Method for machining precision camshaft

A processing method and camshaft technology, which are applied to metal processing equipment, workpieces, manufacturing tools, etc., can solve the problem that the camshaft cannot meet the roughness requirements, and achieve the effect of avoiding complicated programming process, satisfying processing accuracy and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

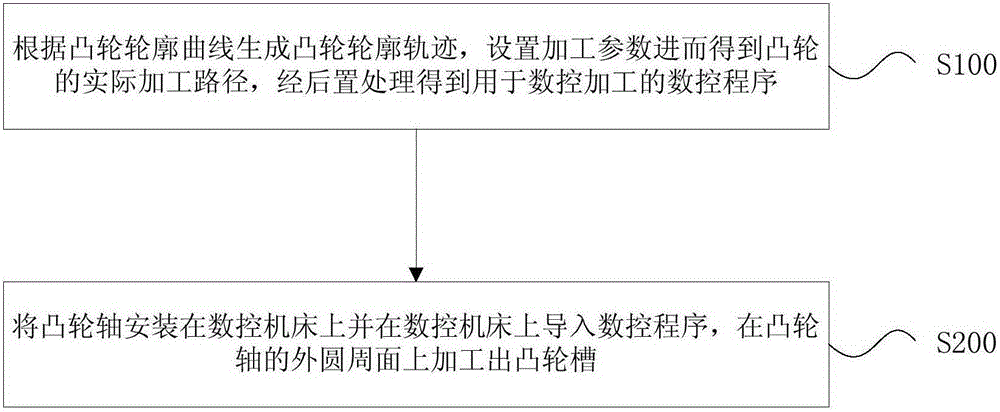

[0024] The precision camshaft machining method of the present invention optimizes the numerical control program for numerical control machining, improves the machining process route and adjusts the numerical control tool, so that the camshaft meets the requirements of profile and roughness, and solves the phenomenon of chatter marks on the surface of the camshaft. refer to figure 1 , a preferred embodiment of the present invention provides a precision camshaft machining method, comprising:

[0025] Step S100, generating the cam profile track according to the cam profile curve, setting the processing parameters to obtain the actual processing path of the cam, and obtaining the NC program for NC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com