Multi-hole multi-angle drilling clamp

A multi-angle, fixture technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of long assembly turnover cycle, unstable assembly fixture, slow production progress, etc., to improve processing efficiency and product qualification efficiency, reduce fixture turnover and preparation time, solve practical problems and improve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

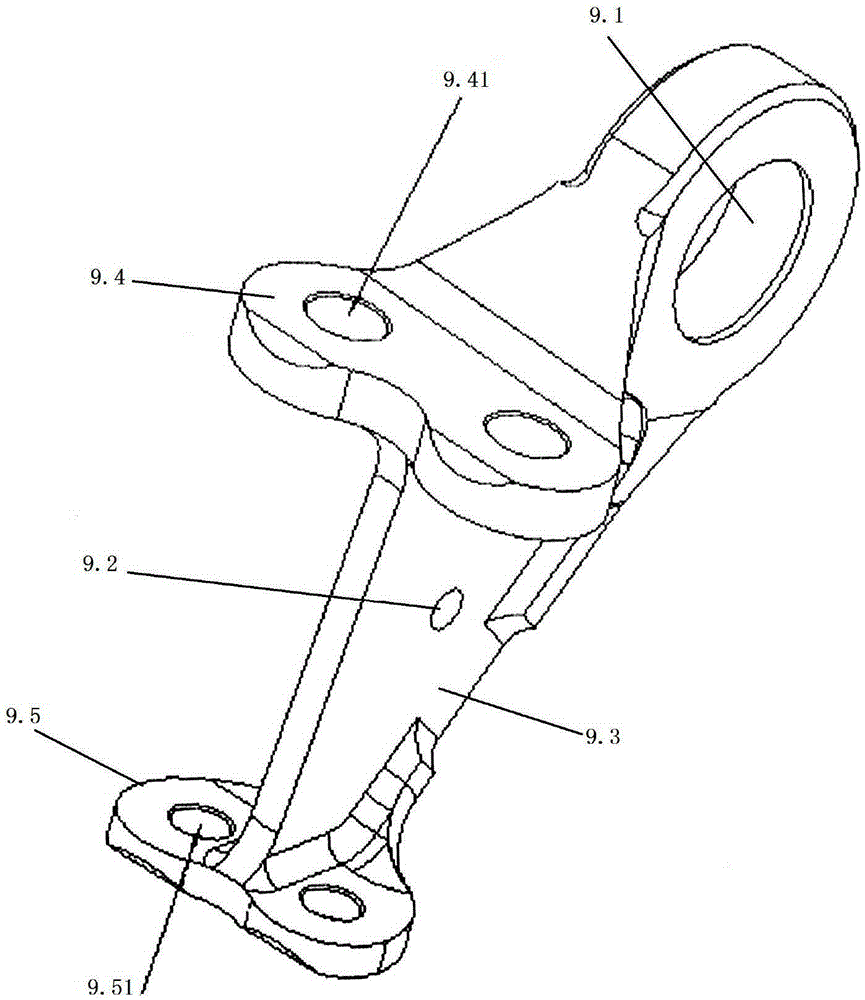

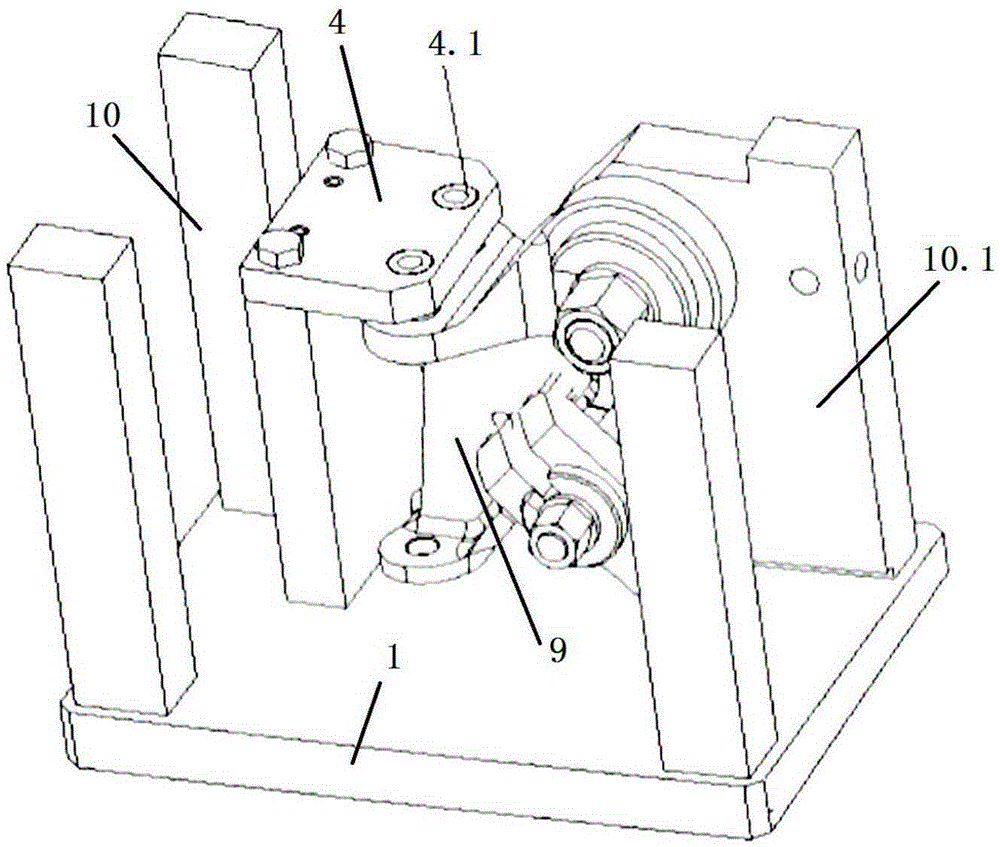

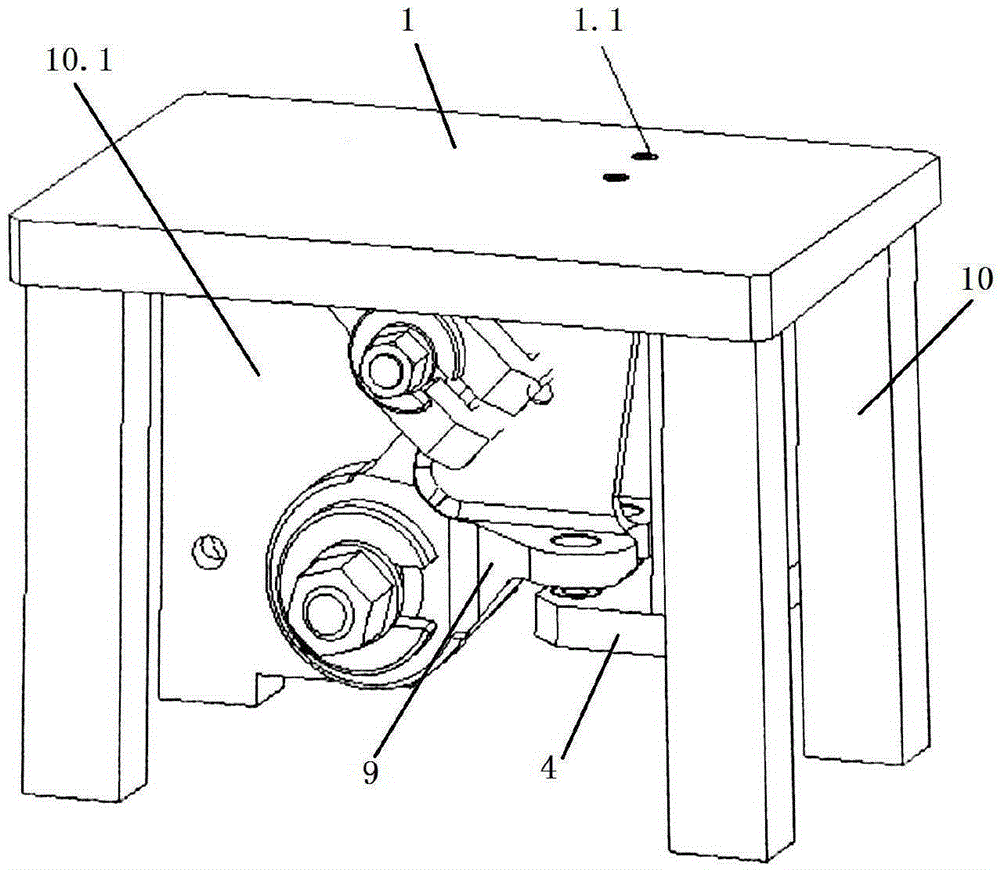

[0024] Such as Figure 1-5 As shown, a multi-hole multi-angle drilling fixture is used to clamp a part 9 with a hole in a spatial position. The part 9 has a mounting part I9.4 and a mounting part II9.5, and a mounting part I9.4 and a mounting part Ⅱ9.5 is arranged up and down on the part 9, the installation part I9.4 has a hole to be processed I9.41, the installation part II9.5 has a hole to be processed II9.51, and the processing fixture has a base 1, There are four pillars 10 around the base 1, a support block 11 is provided in the middle of the base 1, and a drill formwork 4 is provided on the support block 11. The installation part I9.4 and the installation part II9.5 are located between the base 1 and the drill formwork 4 Between, the lower surface of the drilling template 4 is parallel to the upper surface of the installation part I, and the drilling template 4 has a through hole I4.1 that matches the hole I9.41 to be processed; the upper surface of the base 1 and the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com