Insulating brick raw material stirring mechanism

A mixing mechanism and insulation brick technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems that the mixer cannot be moved for its own use, the influence of practicability and convenience, and the lack of mixing uniformity, etc., to achieve Improve practicability and convenience, long service life, good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

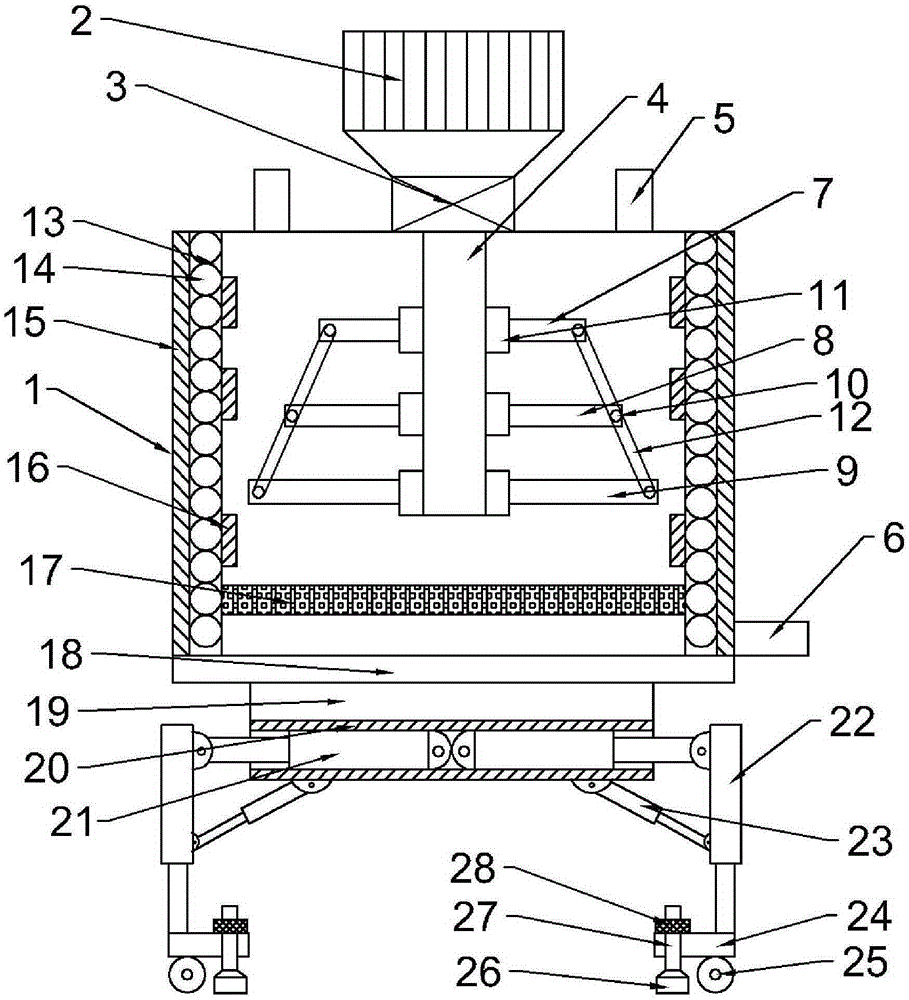

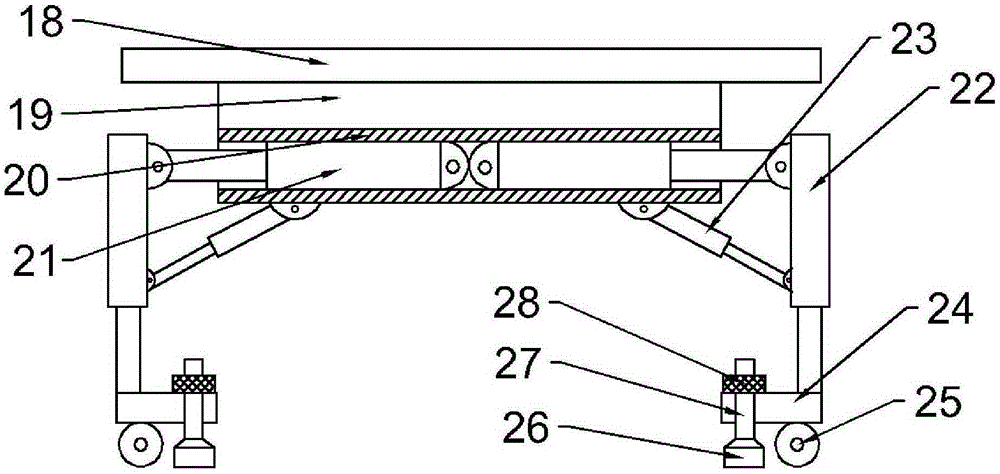

[0018] see Figure 1-2 , a raw material mixing mechanism for thermal insulation bricks, comprising a barrel body 1, a feed inlet 5 is arranged on the upper part of the barrel body 1, a frequency conversion motor 2 is arranged on the top of the barrel body 1, and a reducer is arranged between the frequency conversion motor 2 and the barrel body 1 3. The output part of the reducer 3 is connected with the stirring shaft 4, which extends to the center of the barrel body 1, and the surface of the stirring shaft 4 is provided with a first support frame 7, a second support frame 8 and a third support frame 9. The first support frame 7, the second support frame 8 and the third support frame 9 are fixed by connecting pieces 12, a layer of heating layer 13 is provided on the inner wall of the barrel body 1, and a plurality of baffles 16 are provided on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com