Prediction method for corrosion residual life of transmission line towers at industrial area

A life prediction and transmission line technology, applied in the field of electric power engineering, to achieve the effect of ensuring safety, high accuracy, and preventing disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

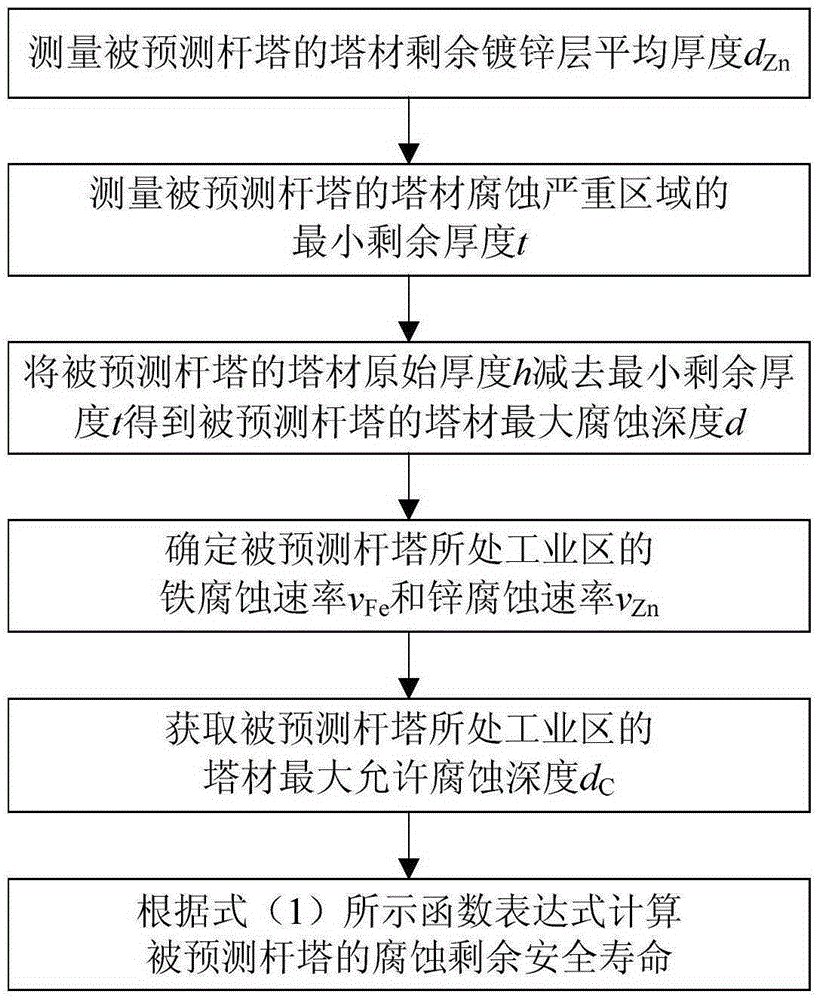

[0034] Such as figure 1 As shown, the steps of the method for predicting the remaining life of corrosion of transmission line towers in industrial areas in this embodiment include:

[0035] 1) Measure the average thickness d of the remaining galvanized layer of the tower material to be predicted Zn ; In this embodiment, the surface of the tower has been covered with red rust, so the average thickness d of the remaining galvanized layer of the tower is predicted Zn = 0;

[0036] 2) Measure the minimum remaining thickness t of the severely corroded area of the tower material of the predicted tower, and subtract the minimum remaining thickness t from the original thickness h of the tower material of the predicted tower to obtain the maximum corrosion depth d of the tower material of the predicted tower; in this embodiment , the original thickness h of the tower material is predicted to be 10mm, and the minimum remaining thickness t is 9mm, so the maximum corrosion depth d of ...

Embodiment 2

[0057] This embodiment is basically the same as Embodiment 1, and the main difference is that the implementation of step 3) is different.

[0058] In this embodiment, the detailed steps of step 3) include: first obtain the classification of the corrosion environment of the industrial area where the predicted tower is located, and then query the preset corrosion environment maximum corrosion rate comparison table (see Table 1) according to the classification of the corrosion environment to obtain The iron corrosion rate v of the industrial area where the predicted tower is located Fe and zinc corrosion rate v Zn .

[0059] Table 1: Comparison table of maximum corrosion rate in corrosive environment.

[0060]

[0061] The corrosion environment classification of the industrial area where the predicted tower is located can be obtained from the environmental monitoring center or atmospheric corrosion site where the predicted tower target is located. According to the provision...

Embodiment 3

[0064] This embodiment is basically the same as Embodiment 1, and the main difference is that the implementation of step 3) is different.

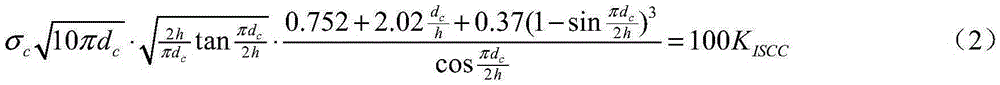

[0065] In this embodiment, the detailed steps of step 3) include: first directly calculate the iron corrosion rate v of the industrial area where the tower is located according to formula (3) Fe , and then according to the predicted iron corrosion rate v of the industrial area where the tower is located Fe Find the maximum corrosion rate comparison table of the preset corrosive environment (see Table 1), and obtain the zinc corrosion rate v of the industrial area where the predicted tower is located Zn ;

[0066] v Fe =1000(h-t)÷T(3)

[0067] In formula (3), v Fe is the iron corrosion rate in the industrial area where the predicted tower is located, h is the original thickness of the tower material of the predicted tower, t is the minimum remaining thickness of the severely corroded area of the tower material of the predicted tower, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com