Method and apparatus for controlling voltage of flying capacitor in multilevel inverter circuit

A technology of multi-level inverter and floating capacitor, which is applied in output power conversion devices, electrical components, and the conversion of AC power input to DC power output, etc., can solve the problem of increasing switch tube stress and inconvenient switch tube selection. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

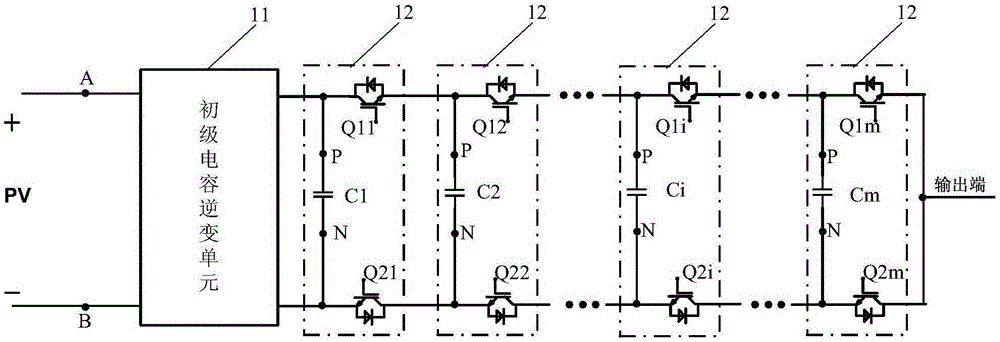

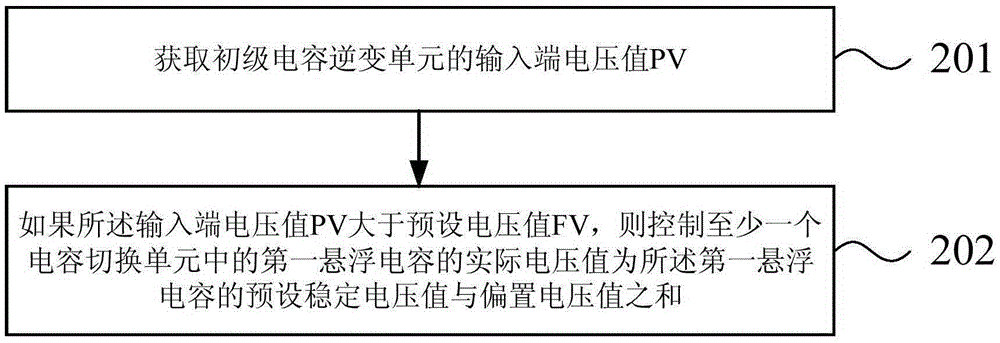

[0036] figure 2 It is a flowchart of a method for controlling the floating capacitor voltage in a multi-level inverter circuit provided by Embodiment 1 of the present invention. This embodiment is applicable to controlling the dynamic adjustment of the floating capacitor voltage in a multi-level inverter circuit , the method can be performed by a device for controlling the floating capacitor voltage in a multilevel inverter circuit, such as figure 2 As shown, this embodiment provides a method for controlling the floating capacitor voltage in a multi-level inverter circuit. The structure of the multi-level inverter circuit can be as follows figure 1 As shown, the method includes the following steps:

[0037] Step 201 , acquiring the input terminal voltage value PV of the primary capacitor inverter unit 11 .

[0038]In this embodiment, the multilevel inverter circuit includes a primary capacitor inverter unit 11 and cascaded m level switch units 12, the input end of the prim...

