Constant-temperature health care heating crystal floor and production technology thereof

A heat energy and floor technology, which is applied in the field of constant temperature health care heat energy crystal floor and its production process, achieves the effects of high heat transfer coefficient, high adhesion and balanced indoor environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

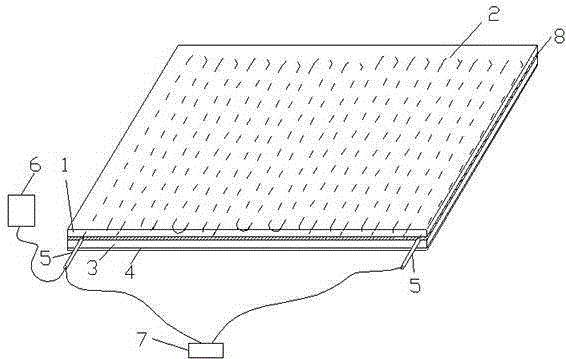

[0014] As shown in the figure, a constant temperature health care thermal energy crystal floor includes glass 1, nano-carbon ink alloy heating resistance wire 2, fireproof board 3, waterproof aluminum foil cloth 4 and thermostat 6, and the thermostat is an electronic frequency conversion thermostat. The nano-carbon ink alloy heating resistance wire 2 composite disk is fixed on the bottom of the glass 1, the fireproof board 3 is composited on the bottom of the nano-carbon ink alloy heating resistance wire 2, the bottom of the fireproof board 3 is provided with a waterproof aluminum foil cloth 4, and the nano-carbon ink alloy heating resistance wire 2 is worn The alloy terminals 5 connected to the side of the glass 1 are respectively connected to the temperature controller 6 and the power supply 7 , and the bottom of the glass 1 is provided with a pattern layer 8 . The production process of the constant temperature health care thermal energy crystal floor of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com