Anti-caking method for powder ash pot

An anti-caking and ash tank technology, which is applied in the direction of containers, packaging, transportation and packaging, etc., can solve the problems of blowing, manual labor, and the inability of the materials in the ash tank to be transported to the mixing place, so as to prevent agglomeration, The effect of increasing mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

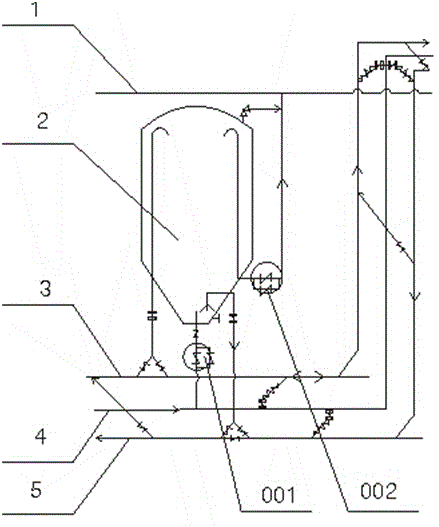

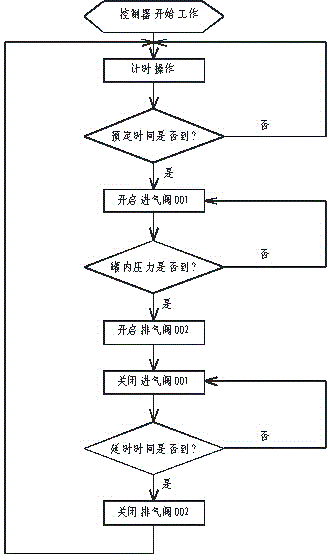

[0011] attached by figure 1 It can be seen that the present invention includes the ash-dispersing tank 2 and the emptying main pipe 1 and the intake main pipe 4 connected thereto, and also includes the ash-inlet main pipe 3 and the ash-out main pipe 5 connected with the ash-dispersing tank 2, and the described emptying main pipe 1 A bypass exhaust valve 002 is provided on the pipeline connected with the ash scattered tank 2, and a bypass air intake valve 001 is provided on the pipeline connected with the ash scattered tank 2 of the air intake main pipe 4. See attached figure 2 , the purging steps are as follows: a. Open the system controller, start the preset metering and control operation, and when the preset time is reached, the bypass intake valve 001 is opened; b. Monitor whether the preset pressure in the ash tank 2 reaches the set value When the value is reached, the bypass exhaust valve 002 is opened, and the intake valve 001 is closed at the same time; c. After the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com