Method for Resisting Welding of a First Component to a Second Component

A technology for resistance welding and components, which is applied in resistance welding equipment, energy storage discharge welding, welding power sources, etc., to achieve the effects of simplified method, simple cost, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

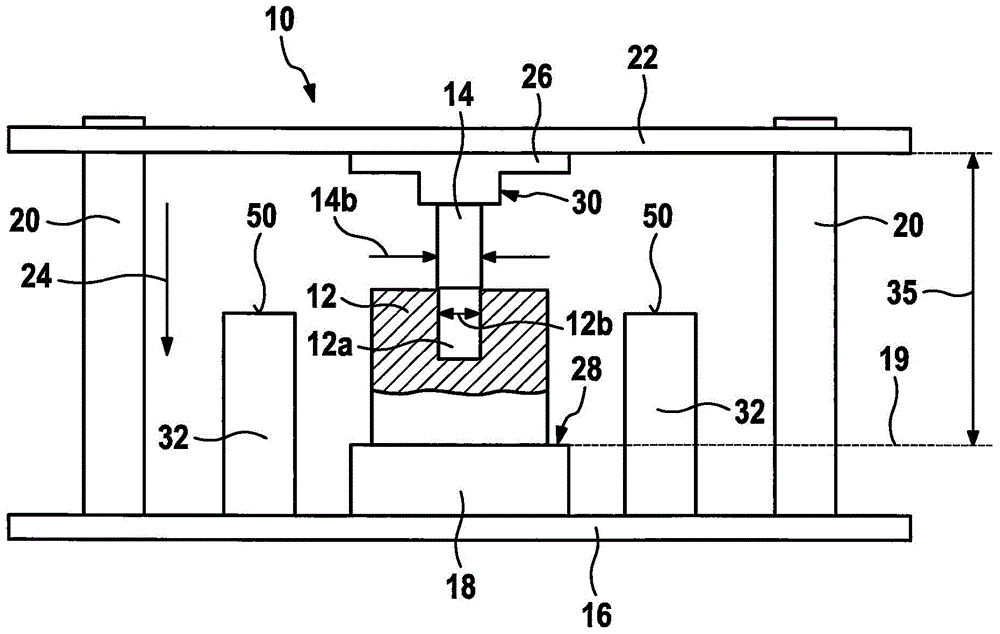

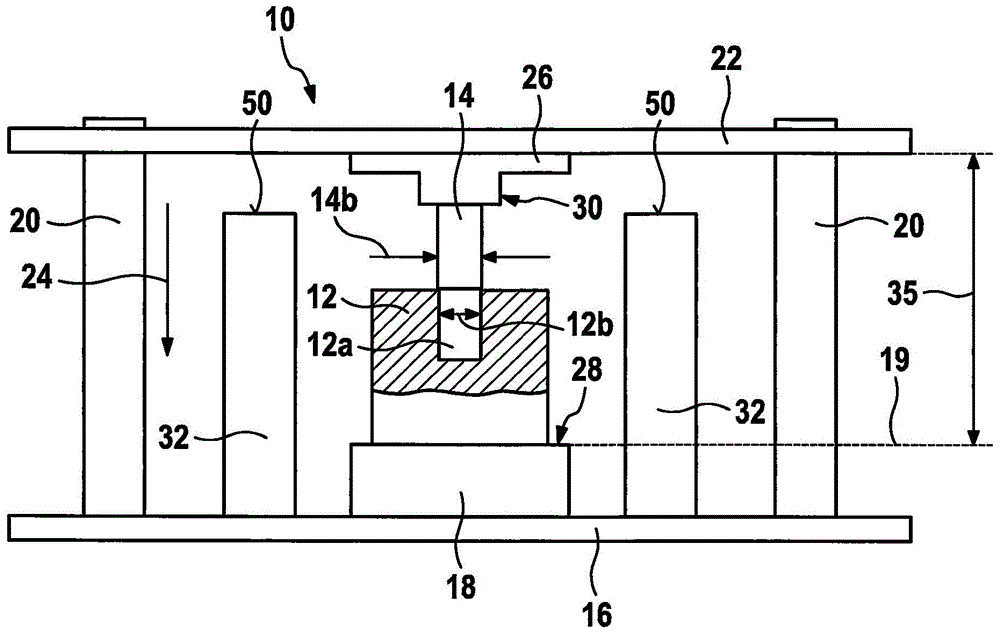

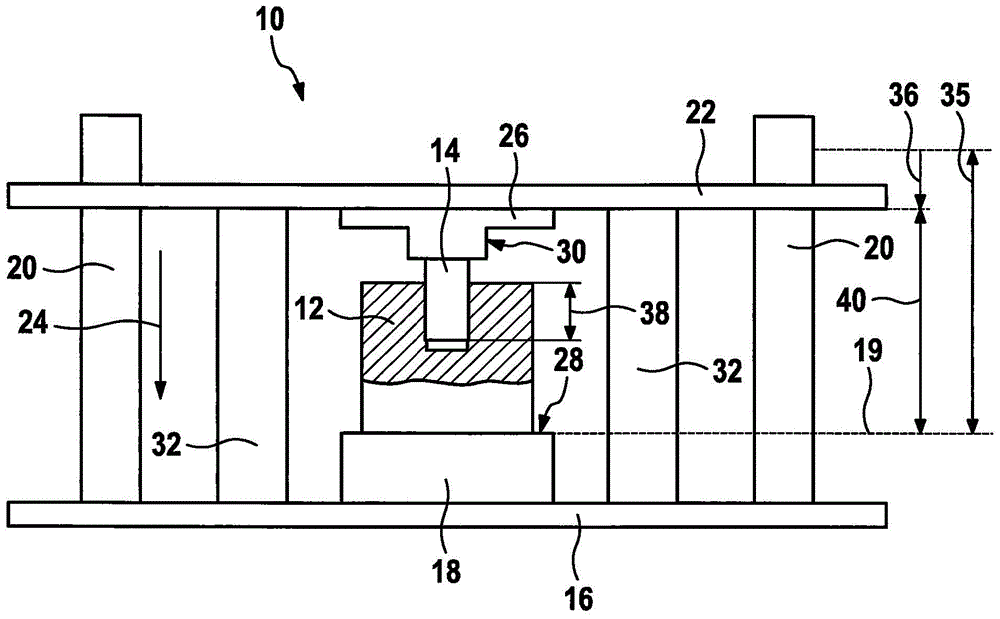

[0025] figure 1 A device 10 for resistance welding a first component 12 and a second component 14 is shown in a schematic sectional view. exist figure 1 The components shown in are arranged on a substrate 16, which is in figure 1 shown in the lower region of . The substrate 16 is presently embodied as a flat plate and is preferably an element of the device 10 .

[0026] Members 12 and 14 are made of metal and are electrically conductive. The first component 12 now has an opening 12 a which has an inner dimension 12 b in a direction perpendicular to an insertion direction 24 described below. The second component 14 has an outer dimension 14 b which is also defined perpendicularly to the insertion direction 24 and which is, for example, 0.1 mm to 1 mm (millimetres) larger than the inner dimension 12 b similarly to the press fit. The opening 12 a in the first component 12 represents, for example, an at least partially cylindrically shaped cavity. Correspondingly, the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com