Method for controlling flue gas of coal-fired boiler

A technology for coal-fired boilers and control methods, which is applied in separation methods, chemical instruments and methods, and multiple fluid ratio control, etc., can solve problems such as desulfurization system equipment and slurry pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

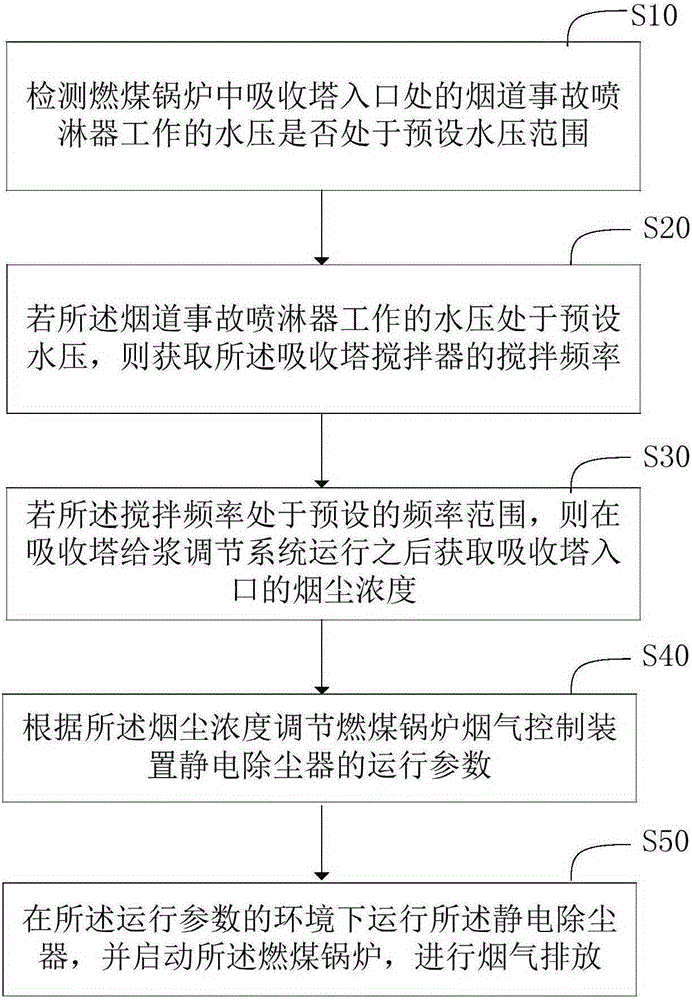

[0012] The specific implementation of the method for controlling flue gas of a coal-fired boiler provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] refer to figure 1 , figure 1 Shown is a flow chart of a coal-fired boiler flue gas control method of an embodiment, including the following steps:

[0014] S10, detecting whether the working water pressure of the flue accident sprinkler at the entrance of the absorption tower in the coal-fired boiler is within the preset water pressure range;

[0015] In the above step S10, in the coal-fired boiler desulfurization system with a bypass, the desulfurization bypass is always turned on when the boiler is ignited to separate the desulfurization system. After the boiler starts up and enters the normal combustion state, after the electrostatic precipitator is put into operation, the bypass baffle is closed, and the desulfurization inlet bypass baffle is opened to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com