Error compensation method for rotary shafts of double-rotary-table five-shaft linkage machine tool

A five-axis linkage machine tool, error compensation technology, applied in manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as the position offset of the small ball at the spindle end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described in detail below in conjunction with the accompanying drawings. The given embodiments are only used to illustrate specific implementation and beneficial effects, and are not intended to limit the protection scope of the present invention.

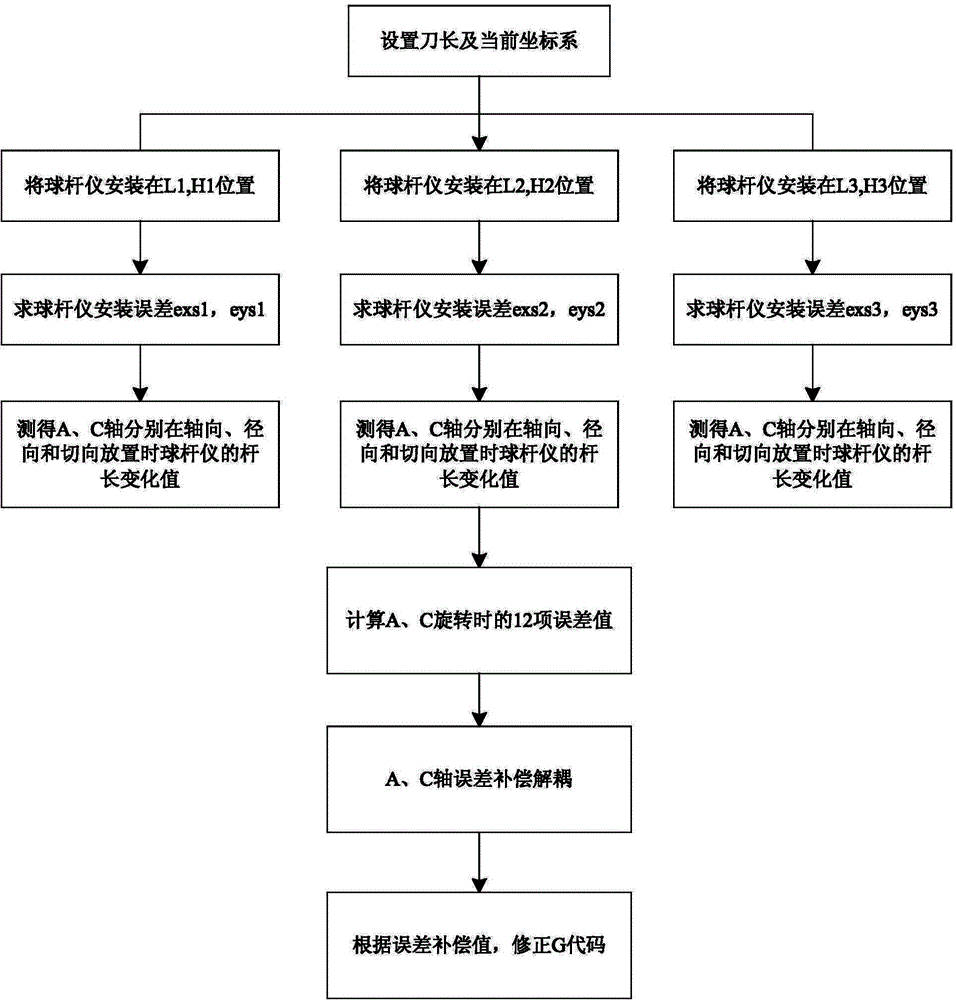

[0072] like figure 1 As shown, a method for error compensation of the rotary axis of a double turntable five-axis linkage machine tool, which includes the following steps:

[0073] (1) Set tool length and current coordinate system:

[0074] Use a tool setting instrument to measure the value of "knife handle length + length of small ball adsorption rod + standard small ball radius", set the length of T1 knife as this value, and use T1 knife when detecting errors.

[0075] According to the machine tool assembly relationship (RTCP parameter), set the X, Y, and Z values of the current coordinate system (such as G58) to the values of the C-axis rotation center in the A-axis coordinate sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com