Method for replacing primary hydrogenation catalyst in device for preparing methanol by coke oven gas

A technology for hydrogenation catalysts and coke oven gas, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the irreversible poisoning of methanol synthesis catalysts and reduce the start-up of devices efficiency, long shutdown time, etc., to achieve good organic sulfur conversion efficiency, increase device operating rate, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

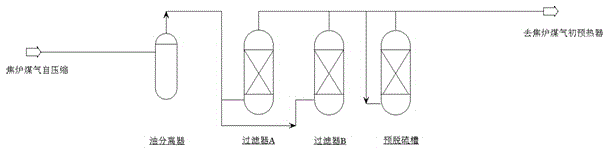

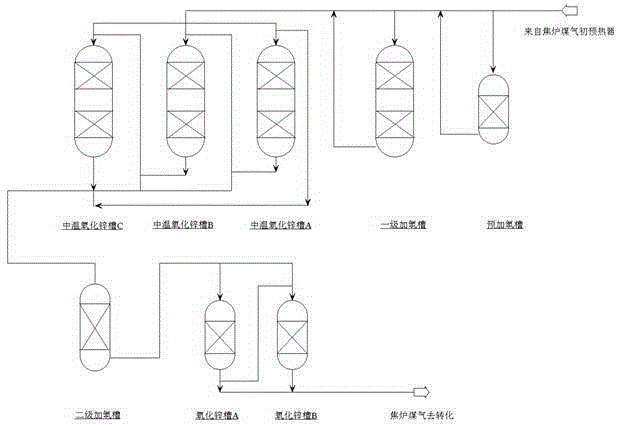

[0020] Embodiment: Taking this method as an example in a 200,000-ton / year coke oven gas methanol system, the filling capacity of the pre-hydrogenation tank is 5m 3 , the gas volume is 30000NM 3 / h, so the airspeed is 6000NM 3 / (h·m 3 ), the organic sulfur conversion rate of the hydrogenation catalyst is about 60% at this space velocity. The organic sulfur loading capacity of the iron-manganese desulfurization catalyst is 52m 3 , the conversion rate of organic sulfur is 80%. The upper part of the zinc oxide tank A is equipped with 5m 3 , so the organic sulfur conversion rate is also 60%. The filling capacity of the secondary hydrogenation tank is 17m 3 , the gas volume is 30000NM 3 / h, so the airspeed is 1768NM 3 / (h·m 3 ), the organic sulfur conversion rate of hydrogenation catalyst under this space velocity is 90%. The organic sulfur content in the fine desulfurization inlet gas is about 150mg / m3 3 , after cutting out the first-level hydrogenation catalyst, use the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com