Wide-speed adjustable direct-axis magnetic field-enhanced permanent magnet brushless motor for vehicles and its zoned magnetic regulation control

A permanent magnet brushless motor, wide speed regulation technology, applied to synchronous motors with static armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of small speed regulation range. , the problem of high efficiency operation, to achieve the effect of wide speed regulation range, high efficiency operation, and increasing direct shaft inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

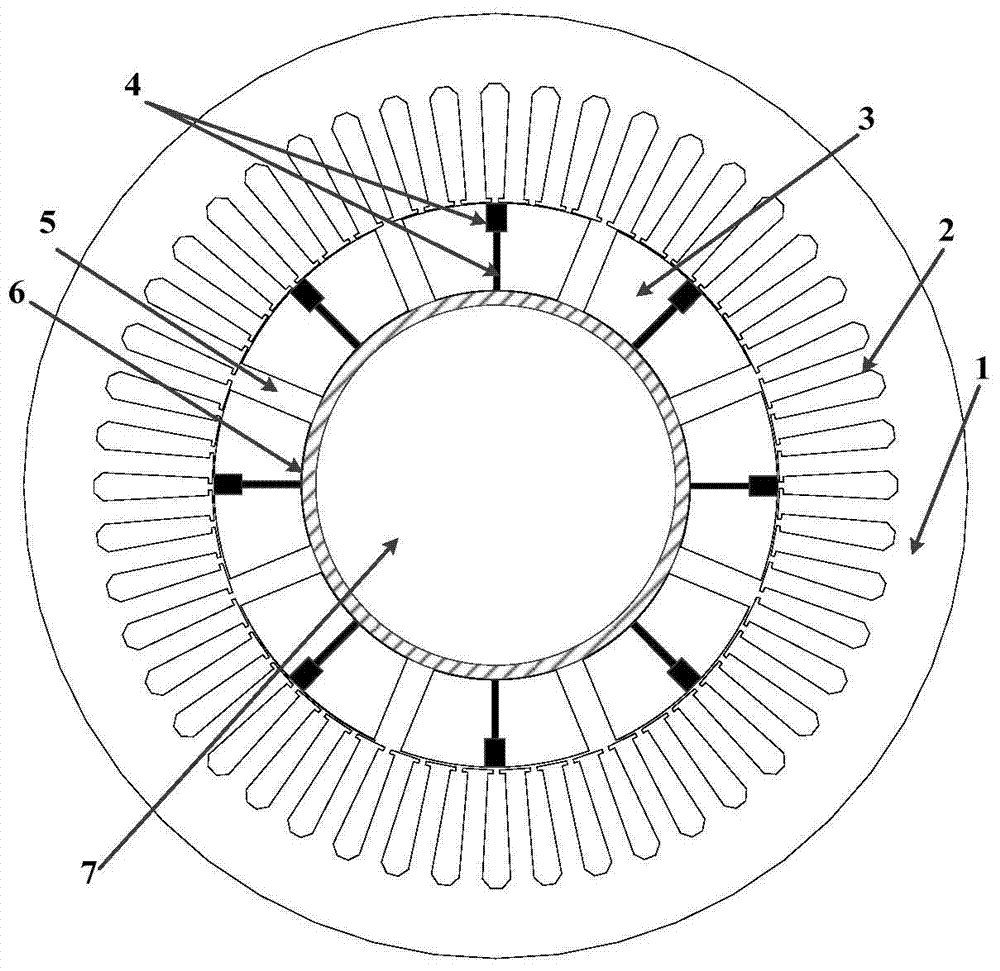

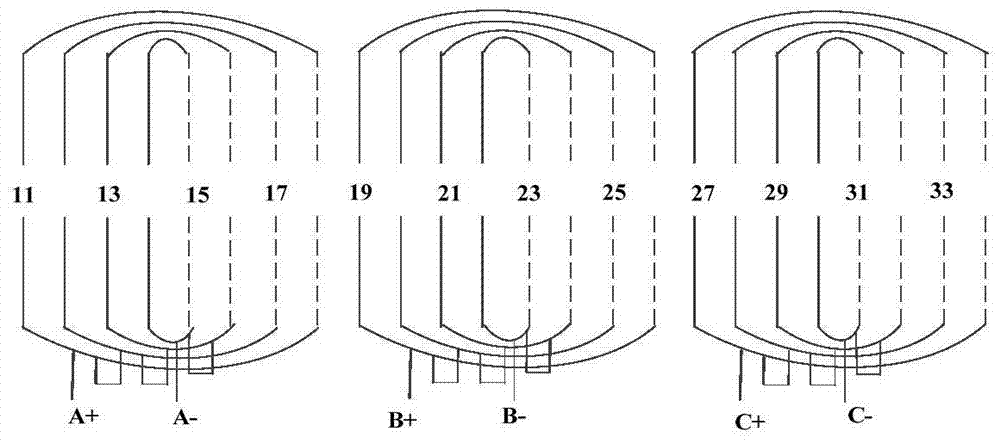

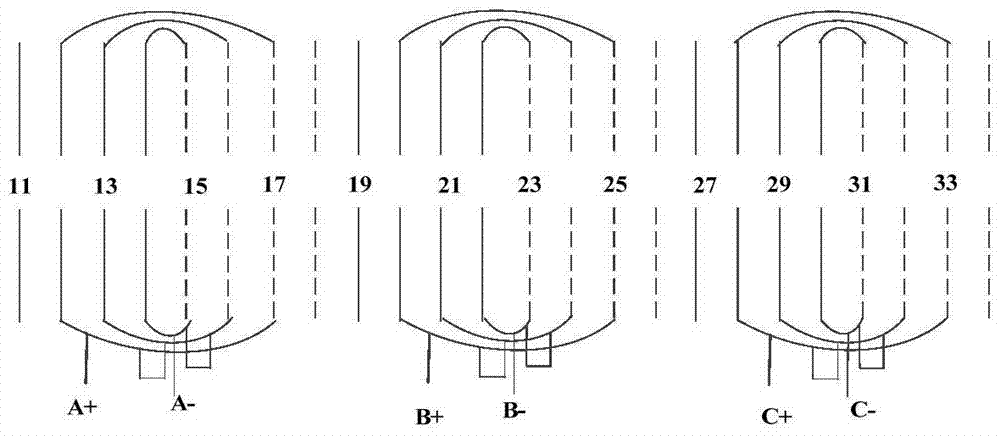

[0040] see figure 1 As shown, the present invention includes a stator 1, a rotor 3, a nonmagnetic bush 6 and a rotating shaft 7. The rotor 3 is located inside the stator 1 , and the center of the rotor 3 is slotted for placing the rotating shaft 7 . There is an air gap between the inner wall of the stator 1 and the outer wall of the rotor 3, the thickness of which is related to the power level of the motor and the assembly process. The stator 1 and the rotor 3 are formed by laminating silicon steel sheets with a thickness of 0.35 mm, and the lamination coefficient is 0.95. The armature slots 2 are evenly distributed along the circumference of the stator 1, and the single-layer armature windings are placed in the armature slots 2. The armature winding can be arranged according to the distributed winding of the traditional permanent magnet brushless motor. The armature winding under each permanent magnet pole spans 5 stator slots 2. The armature windings with the same spatial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com