Hydroxyl complex heat stabilizer, compound heat stabilizer, polyvinyl chloride resin composition and preparing method

A composite heat stabilizer and polyvinyl chloride resin technology, which is applied in the field of hydroxyl complex heat stabilizers and polyvinyl chloride resin compositions, can solve problems such as easy crystallization, difficult removal, difficult precipitation, and stable effects, and achieves Improve processing performance, improve thermal stability, good stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention provides the preparation method of above-mentioned thermal stabilizer, and this method comprises at least one in the following steps:

[0024] (1) Mix the hydroxyl compound and the zinc-containing compound uniformly, and heat at 130-200°C for 2-10h, cool the resulting mixture to 25-60°C, and then add low-carbon alcohol to form a uniform slurry. The slurry is centrifuged, washed, and dried to obtain the hydroxyzinc complex;

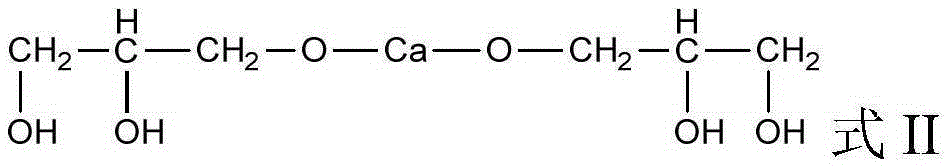

[0025] (2) Mix calcium-containing compound, hydroxy compound and low-carbon alcohol evenly, react under the reflux condition of low-carbon alcohol for 1-10 h, cool to room temperature, suction filter, wash and dry to obtain calcium hydroxy complex.

[0026] For the case where the hydroxyzinc complex and the hydroxycalcium complex are used together, the hydroxyzinc complex and the hydroxycalcium complex are respectively prepared according to the above steps and then mixed.

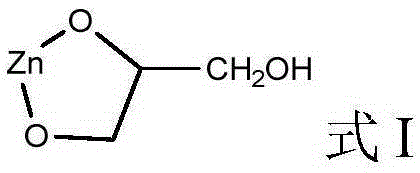

[0027] According to the present invention, the hydrox...

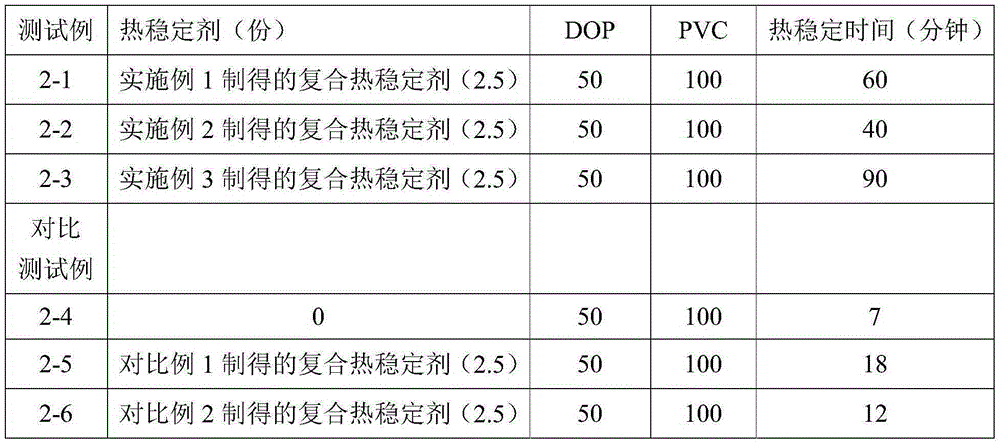

Embodiment 1

[0048] Weigh the hydroxyl compound, zinc oxide, and zinc carbonate according to the mass ratio of 120:30:1, and mix them thoroughly until a uniform slurry is obtained. The slurry was heated at a temperature of 130° C., and heated with uniform mixing at this temperature for 3 h. The mixture was cooled to 40°C and isopropanol was added and mixed for 15 min to form a homogeneous slurry. Centrifuge the slurry for 30 minutes, wash with isopropanol, centrifuge and dry to obtain the hydroxyzinc complex.

[0049] 40 parts by mass of hydroxyzinc complex, 20 parts by mass of calcium stearate, 20 parts by mass of zeolite, 4 parts by mass of β-diketone, 8 parts by mass of dipentaerythritol and 8 parts by mass of PE wax were mixed at high speed for 5 minutes, and then mixed on a double roller Knead on the open mill for 4-5 minutes, the plasticizing conditions are the speed of the front roller is 18r / min, the speed of the rear roller is 20r / min, the temperature of the roller is 170°C, and ...

Embodiment 2

[0051] Add 60g of calcium oxide into the methanol solution of 180g of hydroxyl compound, stir to make it evenly mixed. Then react under the reflux condition of methanol for 3.5h. Cool to room temperature, filter with suction, wash with ethanol three times, and then vacuum-dry at 60°C to constant weight to obtain calcium hydroxy complex.

[0052] 40 parts by mass of zinc stearate, 20 parts by mass of calcium hydroxy complex, 20 parts by mass of zeolite, 4 parts by mass of β-diketone, 8 parts by mass of dipentaerythritol and 8 parts by mass of PE wax were mixed at high speed for 5 minutes, and then mixed on a double roller Knead on the open mill for 4-5 minutes, the plasticizing conditions are the speed of the front roller is 18r / min, the speed of the rear roller is 20r / min, the temperature of the roller is 170°C, and the sheet is released after the plasticization is complete.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap