Method for constructing recycled mixed concrete beams and slabs

A construction method and concrete technology, which is applied in the direction of floors, joists, girders, etc., can solve the problems of difficult cutting of recycled aggregates and long construction period, and achieve the effects of saving electric energy, improving production efficiency, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

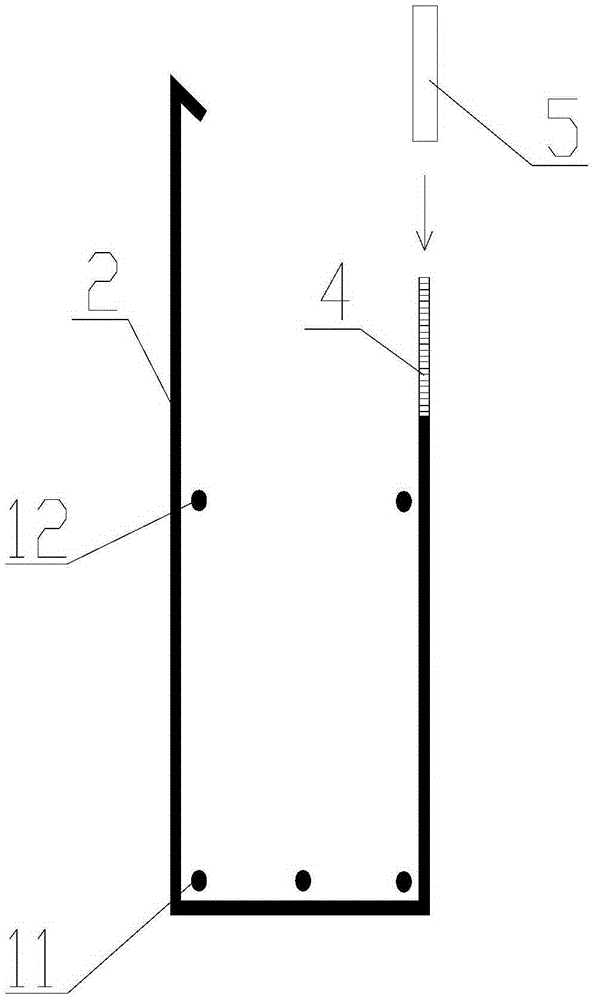

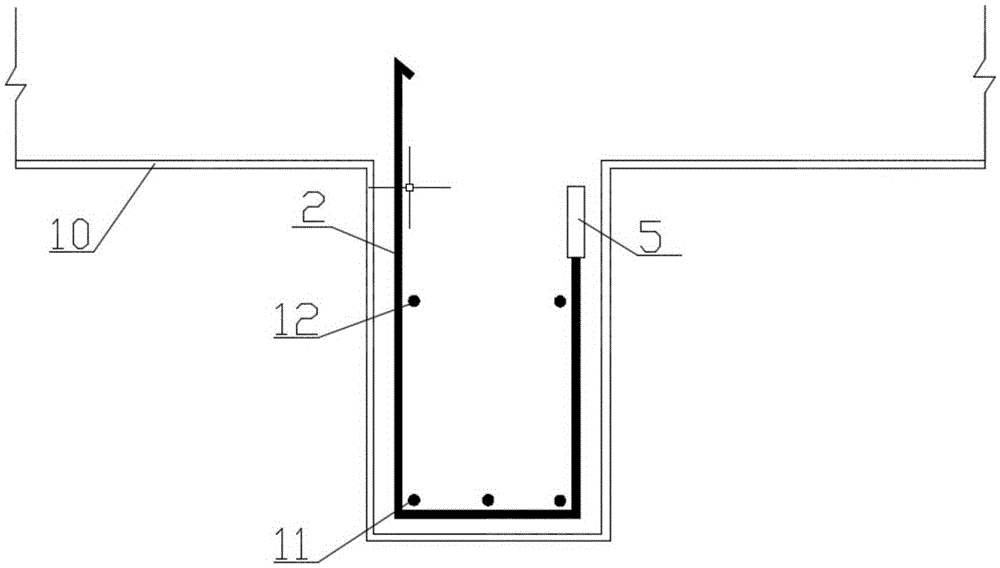

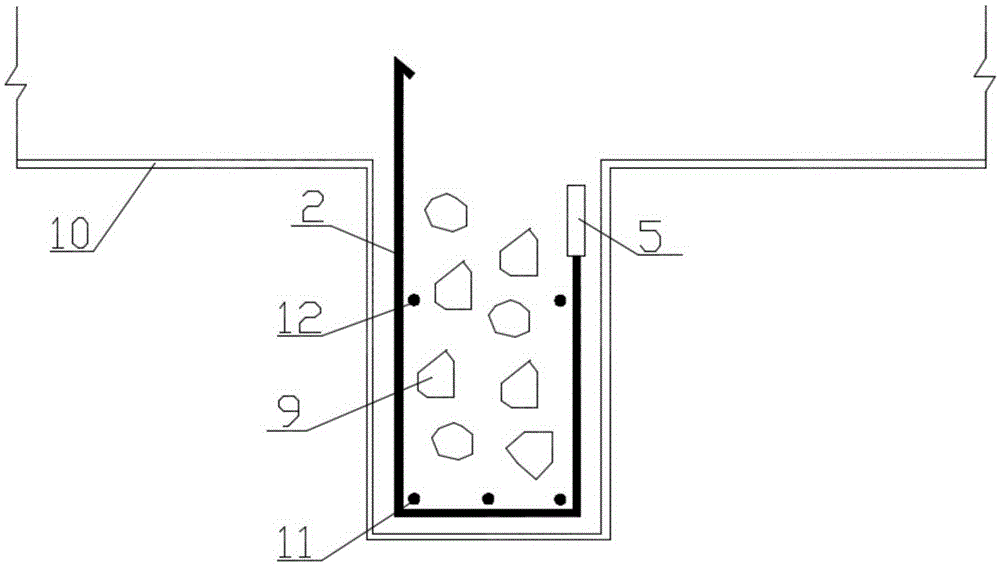

[0034] see Figure 1-7 As shown, the construction method of the recycled mixed concrete beam slab of the present invention includes: dividing the installation of conventional beam slab steel bars into two installations, first installing the bottom steel bars; then placing waste concrete blocks, then installing the upper steel bars, and finally pouring new concrete to complete. The beam slab is placed on the template 10, and waste concrete aggregates 9 are placed in the beam slab.

[0035] Among them, the stirrups of the beam are made into the upper L-shaped stirrup 1 and the lower L-shaped stirrup 2, and are installed twice. The installation connection point is set at the upper 2 / 3L of the bottom of the stirrup, and the plate reinforcement is made of cold-rolled steel. The overall hoisting of the mesh. Both the upper and lower sections of the L-shaped hoop connecting joint are provided with straight thread sleeve threads, and the two sections of thread threads can rotate bidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com