Thyristor detector and thyristor detection method of the detector

A detection method and thyristor technology, applied in the field of thyristor detection and thyristor detector, can solve the problems of unsuitable high-power thyristor detection, inconvenient thyristor detection, long detection time, etc., achieve comprehensive and accurate detection, shorten maintenance time, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

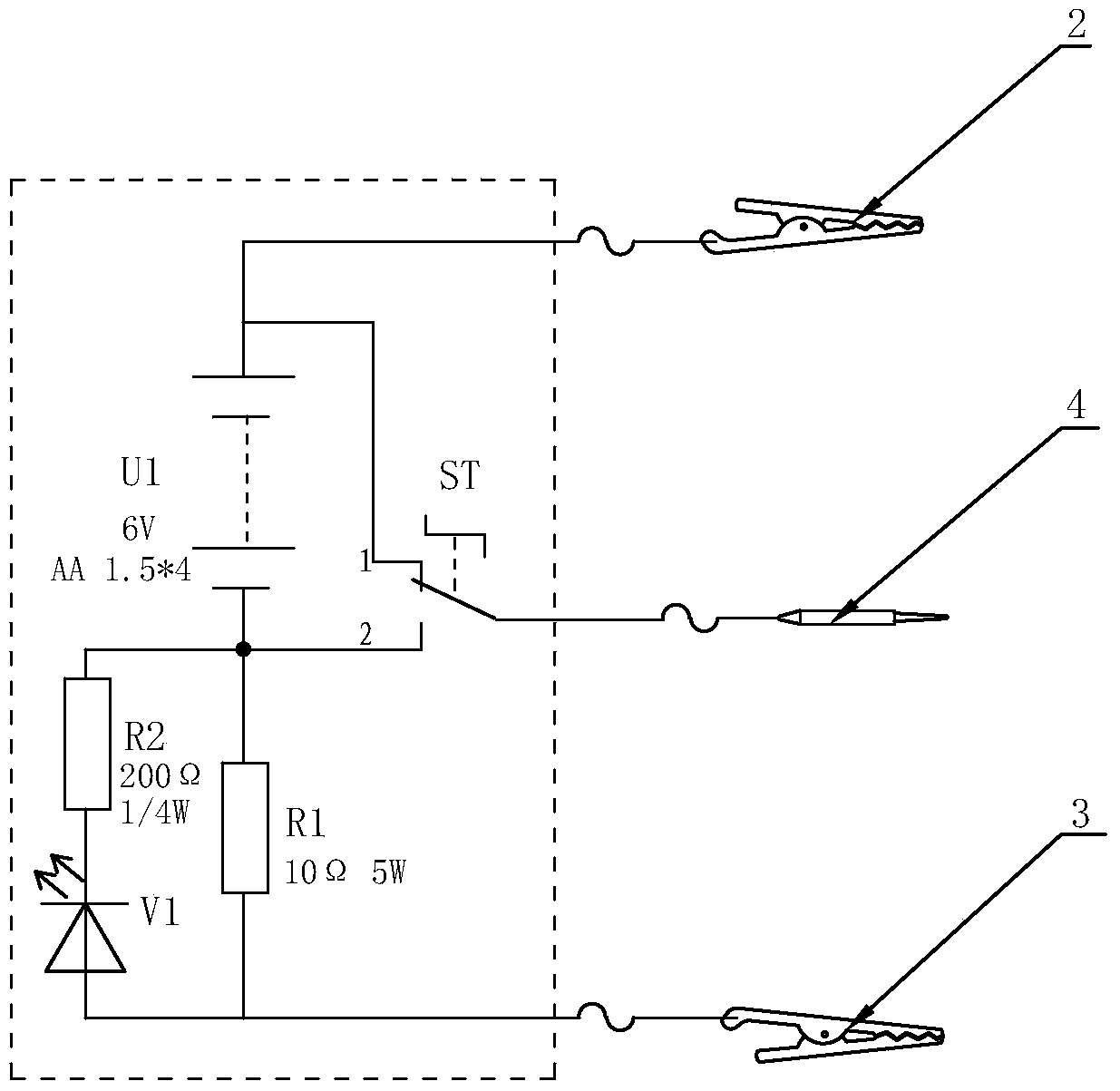

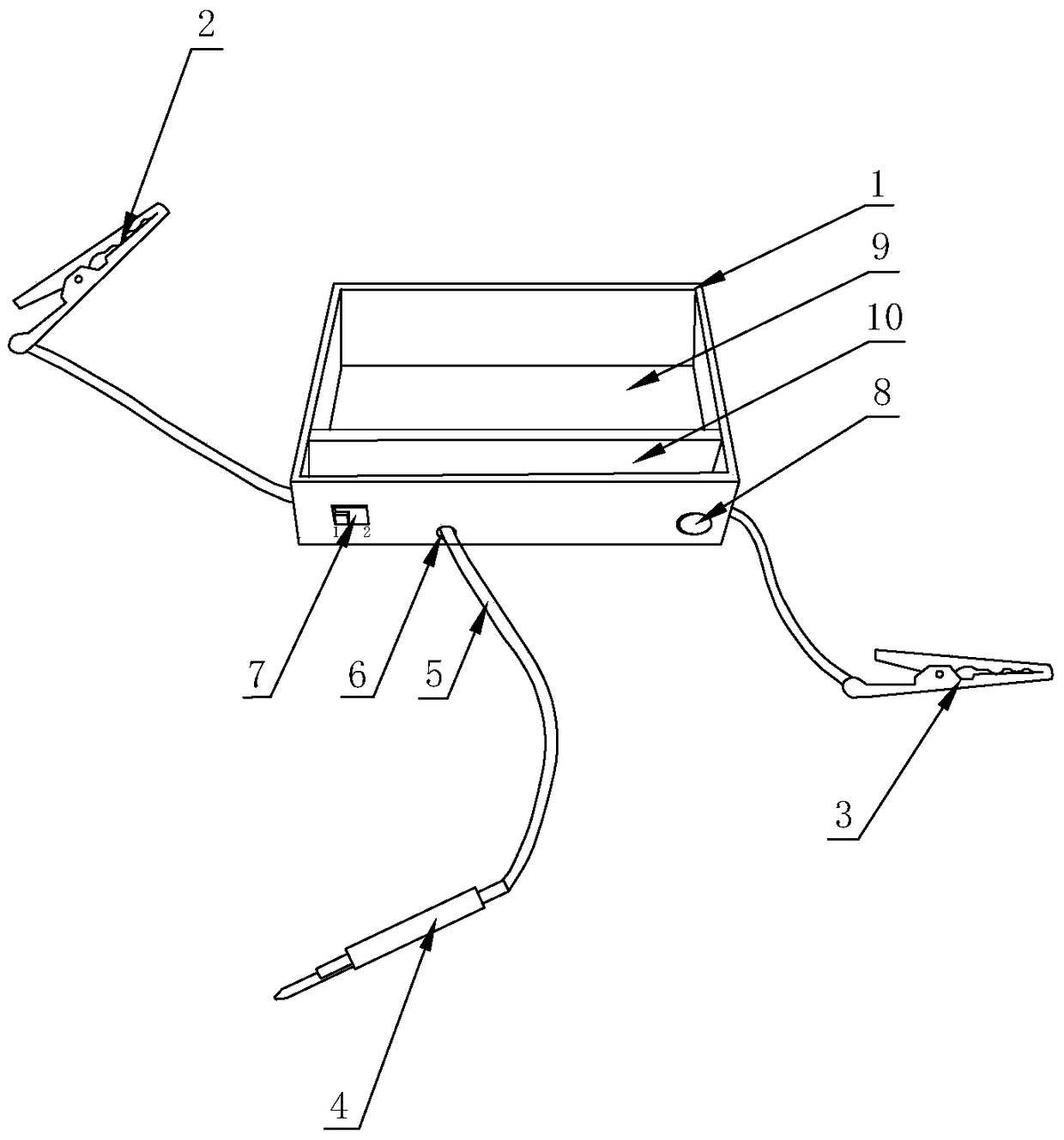

[0074] Such as Figure 1-2 As shown, a thyristor detector, the detector at least includes: a housing 1, a power supply, a load resistor R1, a light emitting diode V1, a light emitting diode current limiting resistor R2, a two-position switch ST, an anode clip 2, a cathode clip 3, The gate probe 4 and several wires 5; the shell 1 is a detachable cavity structure, and the left side, the right side and the middle part of the front side of the shell 1 are provided with wiring holes 6, and the front side of the shell 1 A switch installation hole 7 is provided at the left end, an indicator light installation hole 8 is provided at the front right end of the housing, and a battery slot 9 and a component slot 10 are provided in the housing cavity;

[0075] The power supply is set in the battery slot 9; the load resistor R1 and the light-emitting diode current-limiting resistor R2 are fixed in the component slot 10; the light-emitting diode V1 is installed in the installation hole 8 of ...

