Formula and making technology of soaked highland barley tea

A production process, highland barley tea technology, applied in tea substitutes, tea treatment before extraction, etc., can solve problems such as health impacts and unsafe consumption, and achieve the effects of mellow and natural smell, mellow taste, and healthy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

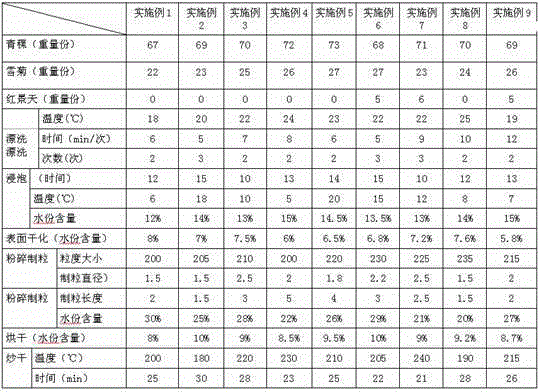

Embodiment 1-9

[0049]

[0050] Specific operation method two:

[0051] A kind of manufacturing process of steeping highland barley tea among the present invention, comprises the following steps:

[0052] (1) Selection of raw materials: select highland barley, and conduct pesticide residue detection on highland barley;

[0053] Specific testing steps: A. Select the sample and crush it, take 5g into a bottle with a cover, add 10ml of pure water and shake it 50 times, and let it stand for more than 2 hours; B. Take a piece of quick test card, tear off the upper cover film, and use Dip the white tablet with the extract and place it for more than 10 hours for pre-reaction. If possible, place it in a constant temperature device at 37°C for 10 hours. The surface of the pre-reaction tablet must be kept moist; C. Fold the quick test card in half and pinch it by hand for 3 hours Or use a constant temperature device for 3 hours to make the red tablet and the white tablet superimpose and react, and ...

Embodiment 10-18

[0065]

[0066] It can be seen from the above that the granules fried in stages in Examples 10-18 are less likely to disperse during the brewing process than the granules in Examples 1-9.

[0067] Control group: Other contents are as in Example 12, the soaking process is canceled during the preparation process, compared with the product in Example 12, after soaking for 7-8 hours, the tea soup in Example 12 is less turbid, and the granules are still relatively complete. The taste is mellow and mild. In the control group 1, more flocs were prone to appear, and the particles were mostly dispersed into fine powder, and the taste was rough.

[0068] Taste test: 400 people tested

[0069] The test results are: 98% think the color is beautiful; 96% think it is very fragrant or relatively fragrant; 99% have a moderate color; the tea soup is clear, and the particles are not easy to disperse after soaking 7-8 times. Accounted for 95%, 3% like it, 2% better, overall excellent and go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com