Embodiment 2

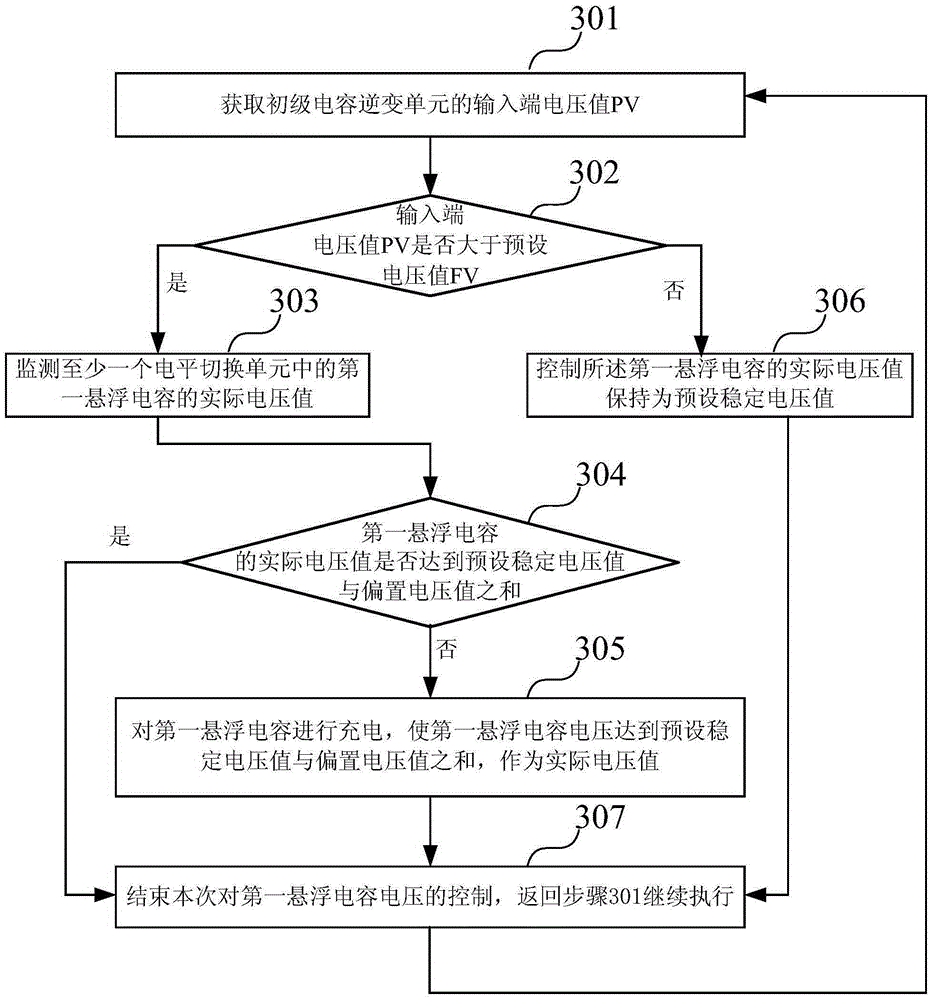

[0051] image 3 It is a flowchart of a method for controlling the floating capacitor voltage in a multi-level inverter circuit provided by Embodiment 2 of the present invention. This embodiment is optimized on the basis of the above-mentioned embodiments. In this embodiment, the steps Controlling the actual voltage value of the first floating capacitor in at least one level switching unit is the sum of the preset stable voltage value and the bias voltage value of the first floating capacitor, which is further optimized to: monitor the at least one level switching The actual voltage value of the first floating capacitor in the unit; if the actual voltage value of the first floating capacitor in the jth level switching unit is lower than the sum of the preset stable voltage value and the bias voltage value, then for the first The floating capacitor is charged so that the actual voltage value reaches the sum of the preset stable voltage value and the bias voltage value.

[0052]...

Embodiment 3

[0074] A method for controlling the floating capacitor voltage in a multilevel inverter circuit provided by the present invention is specifically implemented in a multilevel inverter, by figure 1 It can be seen from the structural schematic diagram of the multilevel inverter circuit that the multilevel inverter includes a primary capacitor inverter unit 11 and m level switching units 12 connected in cascade. Among them, the primary capacitor inverter unit 11 has more implementation structures. Embodiment 3 of the present invention provides several implementations of the primary capacitor inverter unit, which may specifically be Figure 4A , Figure 4B , Figure 4C , Figure 4D , which are only circuit diagrams of four preferred primary capacitor inverter units 11 provided in Embodiment 3 of the present invention.

[0075] see Figure 4A As shown, the primary capacitor inverter unit 11 includes: a second capacitor C00, a third capacitor C01, a third switching tube Q1, a fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com