Backflush-cleanable and fast-calibration gas detection probe with multi-phase catalyst alloy, far-infrared and negative ion ceramic filters

A multi-phase catalyst alloy, far-infrared ceramic technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of large uncertainty, decreased sensitivity, short life, etc., and achieve the effect of accurate production and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

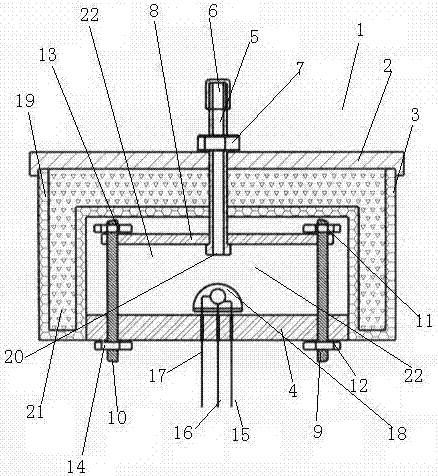

[0047] Such as figure 1 and figure 2 As shown, the gas detection probe 1 that can be backwashed and quickly calibrated using multi-phase catalyst alloy, far-infrared and negative ion ceramic filters is composed of the following components:

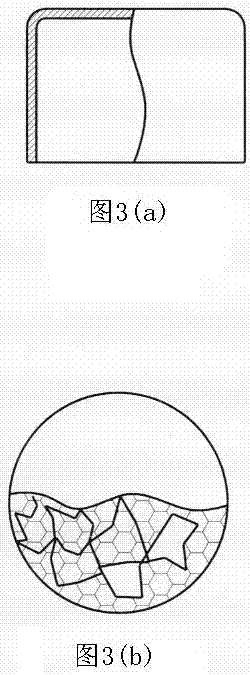

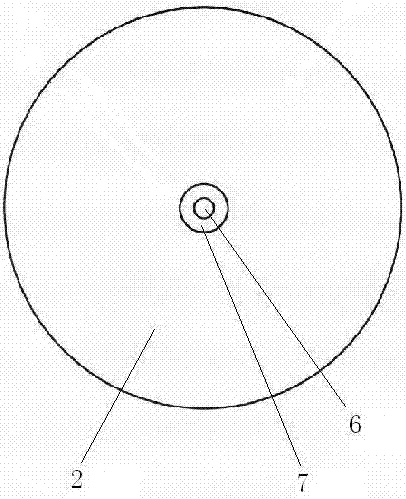

[0048]The stainless steel upper cover with convex edges around the edge 2, the "∏" shaped porous polytetrafluoroethylene core shell with excellent water repellency and non-wetting properties to most liquids 3, the hydrogen sulfide, sulfur dioxide, hexamethylsilane and other organic Sulfur-silicon gas such as silicon has strong irreversible adsorption and high reactivity, but it does not have reactivity and adsorption for hydrogen, natural gas and other alkanes and carbon monoxide, etc. "Π" shaped porous multiphase Catalyst alloy, negative ion, far-infrared ceramic catalyst assembly 21, stainless steel base 4, standard gas input and gas cleaning stainless steel blowback pipe 5, tightening nut 6, fastening nut 7, stainless steel fixing pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com