Cement mortar for long cementing segment and large temperature difference salt-gypsum bed well cementation, and preparation method thereof

A technology of large temperature difference and salt paste layer, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as potential safety hazards, poor performance of cement slurry, performance changes of cement slurry admixtures, etc., to achieve good gas channeling prevention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

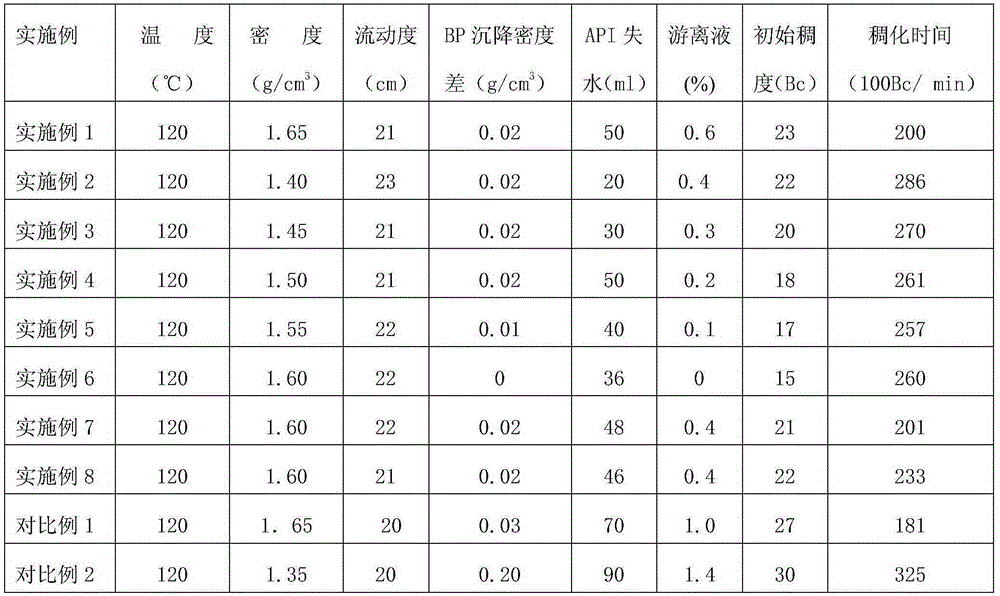

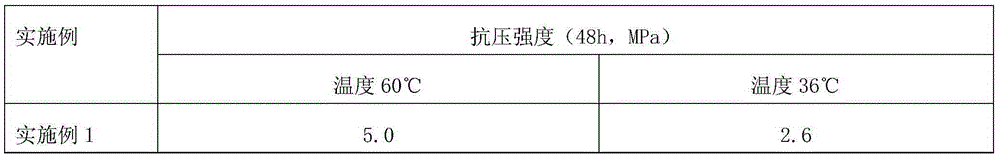

Examples

Embodiment 1

[0036] Weigh 100 parts of oil well G grade cement, 8 parts of silica powder (purity ≥ 98%, particle size 0.1 μm-0.3 μm), 10 parts of hollow glass microspheres, 1 part of 2-acrylamido-2 methylpropane Sulfonic acid polymer, 0.5 part of aliphatic hydroxysulfonate condensate, 0.5 part of bentonite, 1 part of calcium oxide, 1 part of sulphate and 0.5 part of basalt fiber, mixing and stirring the above materials to obtain a dry blend material;

[0037] Weigh 0.5 parts of 2-acrylamido-2 methylpropanesulfonic acid polymer and 0.1 part of tributyl phosphate, and dissolve them uniformly in 77 parts of sodium chloride solution with a mass concentration of 18%, stir evenly, and prepare get wet mix materials;

[0038] Stir the above-mentioned wet-mixed material at a speed of 4000r / min, while stirring, add the above-mentioned dry-mixed material into the above-mentioned wet-mixed material at a uniform speed to obtain cement slurry for cementing salt-gypsum layers with large temperature diffe...

Embodiment 2

[0040] Weigh 100 parts of oil well G grade cement, 15 parts of silica powder (purity ≥ 98%, particle size 0.1 μm-0.3 μm), 20 parts of hollow glass microspheres, 4 parts of 2-acrylamido-2 methylpropane Sulfonic acid polymer, 2 parts of aliphatic hydroxysulfonate condensate, 2 parts of bentonite, 3 parts of calcium oxide, 3 parts of sulfate and 2 parts of basalt fiber, the above materials are mixed and stirred evenly to obtain a dry blend material;

[0041] Weigh 2 parts of 2-acrylamido-2 methylpropanesulfonic acid polymer and 0.3 part of tributyl phosphate, and dissolve them uniformly in 100 parts of sodium chloride solution with a mass concentration of 18%, stir evenly, and prepare get wet mix materials;

[0042] Stir the above-mentioned wet-mixed material at a speed of 4000r / min, and at the same time, add the above-mentioned dry-mixed material to the above-mentioned wet-mixed material at a uniform speed to obtain the cement slurry for cementing the salt-gypsum layer with larg...

Embodiment 3

[0044] Weigh 100 parts of oil well G grade cement, 10 parts of silica powder (purity ≥ 98%, particle size 0.1 μm-0.3 μm), 13 parts of hollow glass microspheres, 2 parts of 2-acrylamide-2-methylpropane Sulfonic acid polymer, 0.8 part of aliphatic hydroxysulfonate condensate, 0.9 part of bentonite, 1.5 part of calcium oxide, 1.6 part of sulfate and 0.8 part of basalt fiber, the above materials are mixed and stirred evenly to obtain a dry blend material;

[0045] Weigh 0.8 parts of 2-acrylamido-2 methylpropanesulfonic acid polymer and 0.15 parts of tributyl phosphate, and dissolve them uniformly in 83 parts of sodium chloride solution with a mass concentration of 18%, stir evenly, and prepare get wet mix materials;

[0046] Stir the above-mentioned wet-mixed material at a speed of 4000r / min, and at the same time, add the above-mentioned dry-mixed material to the above-mentioned wet-mixed material at a uniform speed to obtain the cement slurry for cementing the salt-gypsum layer w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com