Multifunctional fuel energy-saving hot-water steam boiler

A hot water steam, multi-functional technology, applied in steam boilers, steam generation, water heaters, etc., can solve the problems of not being suitable for new fuels, etc., and achieve the effect of saving labor and trouble in operation, and the size is random

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

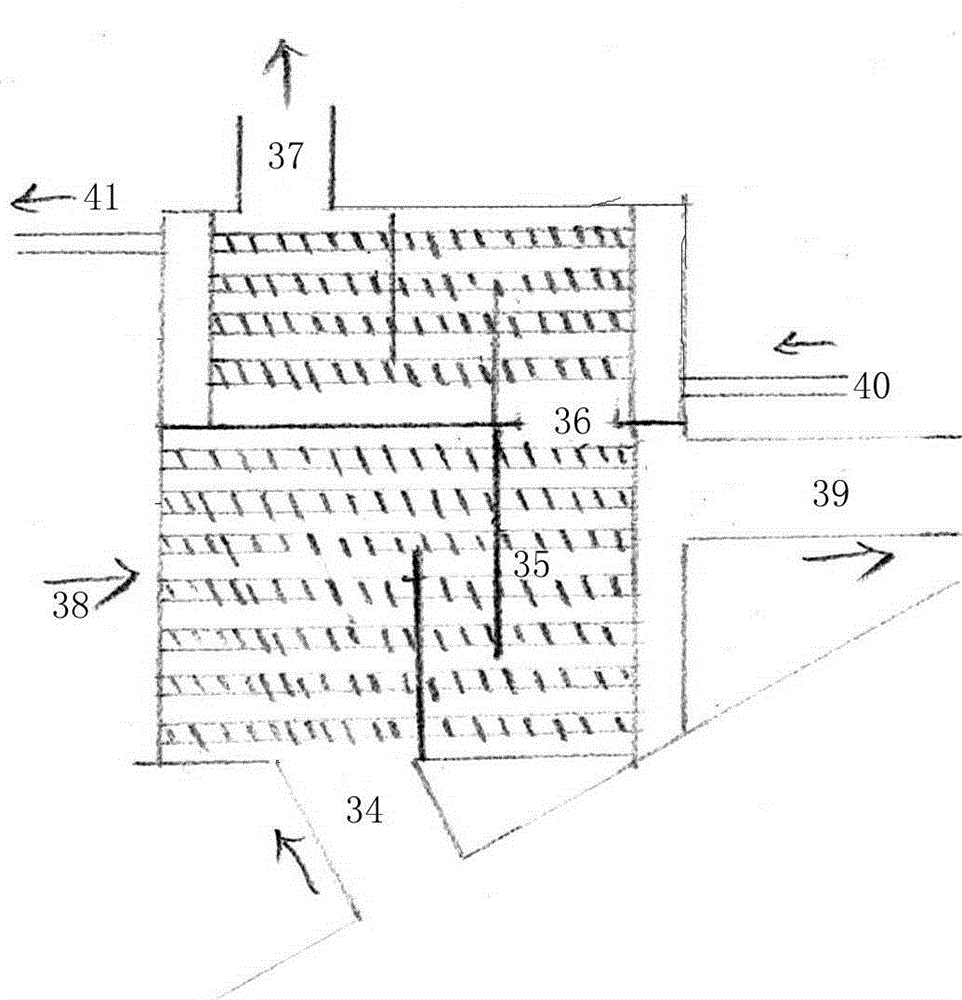

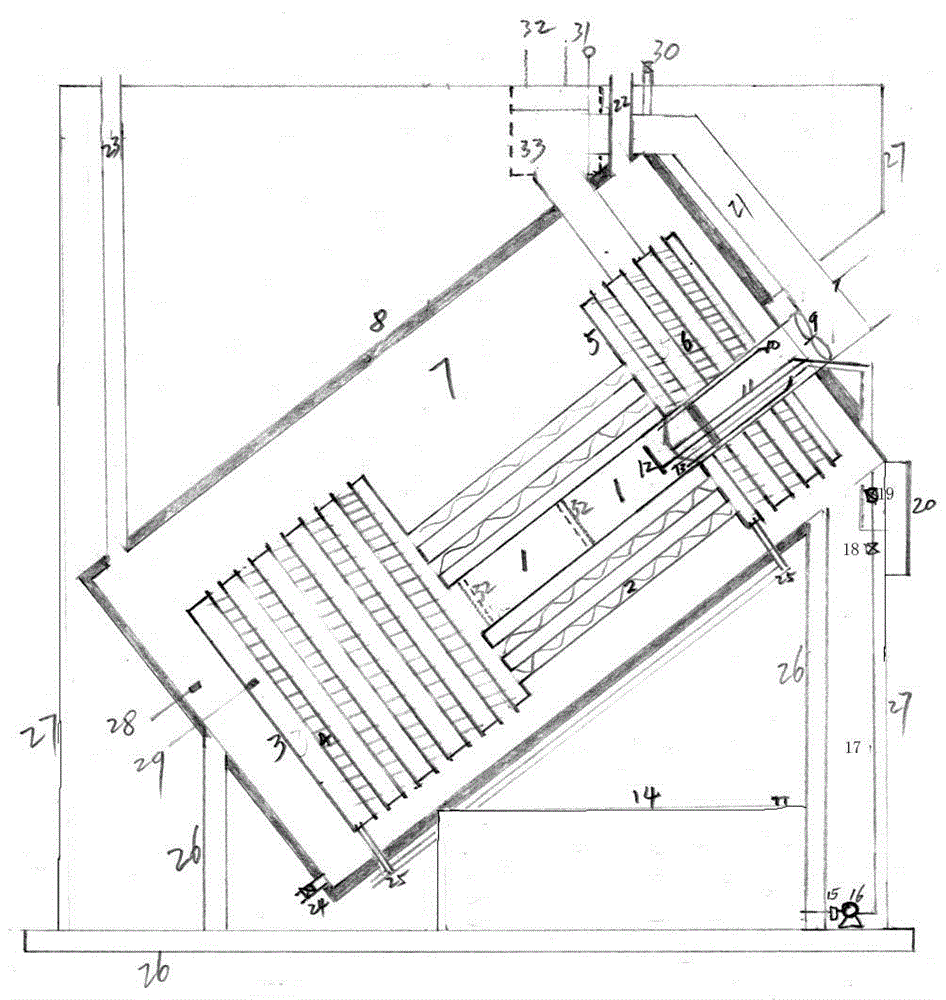

[0014] like figure 1 As shown, a multi-functional fuel-saving hot water steam boiler includes a bracket 26, on which a furnace body 8 is arranged obliquely, the bracket 26 and the furnace body 8 are all arranged in a shell 27, and a furnace 1. Water chamber 7, primary heat exchange chamber 3 and secondary heat exchange chamber 5. Water chamber 7 is provided with water inlet 23, water return port 22, condensed water outlet 25 and sewage outlet 24. The heat chamber 3 is connected, the primary heat exchange chamber 3 is provided with a heat exchange pipe I4, the primary heat exchange chamber 3 is connected with the secondary heat exchange chamber 5 through the air return pipe 2, and the secondary heat exchange chamber 5 is provided with a heat exchanger The heat pipe 14, the secondary heat exchange chamber 5 is connected with the air preheating chamber 33; the inside of the furnace 1 is provided with a number of combustion enhancing baffles 32, the inlet end of the furnace 1 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com