Circuit board automatic wiring machine

A technology of experimental boards and wiring machines, applied in the direction of electrical components, electrical components, etc., can solve the problems of long time to complete the work, complicated production process, affecting the operation of technicians, etc., to achieve time-consuming and labor-intensive, high accuracy, and precise placement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

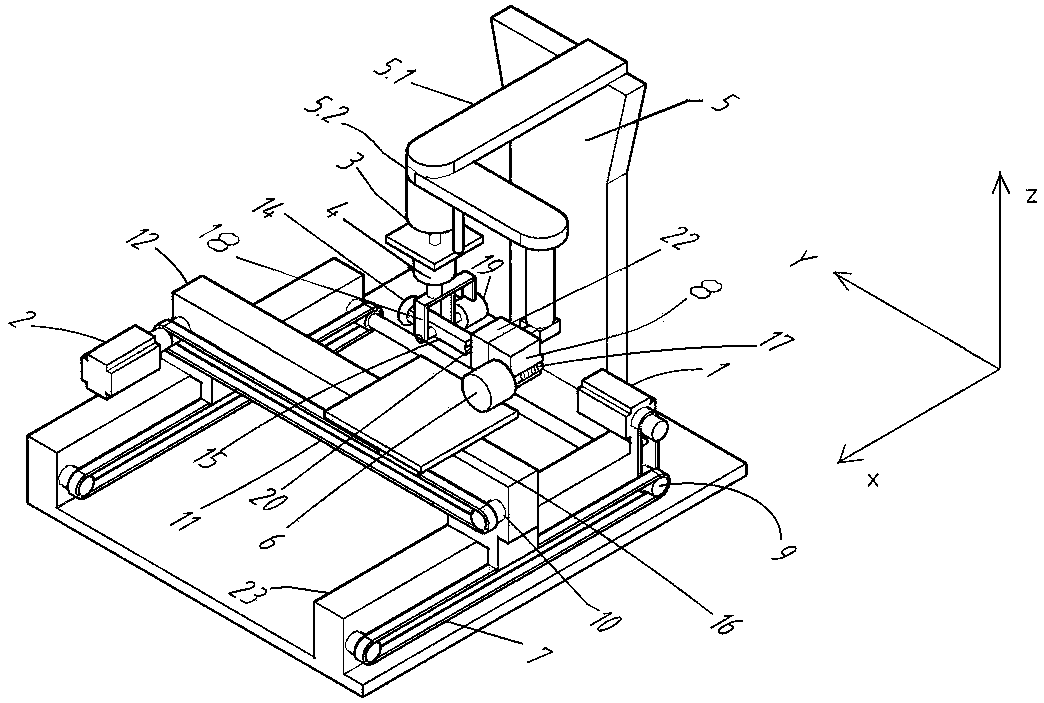

[0043] Embodiment 1, with reference to figure 1 , figure 2 , Figure 4 with Figure 5 : It includes a wiring manipulator and a breadboard moving mechanism for aligning the wiring manipulator;

[0044] The breadboard moving mechanism includes an x-axis movement mechanism and a y-axis movement mechanism for translating the breadboard 16 to be wired;

[0045] The x-axis moving mechanism includes an x-axis driving component for providing moving power, an x-axis transmission component connected to the x-axis driving component, and an x-axis moving component arranged on the x-axis transmission component;

[0046] The y-axis moving mechanism includes a y-axis driving component for providing moving power, a y-axis transmission component connected to the y-axis driving component, and a y-axis moving component arranged on the y-axis transmission component;

[0047] The y-axis driving part and the y-axis transmission part of the y-axis moving mechanism are fixed on the x-axis moving...

