Re-preheating impregnation method for unqualified impregnated graphite product

A graphite impregnation treatment technology, which is applied in the field of re-preheating impregnation of unqualified graphite impregnation products, can solve problems such as uneven impregnation and asphalt coking, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Preheat

[0051] (1) Freely heat up unqualified graphite impregnated products from ambient temperature to 145°C;

[0052] (2) Then raise the temperature to 195°C at a heating rate of 3.5°C / h. After this stage is completed, remove the impurities on the outer surface of the product;

[0053] (3) Then raise the temperature to 315°C at a heating rate of 12.5°C / h, and clean the impurities on the surface again after being released from the furnace;

[0054] (4) Finally, keep the temperature at 315°C for 6 hours, and the preheating is over;

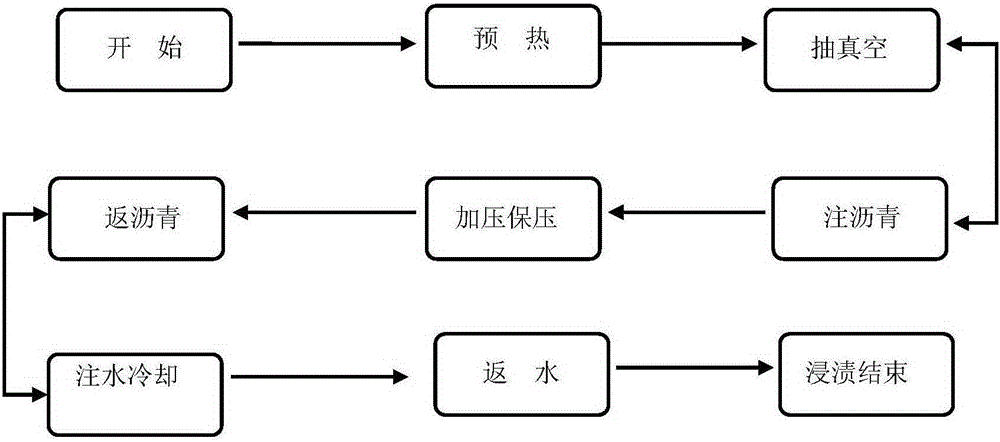

[0055] 2. Dipping

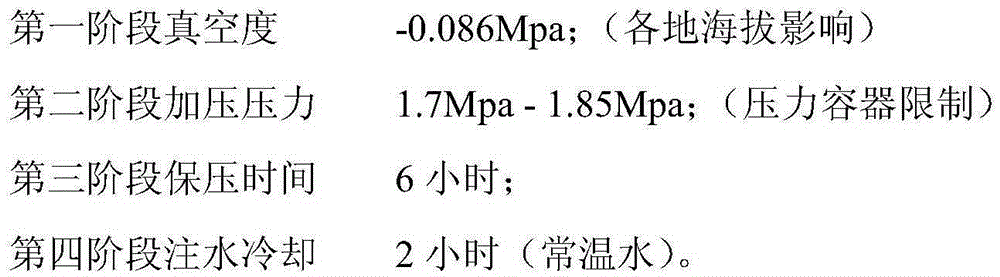

[0056] The preheated unqualified graphite impregnated products are placed in the impregnating equipment, vacuumized, the vacuum degree is -0.086MPa, and then the asphalt is injected into the impregnating equipment to form an impregnating system, and the impregnating system is applied with a pressure of 1.7-1.85Mpa for impregnation For processing, keep the pressure constant for 8 hours, then inject normal temperat...

Embodiment 2

[0058] 1. Preheat

[0059] (1) Freely raise the temperature of unqualified graphite impregnated products from ambient temperature to 150°C;

[0060] (2) Then raise the temperature to 200°C at a heating rate of 3.5°C / h. After this stage is completed, remove the impurities on the outer surface of the product;

[0061] (3) Then raise the temperature to 320°C at a heating rate of 12.5°C / h, and clean the impurities on the surface again after being released from the furnace;

[0062] (4) Finally, keep the temperature at 320°C for 6 hours, and the preheating is over;

[0063] 2. Dipping

[0064] The preheated unqualified graphite impregnated products are placed in the impregnating equipment, vacuumized, the vacuum degree is -0.086MPa, and then the asphalt is injected into the impregnating equipment to form an impregnating system, and the impregnating system is applied with a pressure of 1.7-1.85Mpa for impregnation For processing, keep the pressure constant for 8 hours, then injec...

Embodiment 3

[0066] 1. Preheat

[0067] (1) Freely heat up unqualified graphite impregnated products from ambient temperature to 155°C;

[0068] (2) Then the temperature is raised to 205°C at a heating rate of 3.5°C / h. After this stage is completed, the impurities on the outer surface of the product are removed;

[0069] (3) Then raise the temperature to 325°C at a heating rate of 12.5°C / h, and clean the impurities on the surface again after being released from the furnace;

[0070] (4) Finally, keep the temperature at 325°C for 6 hours, and the preheating is over;

[0071] 2. Dipping

[0072] The preheated unqualified graphite impregnated products are placed in the impregnating equipment, vacuumized, the vacuum degree is -0.086MPa, and then the asphalt is injected into the impregnating equipment to form an impregnating system, and the impregnating system is applied with a pressure of 1.7-1.85Mpa for impregnation For processing, keep the pressure constant for 8 hours, then inject normal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com