Automatic spraying production line for automobile lamp anti-fogging paint

An automatic spraying and production line technology, applied in coatings, spray booths, spraying devices, etc., can solve the problems of low automation, unreasonable layout, and low work efficiency, and achieve high automation, novel structural design, and reasonable layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described below in conjunction with specific embodiments.

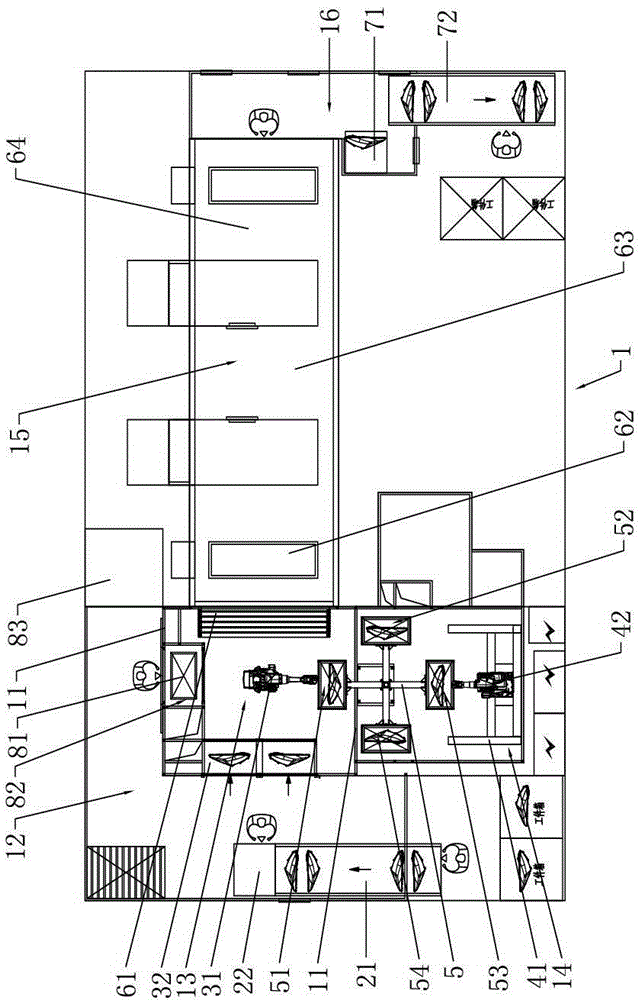

[0031] Such as figure 1 As shown, an automatic spraying production line for car light anti-fog paint includes a spraying room body 1, and the interior of the spraying room body 1 is provided with a constant temperature and humidity upper part room 12 separated by a middle partition 11, a constant temperature and humidity handling Room 13, automatic spraying room 14, spraying subsequent treatment room 15, constant temperature and humidity lower part room 16.

[0032] Further, an upper belt conveyor belt 21 is installed in the constant temperature and humidity upper piece chamber 12, and the feeding end of the upper piece belt conveyor belt 21 is positioned at the outside of the constant temperature and humidity upper piece chamber 12, and the unloading of the upper piece belt conveyor belt 21 The end is located in the constant temperature and humidity upper part room 12, the const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com