Novel light weight board

A lightweight, board-based technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as danger, occupancy, and poor sound insulation, and achieve good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

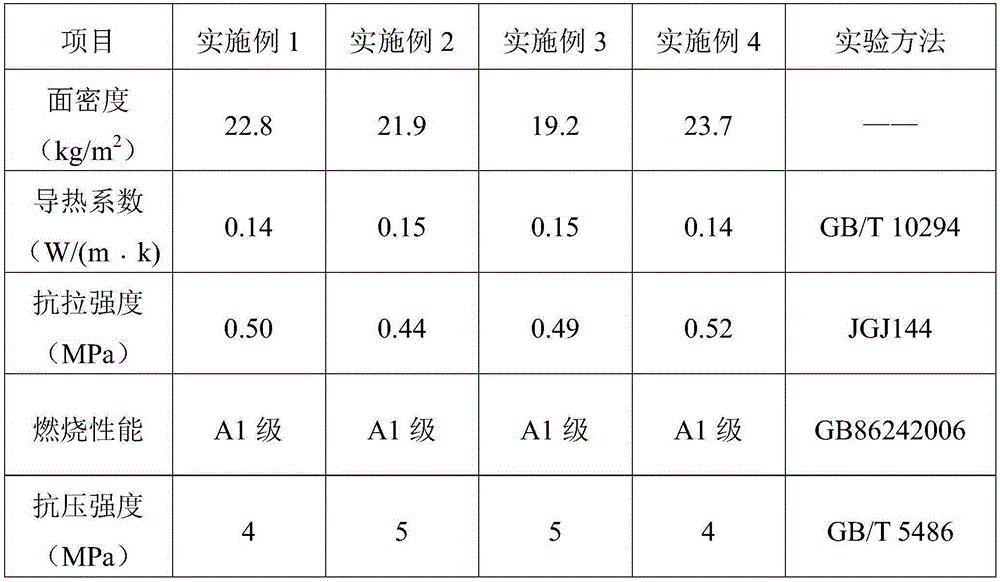

Examples

Embodiment 1

[0018] The present embodiment includes the following raw material components in parts by weight:

[0019] 150 parts of cement, 65 parts of fly ash, 40 parts of silicate, 50 parts of carboxymethyl cellulose, 15 parts of latex powder, and 20 parts of calcium stearate.

[0020] The preparation method of the plate of the present embodiment is as follows:

[0021] Weigh each component according to the above parts by weight, first add cement, fly ash and silicate to water and mix to obtain a mixed slurry, wherein the mass ratio of the total mass of cement, fly ash and silicate to water is 1 : 4, then carboxymethyl cellulose, latex powder and calcium stearate are added in the mixed slurry successively and stirred evenly, finally inject molding in the plate forming mold, obtain described novel lightweight plate.

Embodiment 2

[0023] The present embodiment includes the following raw material components in parts by weight:

[0024] 250 parts of cement, 50 parts of fly ash, 60 parts of silicate, 30 parts of carboxymethyl cellulose, 25 parts of latex powder, and 5 parts of calcium stearate.

[0025] The preparation method of the plate of the present embodiment is as follows:

[0026] Weigh each component according to the above parts by weight, first add cement, fly ash and silicate to water and mix to obtain a mixed slurry, wherein the mass ratio of the total mass of cement, fly ash and silicate to water is 1 : 3, then carboxymethyl cellulose, latex powder and calcium stearate are added in the mixed slurry successively and stirred evenly, finally inject molding in the plate forming mold, obtain described novel lightweight plate.

Embodiment 3

[0028] The present embodiment includes the following raw material components in parts by weight:

[0029] 220 parts of cement, 60 parts of fly ash, 55 parts of silicate, 43 parts of carboxymethyl cellulose, 18 parts of latex powder, and 15 parts of calcium stearate.

[0030] The preparation method of the plate of the present embodiment is as follows:

[0031] Weigh each component according to the above parts by weight, first add cement, fly ash and silicate to water and mix to obtain a mixed slurry, wherein the mass ratio of the total mass of cement, fly ash and silicate to water is 3 : 4, then carboxymethyl cellulose, latex powder and calcium stearate are added in the mixed slurry successively and stirred evenly, finally inject molding in the plate forming mold, obtain described novel lightweight plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com