A numerically controlled device for intelligently repairing clogged ring dies

A technology of intelligent repair and ring die, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of high work intensity, shortened service life of ring die, high device cost, etc., to reduce energy consumption, Extended service life and high repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

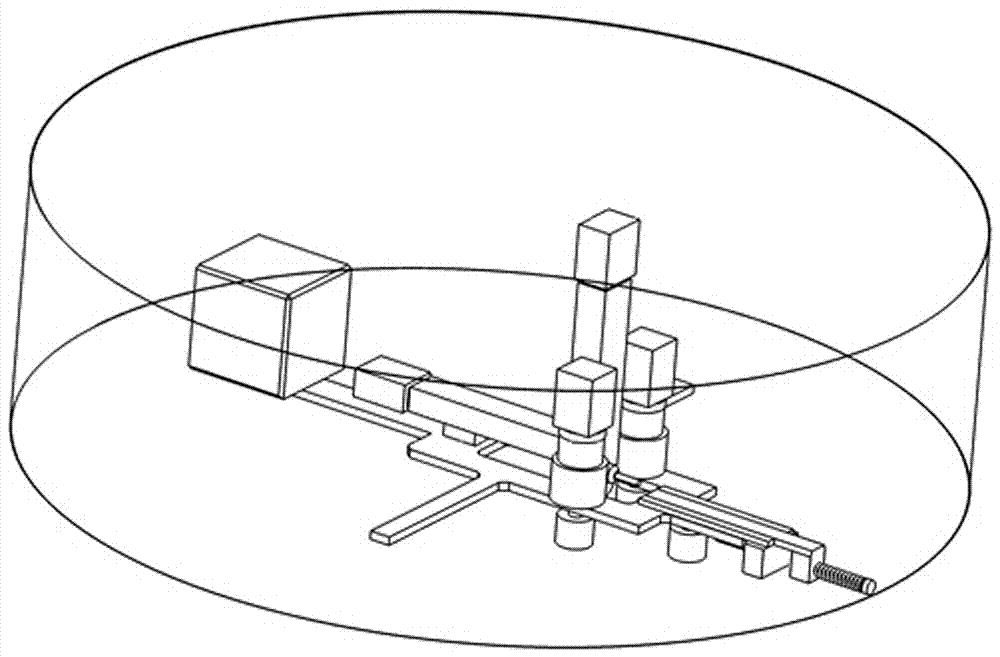

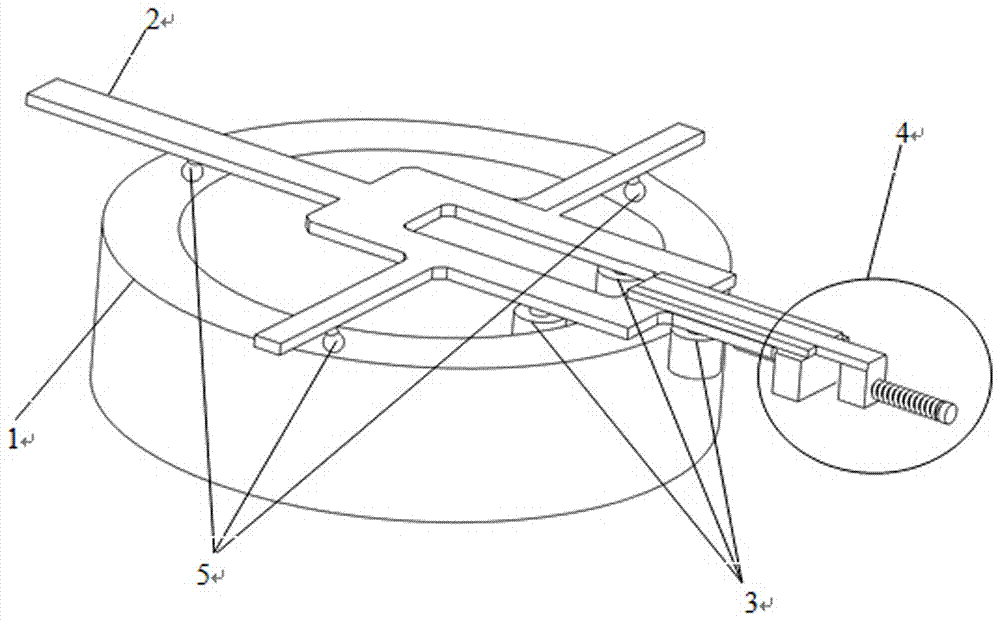

[0049] A numerically controlled intelligent repairing device for a blocked ring die, comprising a fuselage part, a drive part, a part for cleaning ring die holes, a control part and a sealing protection part, the drive part and the part for cleaning ring die holes are installed on the fuselage part, and the control parts are respectively It is connected with the driving part and the ring die hole cleaning part, and the fuselage part, the driving part, the ring die hole cleaning part and the control part are all placed in the sealing protection part.

[0050] The fuselage part includes a frame 2, a clamping mechanism 3, an adjusting mechanism 4 and a bull's-eye bearing 5, which are used to carry the entire repair device and clamp the repair device on the ring die 1.

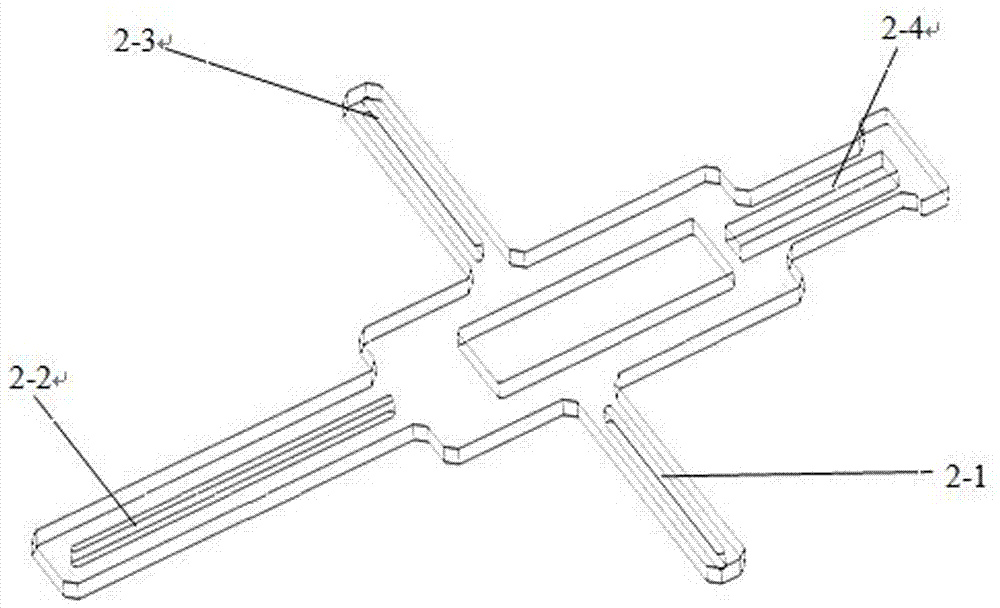

[0051] The frame 2 has a cross shape and is provided with a first U-shaped groove 2-1, a second U-shaped groove 2-2, a third U-shaped groove 2-3 and a fourth U-shaped groove 2-4.

[0052] The clamping mechanism 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com