Feed system of top suspension centrifuge

A feeding system and centrifuge technology, applied in the direction of centrifuges, etc., can solve the problems that the massecuite distribution plate does not play a uniform distribution function, the screen basket swings, and the speed varies, so as to avoid unstable operation and improve production. Efficiency and the effect of ensuring production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

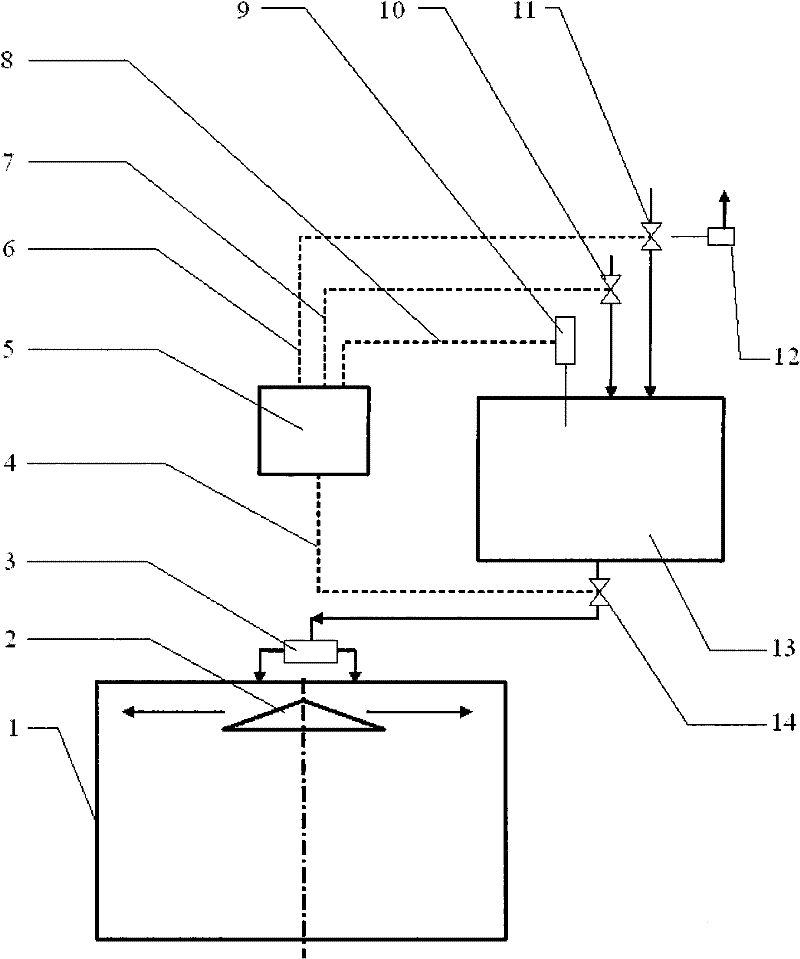

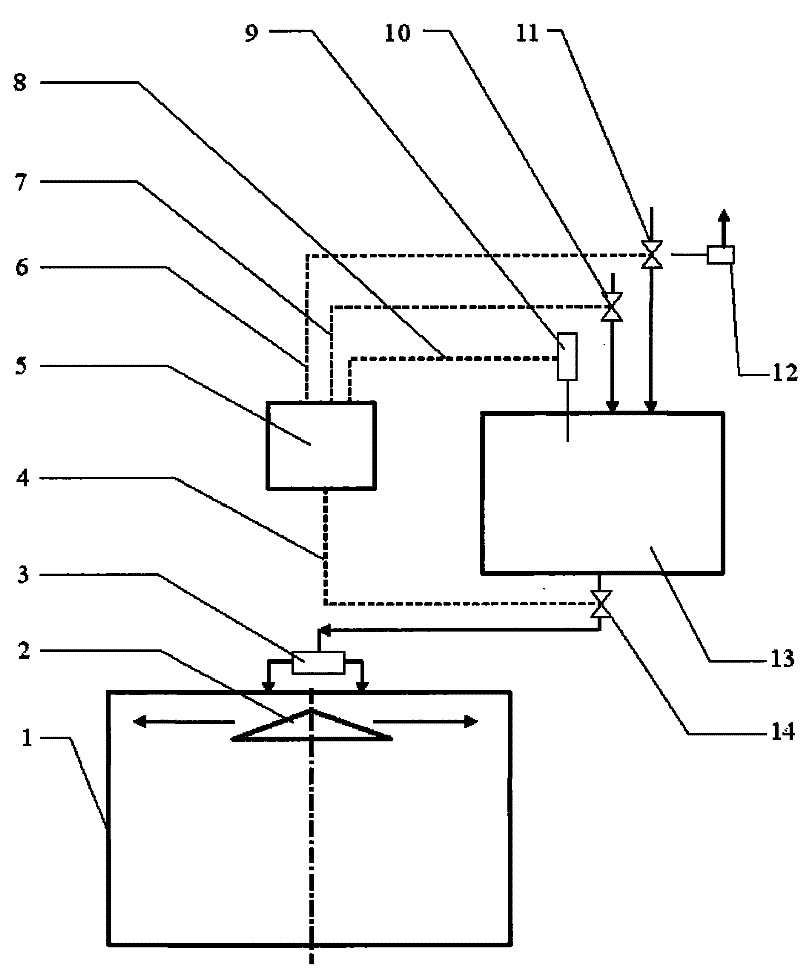

[0019] Such as figure 1 As shown, the top suspension centrifuge feeding system of the present invention is mainly made up of feeding tank 13 and massecuite distributing mechanism 3; It is 1.5 tons; the feeding tank 13 is provided with a material level detector 9; one end of the feeding tank 13 is connected with the massecuite distribution tank through the feeding valve 10, and the other end is connected with the massecuite distribution mechanism 3 through the discharge valve 14; The distributing mechanism 3 is installed on the cover plate of the centrifuge (not shown). The massecuite distributing mechanism 3 is a ring structure, and the drive shaft of the centrifuge passes through in the middle. Cloth opening (not shown); the top of the feeding tank 13 is connected to the compressed air pipeline through the compressed air three-way valve 11, and the other end of the three-way valve 11 is connected to the muffler 12.

[0020] The feeding system is controlled by the control mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com