Method for automatically identifying asynchronous motor rotor time constant by frequency converter

A rotor time constant, asynchronous motor technology, applied in the direction of motor generator control, control generator, electronic commutation motor control, etc., can solve the influence of motor control effect, current, voltage measurement error, rotor time constant and actual value deviation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

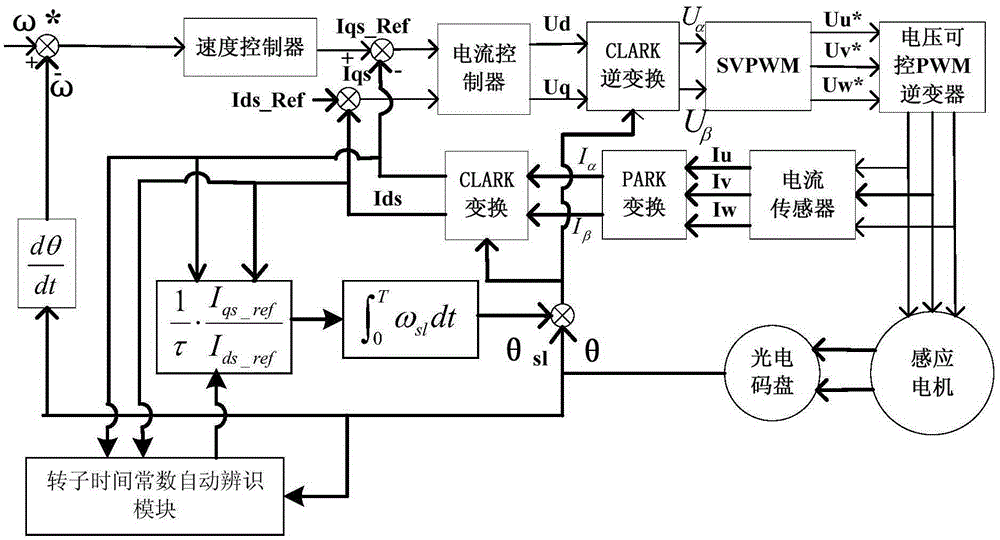

Image

Examples

Embodiment 1

[0060] The method for automatically identifying the rotor time constant of an asynchronous motor according to Embodiment 1 includes the following steps:

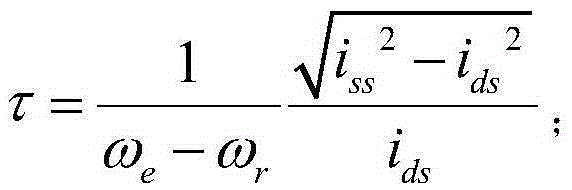

[0061] Step a, calculate the approximate value τ of the rotor time constant according to the following formula;

[0062] τ = 1 ω e - ω r i s s 2 - i d s 2 i d s ;

[0063] Among them, ω e is the rated stator current angu...

Embodiment 2

[0076] The method for the inverter to automatically identify the rotor time constant of the asynchronous motor includes the following steps:

[0077] Step a, calculate the approximate value τ of the rotor time constant according to the following formula;

[0078] τ = 1 ω e - ω r i s s 2 - i d s 2 i d s ;

[0079] Among them, ω e is the rated stator current angular velocity...

Embodiment 3

[0092] The method for automatically identifying the rotor time constant of an asynchronous motor according to Embodiment 3 includes the following steps:

[0093] Step a, calculate the approximate value τ of the rotor time constant according to the following formula;

[0094] τ = 1 ω e - ω r i s s 2 - i d s 2 i d s ;

[0095] Among them, ω e is the rated stator current angu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com