Stevioside-rich stevia rebaudianum tea and processing method thereof

A processing method and technology of steviol glycosides are applied to stevia tea rich in steviol glycosides and the processing field thereof, which can solve the problems of low glycoside content, heavy grassy taste, and difficulty in brewing, and achieve extended storage period, green leaf bottom, and convenience The effect of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

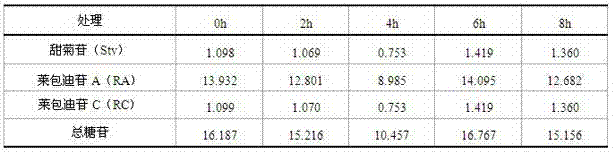

[0033] Embodiment 1: Spread the fresh stevia leaves in an environment of 20°C-35°C and a relative humidity of 65%-85% for 0h, 2h, 4h, 6h, 8h. The results showed that with the prolongation of the spreading time, the content of each component of steviol glycosides showed a trend of decreasing first and then increasing, and at 4 hours of spreading, the content of each component of steviol glycosides reached the minimum, and at 6 hours it reached At the highest level, the contents of stevioside, rebaudioside A, rebaudioside C, and total glycosides were 88.45%, 56.87%, 88.45%, and 60.34% higher than the lowest level, respectively. The effect of spreading on the glycoside content of stevia tea is shown in figure 1 .

Embodiment 2

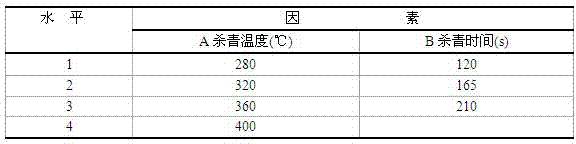

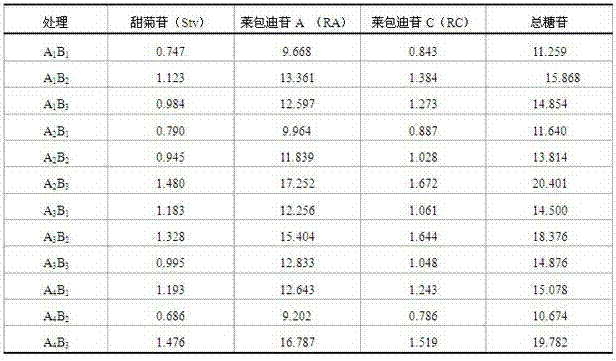

[0034] Embodiment 2: After the fresh leaves are spread out for 6 hours, they are fully mixed, and then they are fixed in a 6CST-30 type drum continuous cleaning machine. The temperature and time are two factors for the cleaning, four levels are set for the finishing temperature, and three are set for the finishing time. Level, random design was adopted, each treatment was repeated three times, each treatment used 2kg of fresh leaves, and other conditions were the same. See figure 2 .

[0035] The results showed that after the treatment at 280 ℃ for 120 s and 280 ℃ for 165 s, all the tea samples produced had green grass smell and a weak taste, which indicated that the green was not enough. The greening was done at 400°C, 165 s, and 400°C for 210 s, and the tea samples produced had a burnt smell, the color of the soup was dark, and the killing temperature was too high, which did not meet the quality requirements of famous and high-quality teas. However, the three treatments o...

Embodiment 3

[0036] Embodiment 3: the stevia leaves after finishing are placed in a kneading machine and kneaded. With the extension of rolling time, steviol glycosides showed a downward trend, that is, the content of each glycoside was high without rolling, and reached the minimum after rolling for 30 minutes, and the highest was 79.20%, 31.50%, 71.09%, and 33.69% higher than the lowest, respectively. Combined with the styling needs of the finished stevia tea, the kneading time is preferably 5-10 minutes. However, if the finished product has no styling requirements, it can directly enter the drying process without kneading. The effect of rolling time on the content of stevia tea glycosides, see Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com