High power liquid cooling led lamp

A LED lamp, high-power technology, applied in the direction of circuit heating device, loop fluid transportation, lighting and heating equipment, etc., can solve the problems of low thermal conductivity of the insulating layer, affect the service life of LED lamps, reduce the heat dissipation effect of LED lamps, etc., to achieve Ensure the insulation requirements and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

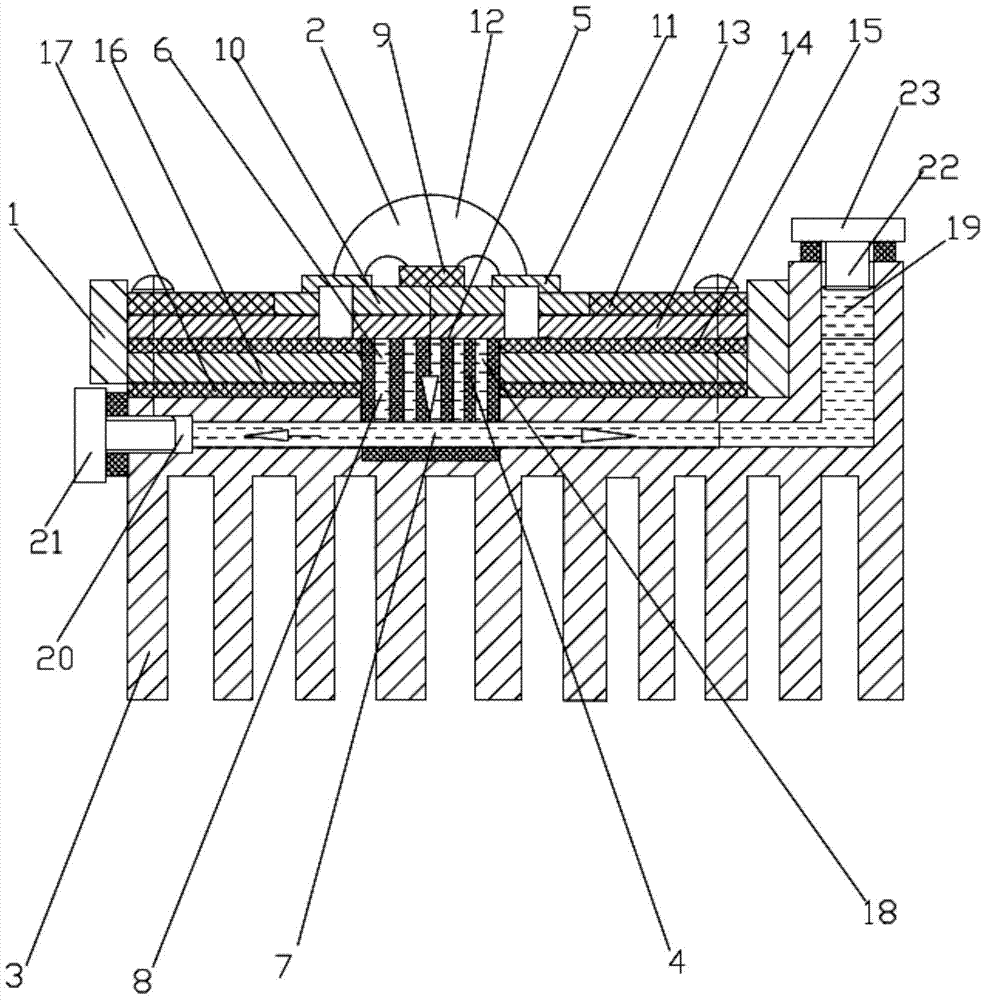

[0010] Below in conjunction with accompanying drawing, the present invention is further described:

[0011] figure 1 The schematic diagram of the structure of the high-power liquid cooling LED lamp is shown. The high-power liquid cooling LED lamp includes a bracket 1, LED2 and a cooling plate 3. The LED 2 is installed on the bracket 1, and the LED 2 is connected to the cooling plate 3. An insulated heat dissipation column 4 is provided between them, and the heat dissipation column 4 is in contact with the heat source position 5 of the LED2 and the heat dissipation plate 3. The heat dissipation column 4 is provided with a liquid guide hole 6, and the liquid guide hole 6 is provided with an insulating heat conduction oil 8, and the heat conduction oil 8 and the The heat source position 5 of the LED2 is in contact with the heat dissipation plate 3, and the heat of the heat source position 5 of the LED2 is transferred to the heat dissipation plate 3 through the heat dissipation co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com