Peony culture soil and preparation method thereof

A technology for cultivating soil and peonies, applied in the field of agronomy, to achieve the effects of disease prevention, smooth drainage, and improvement of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

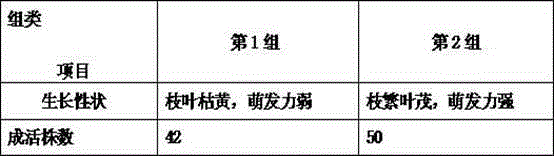

Examples

Embodiment 1

[0021] Step 1: Preparation of corn stalk powder: put the corn stalk into a pulverizer and pulverize it to form the initial raw material, let it dry naturally, and then grind it into a powder, pass it through a 200-mesh sieve and take the powder for use;

[0022] Step 2: Preparation of celery, kelp, and radish: choose fresh celery, radish, and kelp, and cut them into soybean-sized granules for later use;

[0023] Step 3: Take 8-10 parts of corn stalk powder, 6-8 parts of celery, 5-6 parts of seaweed, 6-10 parts of radish and 4-5 parts of rapeseed cake by weight components 1. 3-5 parts of chicken manure, stir and mix and place in a sealed tank, add water at a ratio of 1:0.2, and keep it at 50-60°C for sealed fermentation, ferment for 20-25 days, stir once every 5-6 days , after fermentation, dry and pulverize for later use;

[0024] Step 4: Weigh 30-40 parts of slag and 20-30 parts of leaf humus according to the weight components, and select leaf humus and slag as the main matr...

Embodiment 2

[0026] Step 1: Preparation of corn stalk powder: put the corn stalk into a pulverizer and pulverize it to form the initial raw material, let it dry naturally, and then grind it into a powder, pass it through a 200-mesh sieve and take the powder for use;

[0027] Step 2: Preparation of celery, kelp, and radish: choose fresh celery, radish, and kelp, and cut them into soybean-sized granules for later use;

[0028] Step 3: Take 10 parts of corn stalk powder, 8 parts of celery, 5 parts of seaweed, 8 parts of radish and 4 parts of rapeseed cake, and 4 parts of chicken manure according to the weight components, stir and mix and place In a sealed tank, add water at a ratio of 1:0.2, and keep it at 50-60°C for sealed fermentation, ferment for 20-25 days, stir once every 5-6 days, dry and crush for use after fermentation;

[0029] Step 4: Weigh 35 parts of slag and 25 parts of mulch soil according to the weight components, and select mulch soil and slag as the main matrix, stir evenly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com