Embodiment 2

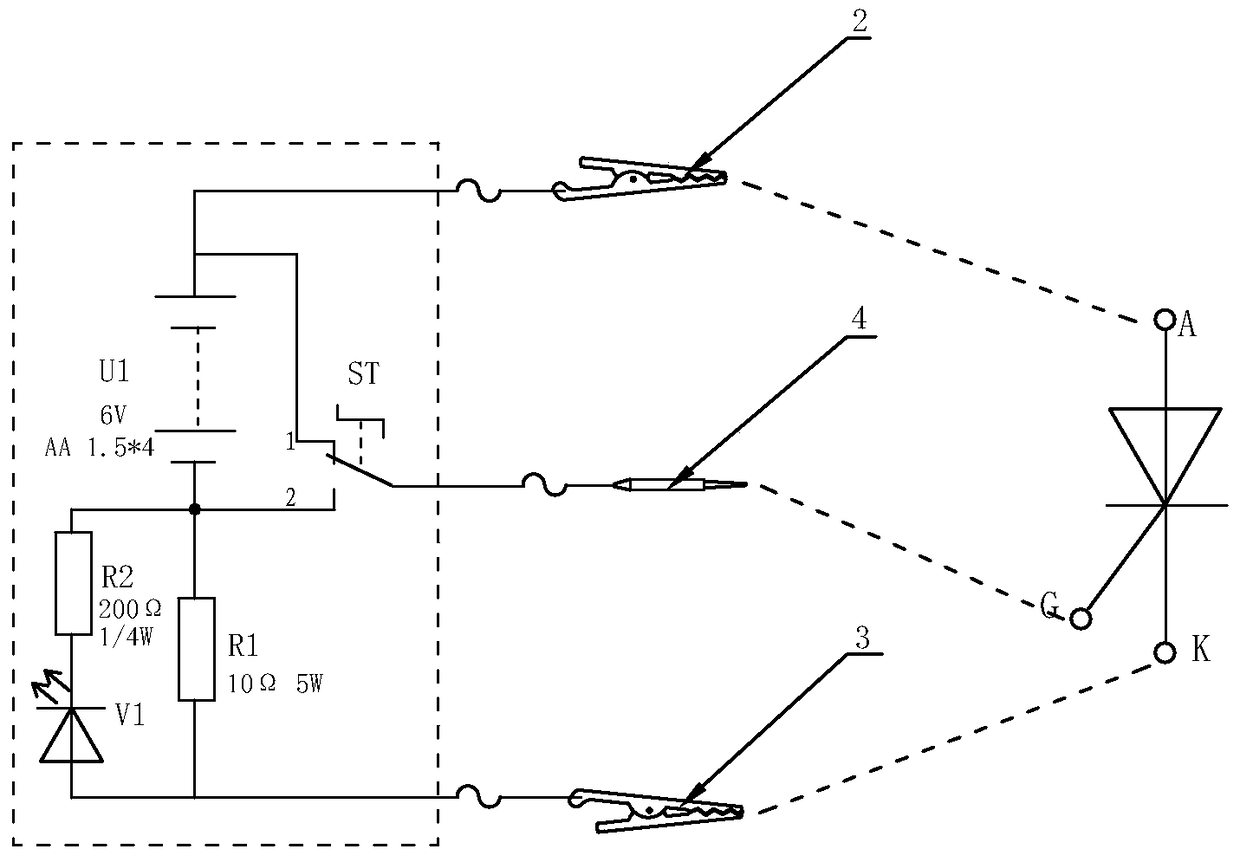

[0087] The connection method of ordinary thyristor detection circuit is as follows: image 3 As shown, the specific steps are as follows:

[0088] Step 1. Turn the two-position switch ST to the 1st gear contact;

[0089] Step 2, the anode clip 2 is connected to the anode A of the ordinary thyristor, and the cathode clip 3 is connected to the cathode K of the ordinary thyristor;

[0090] Step 3, the gate probe 4 touches the gate G of the ordinary thyristor;

[0091] Step 4. Analyze the results:

[0092] If the gate probe 4 does not touch the gate G of the ordinary thyristor and the light-emitting diode V1 lights up, then the anode A of the ordinary thyristor and the cathode K are short-circuited;

[0093] If the gate probe 4 does not touch the gate G of the ordinary thyristor, the light-emitting diode V1 does not light up, and the light-emitting diode V1 lights up and remains on after touching, then the ordinary thyristor is intact;

[0094] If the gate probe 4 does not tou...

Embodiment 3

[0096] The connection method of the bidirectional thyristor forward detection circuit is as follows: Figure 4 As shown, the specific steps are as follows:

[0097] Step 1. Turn the two-position switch ST to the 1st gear contact;

[0098] Step 2, the anode clamp 2 is connected to the second anode T2 of the triac, and the cathode clamp 3 is connected to the first anode T1 of the triac;

[0099] Step 3, the gate probe 4 touches the triac gate G3;

[0100] Step 4. Analyze the results:

[0101] If the gate probe 4 does not touch the gate G3 of the triac and the light-emitting diode V1 lights up, the anode and cathode of the triac are short-circuited;

[0102] If the gate probe 4 does not touch the gate G3 of the triac, the light-emitting diode V1 does not light up, and the light-emitting diode V1 lights up and remains on after touching, then the triac is intact;

[0103] If the gate probe 4 does not touch the gate G3 of the bidirectional thyristor, the light emitting diode V1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com