Ultra-small ultra-thin high-luminous-efficiency lateral-emission-type high-light white-light LED element

A high-efficiency, LED chip technology, applied in the direction of electrical components, electrical solid-state devices, semiconductor devices, etc., can solve the problems of large size, high-brightness white light cannot solve the problem of heat dissipation, high thermal resistance of PCB, etc., to achieve space saving and good heat dissipation effect , the effect of reducing the size of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

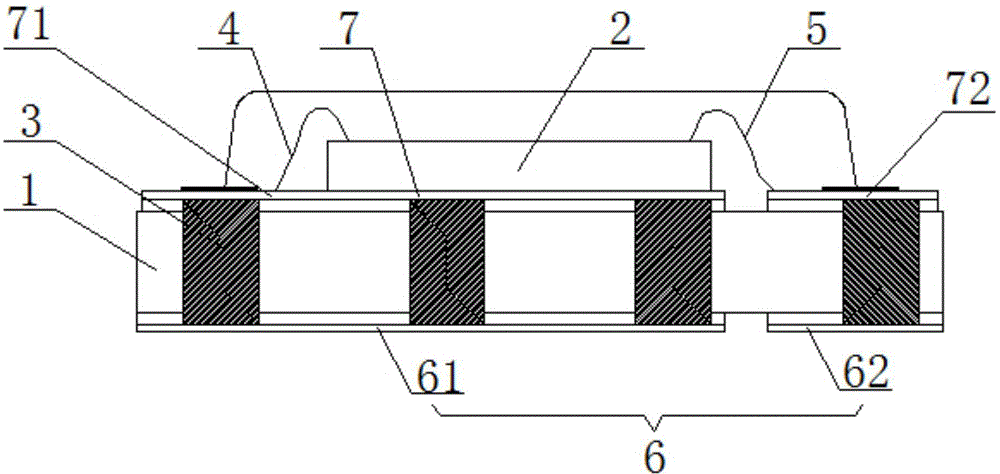

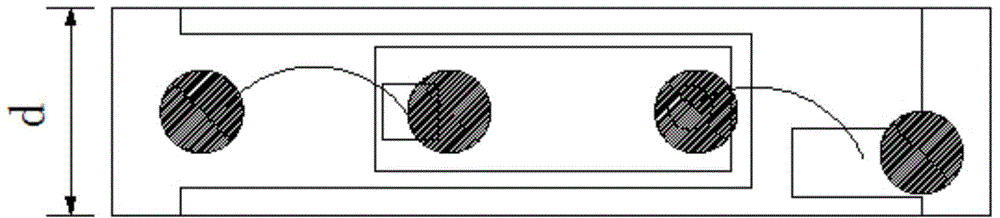

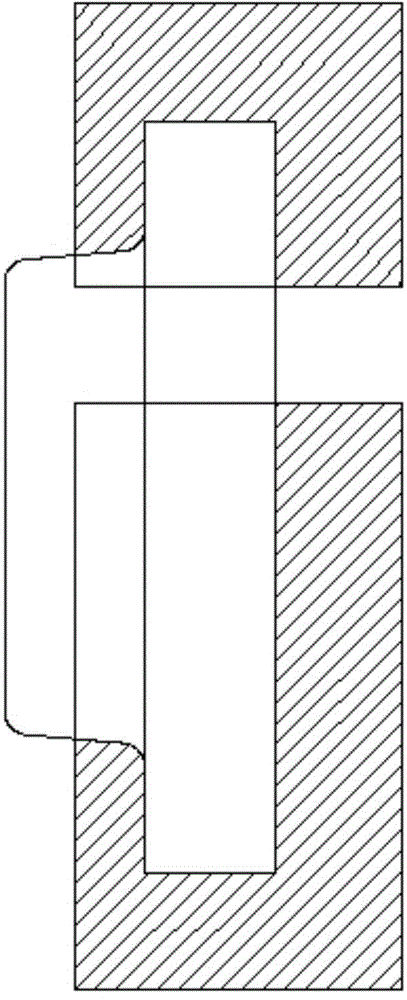

[0029] Such as figure 1 An ultra-small, ultra-thin, high-efficiency side-emitting high-brightness white LED element shown includes a substrate 1 and a light-emitting LED chip 2 , and the light-emitting LED chip 2 is fixed on the substrate 1 . The substrate 1 is provided with a number of via holes penetrating through its upper and lower bottom surfaces, and conductors 3 are filled in the via holes, and the anode of the light-emitting LED chip 2 connects with the anode wire 4 in one of the via holes. The conductor 3 is electrically connected, and the negative electrode of the light-emitting LED chip 2 is electrically connected to the conductor 3 in another via hole through the negative electrode wire 5 . Preferred embodiment: the conductor 3 is a copper pillar or conductive glue.

[0030] The lower bottom surface of the substrate 1 is covered with a first metal conductive layer 6, the metal conductive layer 6 is divided into a positive electrode region 61 and a negative electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com