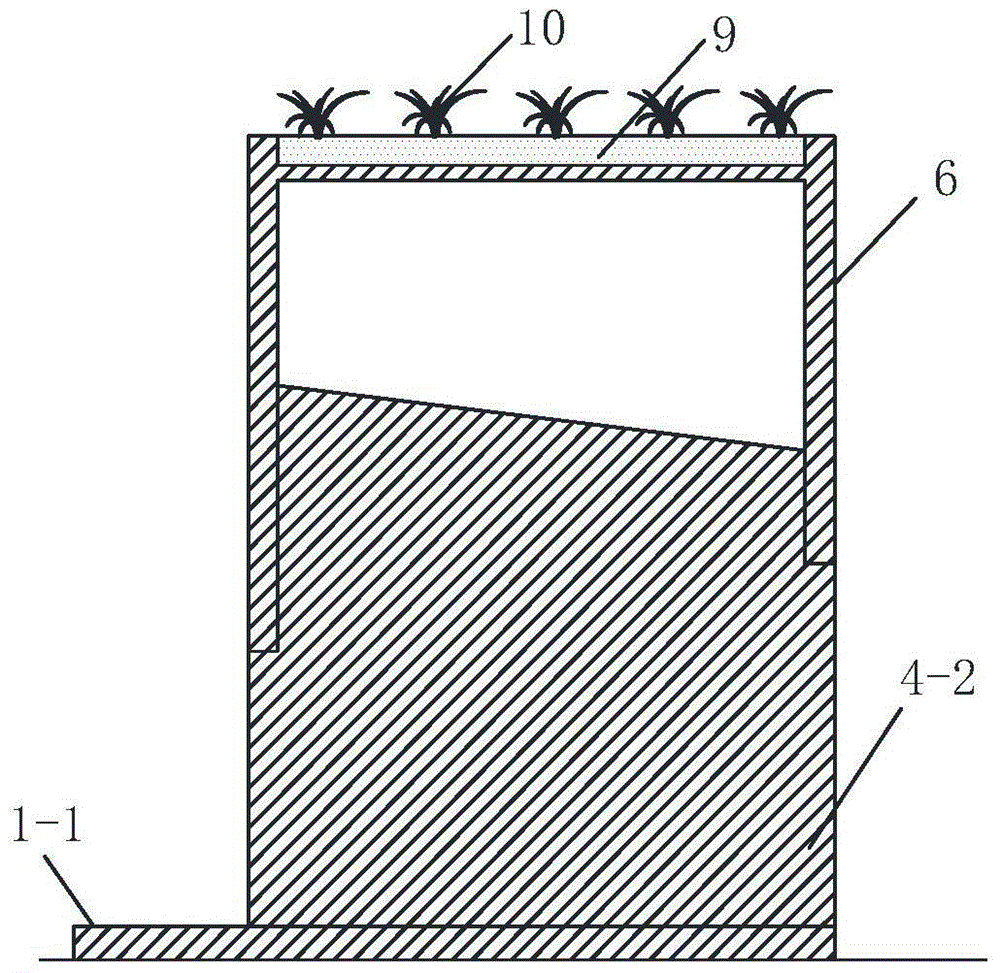

[0018] See Figure 1 ~ Figure 4 , a U-shaped plate combined assembly type diversion pier structure, including a prefabricated bottom plate 1 fixed on the river bed, a prefabricated load-bearing wall 3 is respectively fixed on the upstream and downstream ends of the prefabricated bottom plate 1; A plurality of evenly distributed prefabricated diversion walls 4 are arranged between the walls 3, and the prefabricated diversion walls 4 are fixed on the prefabricated bottom plate 1, and the horizontal projection of the prefabricated diversion walls 4 is a trisecting claw-shaped structure , there are two side wing walls 4-1 and a middle main wall 4-2, and the finger end of the prefabricated flow diversion wall 4 is its channel end, and the claw roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com