Embodiment 2

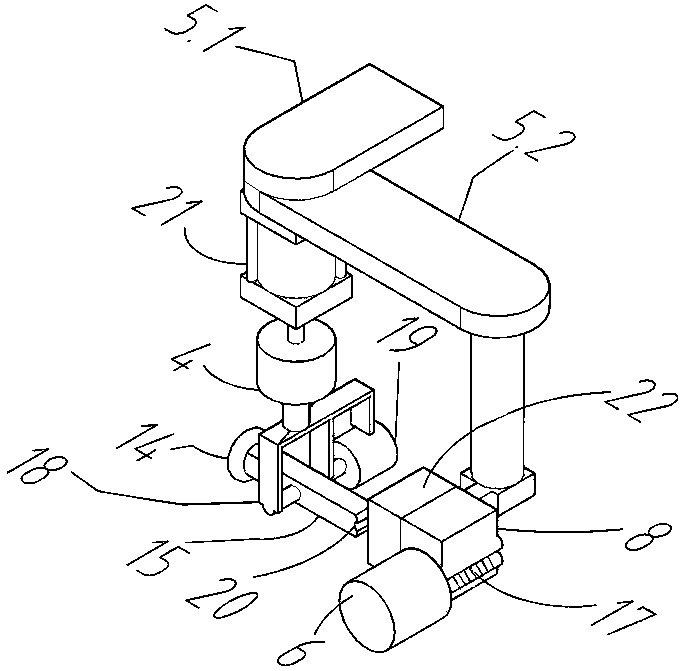

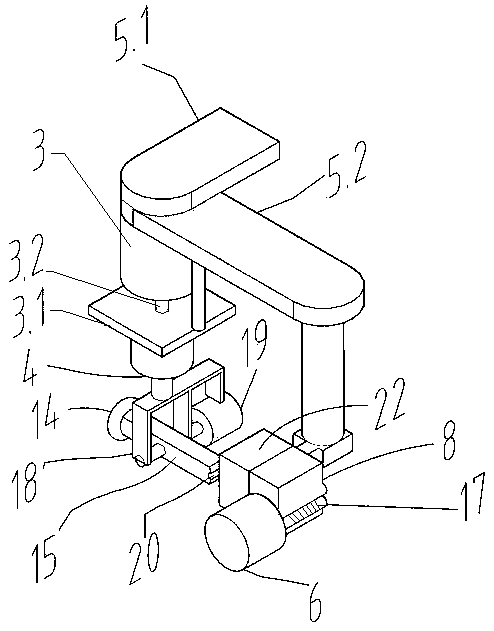

[0055] Embodiment 2, with reference to figure 1 , image 3 , Figure 4 with Figure 5 : the telescopic pressing mechanism is a pressing stepping motor 3 and a leading screw; the leading screw includes a screw 3.2 and a nut 3.1 moving up and down along the screw 3.2; the pressing stepping motor 3 is fixed below the pressing frame 5, And the output shaft of the pressing down stepper motor 3 is vertically downward, the screw rod 3.2 is coaxially connected with the output shaft of the pressing down stepping motor 3, and the wiring mechanism is fixed on the nut 3.1 for pressing down . Other technical characteristics are identical with embodiment 1.

Embodiment 3

[0056] Embodiment 3, with reference to Figure 1~Figure 5 : on the basis of embodiment 1 or embodiment 2, it further includes a feeding mechanism that delivers conductive wire 17 to magnetized metal rod 15 in the wiring mechanism, and the feeding mechanism includes winding wire stepping motor 6 and for The electric cutter 8 for cutting the conductive wire 17; the output shaft of the wire-wound stepper motor 6 is wound with a conductive wire 17, and the free end of the conductive wire 17 passes through the electric cutter 8 to the wiring mechanism 15 places in the magnetized metal rod.

[0057] Further, the electric cutter 8 includes an upper blade 8.2 and a lower blade 8.1 connected by a rivet; with the rivet as a boundary, a spring 8.3 is arranged between the upper blade 8.2 and the lower blade 8.1 on one side of the rivet, and a spring 8.3 on the other side of the rivet A connection wire 8.5 is provided between the upper blade 8.2 and the lower blade 8.1; one end of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com