Process optimization control method and process optimization control system for main steam system of ultra-supercritical unit

An ultra-supercritical unit and main steam system technology, which is applied in the field of electric power systems and can solve the problems of inability to meet the control requirements of ultra-supercritical units, low control efficiency, and large temperature fluctuations in the main steam system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

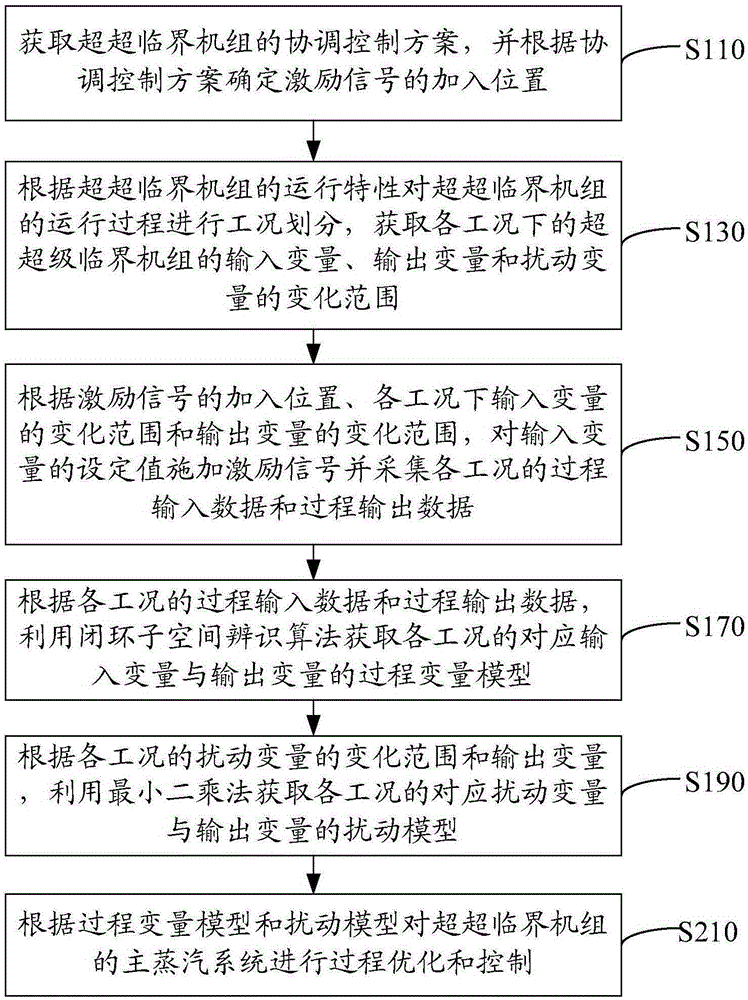

[0033] refer to figure 1 , the method for process optimization control of the main steam system of an ultra-supercritical unit in an embodiment of the present invention includes the following steps.

[0034] S110: Obtain the coordinated control scheme of the ultra-supercritical unit, and determine the adding position of the excitation signal according to the coordinated control scheme.

[0035] Coordinated control schemes include boiler-following-based control schemes and turbine-following-based control schemes. In this embodiment, specifically, the coordinated control scheme can be determined by determining the structure, form and communication mode of the multivariable constrained controller.

[0036] S130: According to the operating characteristics of the ultra-supercritical unit, divide the operation process of the ultra-supercritical unit into working conditions, and obtain the variation ranges of input variables, output variables and disturbance variables of the ultra-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com