Automatic welding device installation rack for V-shaped groove of ship T-shaped material and lifting method for automatic welding device installation rack

An automatic welding and hoisting method technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complex marine automatic welding process, no automatic welding, and difficulty in localization work, and achieves the solution The integration problem of automated welding equipment, the effect of facilitating the overall movement and shortening the handling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0058] This embodiment provides an installation stand for a complete set of automatic welding equipment for a V-groove of a ship's T-shaped profile.

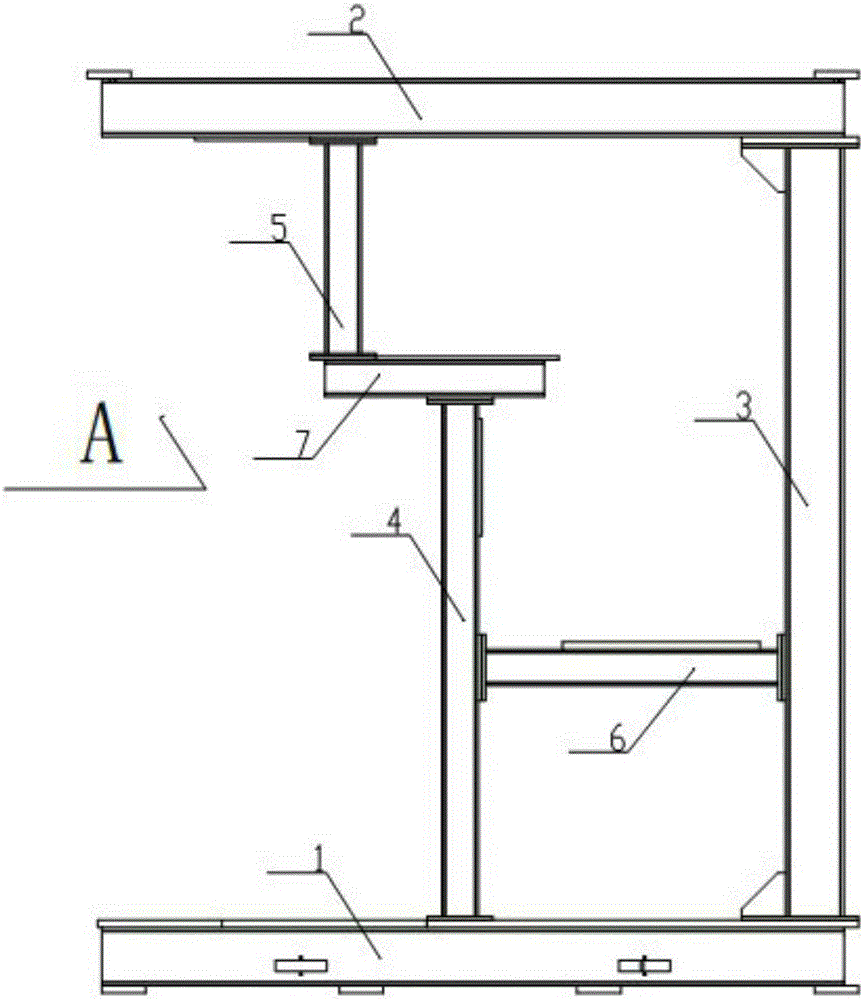

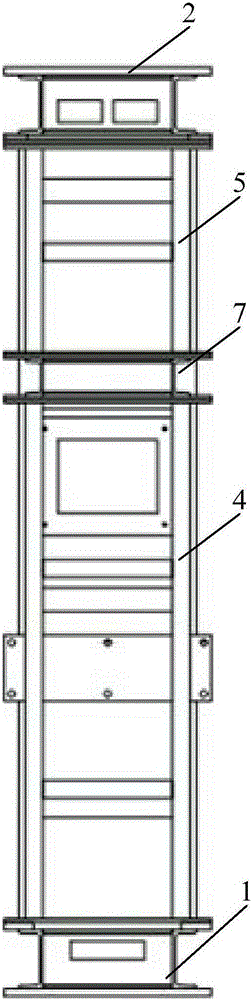

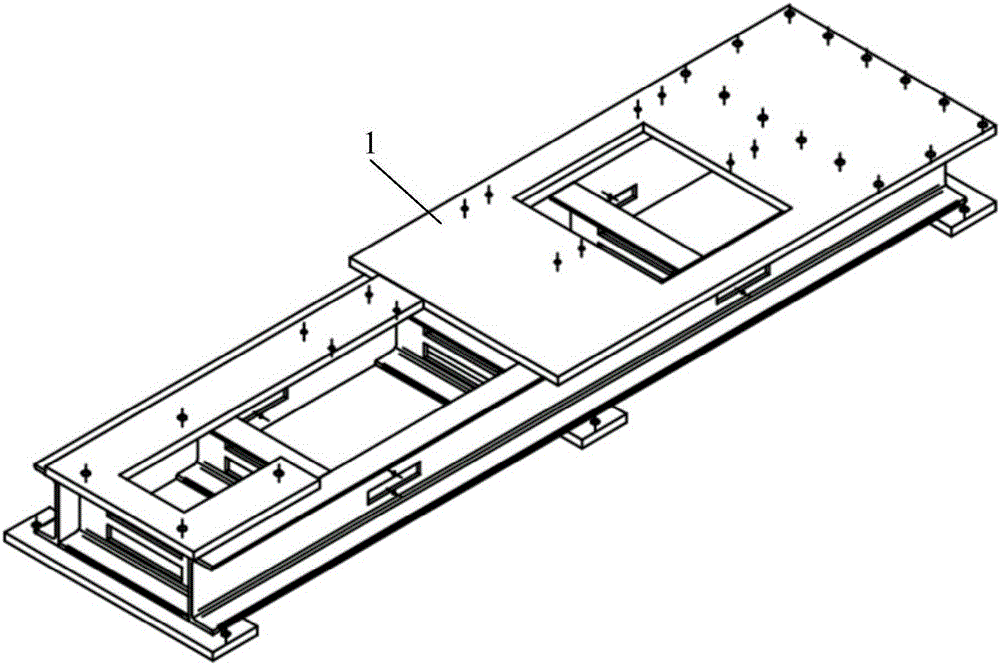

[0059] figure 1 It is a schematic diagram of the front view structure of the installation platform of the complete set of automatic welding equipment for the V-groove of the ship's T-shaped profile in the embodiment of the present invention. figure 2 It is a schematic diagram of the front view structure A-A of the installation platform of the complete set of automatic welding equipment for the V-groove of the ship's T-shaped profile in the embodiment of the present invention. Figure 3 ~ Figure 9 They are schematic structural diagrams of the base, left vertical beam, upright column, right vertical beam,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com